cnc machine for hdpe Preparing Your CNC Machine for HDPE. Select the Appropriate Tools: Use plastic machining tools meant for the job, such as carbide end mills or router bits with sharp cutting . Your local electrical code may allow you to place a junction box in the attic. Check with the permitting office before you do this. Metal boxes are stronger, so they will resist damage better than plastic boxes.

0 · machining hdpe material

1 · how to bend hdpe sheet

2 · hdpe manufacturing process

3 · hdpe machinability

4 · hdpe feeds and speeds

5 · hdpe cutter machine

6 · hdpe cnc feeds and speeds

7 · cnc router hdpe

Search our network of job shops and contract manufacturers. Injection .

CNC HDPE machining has lots of challenges but plays an irreplaceable role in precise, intricate parts production, before choosing a . CNC Machining HDPE Plastics Parts. CNC machining is a plastic manufacturing process involving cutting tools mounted on a CNC machine and controlling them using g . Preparing Your CNC Machine for HDPE. Select the Appropriate Tools: Use plastic machining tools meant for the job, such as carbide end mills or router bits with sharp cutting . Understanding the HDPE CNC machining process is essential since it can pose limitless challenges that can hinder the success of your project. This guide discusses HDPE thermoplastic and its properties, standard .

machining hdpe material

how to bend hdpe sheet

Below are the primary methods used to machine HDPE, along with a brief explanation of their benefits: CNC Milling: It is particularly preferred for its capacity in cutting and creating intricate shapes of the HDPE. CNC .Learn everything you need to know about CNC machining HDPE, from its properties and surface finishes to design tips and common questions answered. Discover how to optimize your HDPE parts for CNC machining and avoid .Experience the versatility and strength of our HDPE CNC Machining Service to create custom high-density polyethylene parts. Get HDPE components that meet the highest standards of accuracy and quality for various applications.

CNC HDPE machining has lots of challenges but plays an irreplaceable role in precise, intricate parts production, before choosing a material for your product or starting production, learn about HDPE properties and uses, High-density polyethylene definition, as well as how to CNC machine HDPE.

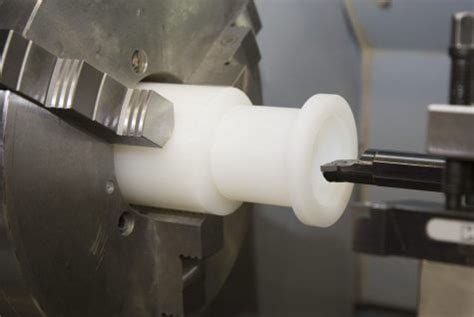

CNC Machining HDPE Plastics Parts. CNC machining is a plastic manufacturing process involving cutting tools mounted on a CNC machine and controlling them using g-codes and m-codes (which carry instructions for the tool’s movement) to create machine parts.. Depending on the project, there are many CNC machining techniques, each with advantages . Preparing Your CNC Machine for HDPE. Select the Appropriate Tools: Use plastic machining tools meant for the job, such as carbide end mills or router bits with sharp cutting edges. Tools with a higher rake angle can improve performance by ensuring clean cuts and minimizing HDPE melting. Discover the key aspects of machining High Density Polyethylene (HDPE), a versatile thermoplastic polymer, with AIP Precision Machining's expert guide. Learn about the material's properties, machining techniques, and applications in various industries including aerospace and medical devices.

expanded metal sheet structural

hdpe manufacturing process

expanded metal sheet dimensions

Understanding the HDPE CNC machining process is essential since it can pose limitless challenges that can hinder the success of your project. This guide discusses HDPE thermoplastic and its properties, standard machining processes, and the benefits of HDPE-machined parts. Below are the primary methods used to machine HDPE, along with a brief explanation of their benefits: CNC Milling: It is particularly preferred for its capacity in cutting and creating intricate shapes of the HDPE. CNC Routing: Suitable for cutting out cavities in HDPE, CNC routing is most effective when used in a production environment.Learn everything you need to know about CNC machining HDPE, from its properties and surface finishes to design tips and common questions answered. Discover how to optimize your HDPE parts for CNC machining and avoid common mistakes.Experience the versatility and strength of our HDPE CNC Machining Service to create custom high-density polyethylene parts. Get HDPE components that meet the highest standards of accuracy and quality for various applications.

HDPE: CNC Machining Materials Overview. HDPE is a plastic with a good strength-to-density ratio used for various purposes. Learn how to CNC machine HDPE, how to set up your ZMorph VX and Voxelizer, and what are the most common applications.

CNC machining of HDPE can offer many benefits such as high accuracy, fast production, cost-effectiveness, and flexibility. By choosing the right type and grade of HDPE for your application, you can enhance your product quality and performance. CNC HDPE machining has lots of challenges but plays an irreplaceable role in precise, intricate parts production, before choosing a material for your product or starting production, learn about HDPE properties and uses, High-density polyethylene definition, as well as how to CNC machine HDPE. CNC Machining HDPE Plastics Parts. CNC machining is a plastic manufacturing process involving cutting tools mounted on a CNC machine and controlling them using g-codes and m-codes (which carry instructions for the tool’s movement) to create machine parts.. Depending on the project, there are many CNC machining techniques, each with advantages .

Preparing Your CNC Machine for HDPE. Select the Appropriate Tools: Use plastic machining tools meant for the job, such as carbide end mills or router bits with sharp cutting edges. Tools with a higher rake angle can improve performance by ensuring clean cuts and minimizing HDPE melting. Discover the key aspects of machining High Density Polyethylene (HDPE), a versatile thermoplastic polymer, with AIP Precision Machining's expert guide. Learn about the material's properties, machining techniques, and applications in various industries including aerospace and medical devices. Understanding the HDPE CNC machining process is essential since it can pose limitless challenges that can hinder the success of your project. This guide discusses HDPE thermoplastic and its properties, standard machining processes, and the benefits of HDPE-machined parts.

hdpe machinability

Below are the primary methods used to machine HDPE, along with a brief explanation of their benefits: CNC Milling: It is particularly preferred for its capacity in cutting and creating intricate shapes of the HDPE. CNC Routing: Suitable for cutting out cavities in HDPE, CNC routing is most effective when used in a production environment.

Learn everything you need to know about CNC machining HDPE, from its properties and surface finishes to design tips and common questions answered. Discover how to optimize your HDPE parts for CNC machining and avoid common mistakes.

Experience the versatility and strength of our HDPE CNC Machining Service to create custom high-density polyethylene parts. Get HDPE components that meet the highest standards of accuracy and quality for various applications.

HDPE: CNC Machining Materials Overview. HDPE is a plastic with a good strength-to-density ratio used for various purposes. Learn how to CNC machine HDPE, how to set up your ZMorph VX and Voxelizer, and what are the most common applications.

extend 3inch electrical box

I’d like to put a quick change gearbox on my 1947 Logan made PowrKraft 10” lathe. I understand that the 1201 of LA 1201 Logan gearbox is what I need. It came on Logan 10”, 11”, and 2900 series 12” lathes and will need about 11/32” milled off of the mounting surface to account for lead screw location.

cnc machine for hdpe|hdpe cnc feeds and speeds