5 axis cnc machining pdf Programming dynamic 5-axis machining directly in SINUMERIK Operate Basics, possibilities, and limits Explore a wide range of our Used Stainless Steel Cabinets selection. Find top brands, exclusive offers, and unbeatable prices on eBay. Shop now for fast shipping and easy returns!

0 · what is 5 axis milling

1 · what does 5 axis mean

2 · small 5 axis cnc mill

3 · benefits of 5 axis machining

4 · 5 axis trunnion machining

5 · 5 axis machining explained

6 · 5 axis machining basics

7 · 5 axis cnc explained

Get the best deals for used sheet metal slitter at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

can you break metal boxes in crash bandicoot

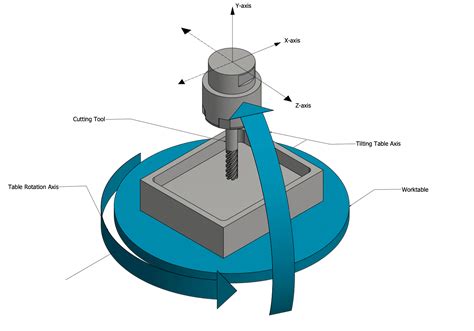

Modern machine tools, including the increasingly popular 5-axis machining center, place exacting demands on the CNC for exceptional speed, precision, and reliability. The CNC holds a large .Simplified 5-Axis Machining dptechnology.com 2 white paper What is 5-axis machining? Standard machines have linear motion along the X, Y and Z axes. 5-axis machines have two additional .

CNC Functions for 5-axis Machining. Fine Surface Finish. Smooth Tolerance + Control: • Smoothing tool center point (different algorithm) • Great for cutting 3D free surfaceIndexed 5-axis machining is great for fabricating components like housings, jigs, and fixtures. The process falls somewhere between 3-axis CNC milling and continuous 5-axis CNC machining .Programming dynamic 5-axis machining directly in SINUMERIK Operate Basics, possibilities, and limitsTake a high-quality 5-axis machines with exactly the same CNC hardware and basic software. Process the same example part, once using the traditional 5-axis machine-centric workflow, .

can you pain metal with fabric paint

A axis is equipment swing arm, C axis is equipment turret, to clamp.Automatic tuning of a total of 11 different kinds of geometric error, including spindle misalignment and inclination. The accuracy of 5-axis machines is measured in less than 10 minutes to draw .True 5-axis machining involves moving the part or the cutting tool along five different axes simultaneously. The most commonly used axes in CNC machining are the linear X, Y & Z .With multi-axis machining, the main objectives are to achieve perfect surface quality, precision, and speed without any need for remachining. Within this context, workflow is typically character-ized by the CAD-CAM-CNC process chain.

Modern machine tools, including the increasingly popular 5-axis machining center, place exacting demands on the CNC for exceptional speed, precision, and reliability. The CNC holds a large amount of data about the machining process and it all must be readily available to the operator.Simplified 5-Axis Machining dptechnology.com 2 white paper What is 5-axis machining? Standard machines have linear motion along the X, Y and Z axes. 5-axis machines have two additional axes of rotation. Most machine tool builders identify their rotary axes according to the ISO standard, which is that: • The A axis rotates around X

CNC Functions for 5-axis Machining. Fine Surface Finish. Smooth Tolerance + Control: • Smoothing tool center point (different algorithm) • Great for cutting 3D free surfaceIndexed 5-axis machining is great for fabricating components like housings, jigs, and fixtures. The process falls somewhere between 3-axis CNC milling and continuous 5-axis CNC machining (see below) in terms of speed, precision, and the ability to handle complex geometries.Programming dynamic 5-axis machining directly in SINUMERIK Operate Basics, possibilities, and limitsTake a high-quality 5-axis machines with exactly the same CNC hardware and basic software. Process the same example part, once using the traditional 5-axis machine-centric workflow, and once using the contemporary 5-axis part-centric workflow.

A axis is equipment swing arm, C axis is equipment turret, to clamp.Automatic tuning of a total of 11 different kinds of geometric error, including spindle misalignment and inclination. The accuracy of 5-axis machines is measured in less than 10 minutes to draw out maximum performance. With just a touch probe and datum sphere —auto tuning completed.

True 5-axis machining involves moving the part or the cutting tool along five different axes simultaneously. The most commonly used axes in CNC machining are the linear X, Y & Z-axes, but while 5-axis machining moves the tool back and forth (x-axis), in and out (y-axis), and up and down (z-axis), it can also rotate the part or tool at the same .

With multi-axis machining, the main objectives are to achieve perfect surface quality, precision, and speed without any need for remachining. Within this context, workflow is typically character-ized by the CAD-CAM-CNC process chain.Modern machine tools, including the increasingly popular 5-axis machining center, place exacting demands on the CNC for exceptional speed, precision, and reliability. The CNC holds a large amount of data about the machining process and it all must be readily available to the operator.Simplified 5-Axis Machining dptechnology.com 2 white paper What is 5-axis machining? Standard machines have linear motion along the X, Y and Z axes. 5-axis machines have two additional axes of rotation. Most machine tool builders identify their rotary axes according to the ISO standard, which is that: • The A axis rotates around X CNC Functions for 5-axis Machining. Fine Surface Finish. Smooth Tolerance + Control: • Smoothing tool center point (different algorithm) • Great for cutting 3D free surface

Indexed 5-axis machining is great for fabricating components like housings, jigs, and fixtures. The process falls somewhere between 3-axis CNC milling and continuous 5-axis CNC machining (see below) in terms of speed, precision, and the ability to handle complex geometries.Programming dynamic 5-axis machining directly in SINUMERIK Operate Basics, possibilities, and limitsTake a high-quality 5-axis machines with exactly the same CNC hardware and basic software. Process the same example part, once using the traditional 5-axis machine-centric workflow, and once using the contemporary 5-axis part-centric workflow.

A axis is equipment swing arm, C axis is equipment turret, to clamp.Automatic tuning of a total of 11 different kinds of geometric error, including spindle misalignment and inclination. The accuracy of 5-axis machines is measured in less than 10 minutes to draw out maximum performance. With just a touch probe and datum sphere —auto tuning completed.

what is 5 axis milling

what does 5 axis mean

small 5 axis cnc mill

$143.48

5 axis cnc machining pdf|5 axis cnc explained