electrical box to close stud to center light Pull the fixture wires into the electric box and make connections. Twist a wire cap onto each pair of wires you connect and push the caps into . A typical example of NEMA 4 enclosure would be a metal box used for electrical controls in a lab or any indoor environment that is dry and there is no dripping pipes and rain. NEMA 4 Enclosures are typically lower cost enclosures made from sheet metal or plastic.

0 · stud in wall where elect box

1 · off center electrical boxes

2 · light box with stud right

3 · how to center a light fixture

4 · hanging electrical box in wall

5 · elect box wall stud problems

6 · elect box wall light stud

7 · diy light box on stud

A WPS and PQR are required documents in the fabrication process when a weld must comply with a certain standard. In simple terms, a WPS is a set of welding instructions and the PQR is a checklist to ensure those instructions were satisfactorily met.

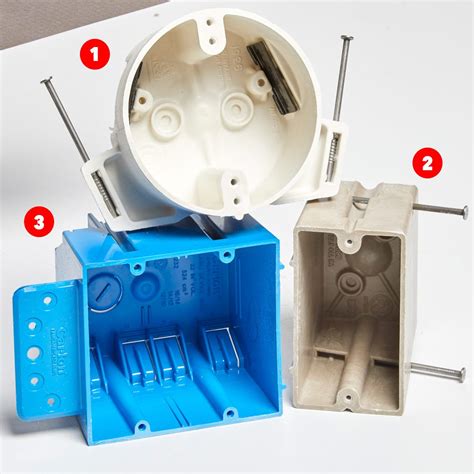

Problem is- exactly where I want to put the electrical box to hang the wall light is a wall 2×4 stud. what can I do – use one of those thinner electrical boxes and cut out part of the . Pull the fixture wires into the electric box and make connections. Twist a wire cap onto each pair of wires you connect and push the caps into . I was wondering, not sure if it's a local code thing or not, if a non-load bearing stud can be notched for a light box on a wall? I'm trying to center a lamp right over the middle of a . There is a 4" plastic electrical box made with a cut out that offsets the enter nipple more toward the joist. Commonly used for hanging fans when a joist falls center of a dining .

Install a new-work box against the stud. Inspect. Install drywall. Once you're all done and passed all your inspections, install an old-work box in the correct .

Forget about centering the box and buy a light with a base big enough to cover the uncentered box while the light itself is still centered. Your idea for a "simple as two cross beams and a horizontal mini stud between them?" will work. You could use an old work box. It is designed to be used to install a box in .

The common method for dealing with this situation is to cut a piece of material that is nominally the same type of material as the studs and nail it between the studs as blocking. The electrical box is in turn mounted to the .Here's why: the electrical box is against a stud, so not movable. You could cut a new hole and somehow put a block extending the box out from the stud, but then you'd have to patch the old .

stud in wall where elect box

Problem is- exactly where I want to put the electrical box to hang the wall light is a wall 2×4 stud. what can I do – use one of those thinner electrical boxes and cut out part of the face of the stud with Mr Sawzall? Or use a round 1/2" deep pan box & cut out drywall only and mount to the stud surface . Pull the fixture wires into the electric box and make connections. Twist a wire cap onto each pair of wires you connect and push the caps into the box. Secure the feature to the wall or ceiling by driving screws into the ceiling rafters or . I was wondering, not sure if it's a local code thing or not, if a non-load bearing stud can be notched for a light box on a wall? I'm trying to center a lamp right over the middle of a sink, and unfortunately, there is a stud right there.

There is a 4" plastic electrical box made with a cut out that offsets the enter nipple more toward the joist. Commonly used for hanging fans when a joist falls center of a dining room table. Should work for a conflicting stud as well.

Install a new-work box against the stud. Inspect. Install drywall. Once you're all done and passed all your inspections, install an old-work box in the correct location and fix the drywall.

Forget about centering the box and buy a light with a base big enough to cover the uncentered box while the light itself is still centered. Your idea for a "simple as two cross beams and a horizontal mini stud between them?" will work. You could use an old work box. It is designed to be used to install a box in existing drywall where no stud is available to attach too. Here is tutorial. The common method for dealing with this situation is to cut a piece of material that is nominally the same type of material as the studs and nail it between the studs as blocking. The electrical box is in turn mounted to the added cross piece.Here's why: the electrical box is against a stud, so not movable. You could cut a new hole and somehow put a block extending the box out from the stud, but then you'd have to patch the old hole and repaint.

cnc machining tooling

cnc machining turning manufacturers

If you bolt the box to the strut then none of the conduit will be flush with the strut, so to use the straps that hold the conduit to the strut you would need a kick. I think this is what post 9 is about, using standoff mounting for the conduit straps.

electrical box to close stud to center light|light box with stud right