cnc lathe machine preventive maintenance checklist Lathe Maintenance Schedule. Keep your Haas machines running at peak performance while avoiding unplanned downtime. A maintenance program allows you to manage your schedule rather than getting caught with untimely surprises. This page shows the recommended maintenance intervals.

His 1099-R shows a taxable distribution in box 1 and 2 for fed taxes. However, box 16 (state distribution) does not show an amount. Does that mean this pension/retirement .

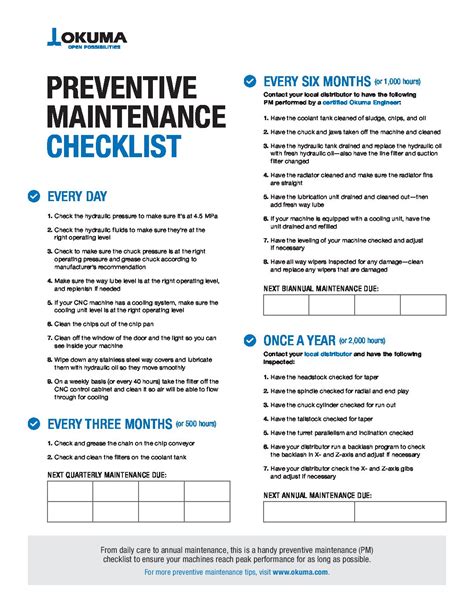

0 · okuma lathe maintenance checklist pdf

1 · okuma cnc machine maintenance checklist

2 · okuma cnc lathe maintenance

3 · okuma cnc lathe checklist

4 · lathe maintenance schedule

5 · lathe maintenance checklist pdf

6 · lathe cleaning schedule

7 · cnc lathe maintenance checklist

IP67 is an electrical enclosure rating signifying that an enclosure protects the device inside from the harmful effects of water and dust. It’s common to see IP67 ratings and IP68 ratings on consumer electronics, such as smartphones.

We will outline a checklist of daily maintenance tasks that should be performed to keep your CNC machine in peak condition, such as cleaning and lubricating components, inspecting cables .

daily and weekly basis to ensure the proper maintenance and performance of a Haas lathe can be achieved. Morning Tasks: Apply 3 pumps of grease to the hydraulic chuck at each zerk fitting. .Here are some preventive maintenance (PM) tips to help keep your CNC lathe running at peak performance while avoiding unplanned downtime. Download Our Preventive Maintenance Checklist Keep preventive maintenance top of mind.We will outline a checklist of daily maintenance tasks that should be performed to keep your CNC machine in peak condition, such as cleaning and lubricating components, inspecting cables and hoses, and checking coolant levels.

daily and weekly basis to ensure the proper maintenance and performance of a Haas lathe can be achieved. Morning Tasks: Apply 3 pumps of grease to the hydraulic chuck at each zerk fitting. Check hydraulic pressure gauges. Ensure they are set to the correct operating levels. Warm up spindle. Run spindle at 500 RPM for 5 min. Lathe Maintenance Schedule. Keep your Haas machines running at peak performance while avoiding unplanned downtime. A maintenance program allows you to manage your schedule rather than getting caught with untimely surprises. This page shows the recommended maintenance intervals.Your Preventive Maintenance Checklist (Schedule regular maintenance or servicing sessions, and maintain documentation of service/maintenance. Also, have a specific area for your employees to report issues.)This document provides a daily preventive maintenance check list for a CNC machine.

Lathe Preventative maintenance check list sheet for yearly and monthly pm's for machinery and cnc equipment. Machine preventive maintenance PM is critical or maximum machine uptime. View our basic lathe preventive maintenance schedule. CNC machine maintenance checklist for daily,weekly,monthly,half yearly and yearly inspection. 1-Ensure that the machine is clean near Chuck or spindle and Bed . 2-Check all cover or Guard for security. 3- Clean the slide rails like door or Cover. 1-Check indicator lights for all components. 2-Test all the emergency push button.Pm Checklist Okuma La The - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document outlines the findings and tasks completed as part of a preventive maintenance program on an Okuma lathe. It includes checks of various machine components like levels, backlash, spindle runout and alignment.

In this article, you will learn some of the best practices in checking, maintaining, and cleaning your CNC machine tools to keep them in optimal condition years after they are installed in your shop floor.Here are some preventive maintenance (PM) tips to help keep your CNC lathe running at peak performance while avoiding unplanned downtime. Download Our Preventive Maintenance Checklist Keep preventive maintenance top of mind.We will outline a checklist of daily maintenance tasks that should be performed to keep your CNC machine in peak condition, such as cleaning and lubricating components, inspecting cables and hoses, and checking coolant levels.daily and weekly basis to ensure the proper maintenance and performance of a Haas lathe can be achieved. Morning Tasks: Apply 3 pumps of grease to the hydraulic chuck at each zerk fitting. Check hydraulic pressure gauges. Ensure they are set to the correct operating levels. Warm up spindle. Run spindle at 500 RPM for 5 min.

Lathe Maintenance Schedule. Keep your Haas machines running at peak performance while avoiding unplanned downtime. A maintenance program allows you to manage your schedule rather than getting caught with untimely surprises. This page shows the recommended maintenance intervals.

Your Preventive Maintenance Checklist (Schedule regular maintenance or servicing sessions, and maintain documentation of service/maintenance. Also, have a specific area for your employees to report issues.)This document provides a daily preventive maintenance check list for a CNC machine.Lathe Preventative maintenance check list sheet for yearly and monthly pm's for machinery and cnc equipment. Machine preventive maintenance PM is critical or maximum machine uptime. View our basic lathe preventive maintenance schedule.

okuma lathe maintenance checklist pdf

CNC machine maintenance checklist for daily,weekly,monthly,half yearly and yearly inspection. 1-Ensure that the machine is clean near Chuck or spindle and Bed . 2-Check all cover or Guard for security. 3- Clean the slide rails like door or Cover. 1-Check indicator lights for all components. 2-Test all the emergency push button.Pm Checklist Okuma La The - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document outlines the findings and tasks completed as part of a preventive maintenance program on an Okuma lathe. It includes checks of various machine components like levels, backlash, spindle runout and alignment.

okuma cnc machine maintenance checklist

sheet metal milwaukee

sheet metal manufacturing process wiki

okuma cnc lathe maintenance

The local utility (in Massachusetts, if that helps) recently installed these things around several telephone poles in the area. They also recently dug around the base looking for rot/damage and screwed in some of those termite thingies. .

cnc lathe machine preventive maintenance checklist|lathe maintenance schedule