cnc milling machine parts and their function CNC machines perform incredible tasks that efficiently produce intricate components, surpassing traditional machining methods in both precision and cost-effectiveness. In this article, we’ll take a high-level look at CNC machine . The WD Passport Metal is more design-oriented. It has a metal enclosure and it's all about that. You can choose from the 1 TB, 2 TB or 3 TB capacities. It also comes equipped .

0 · schematic diagram of cnc machine

1 · parts made by cnc machine

2 · milling machine diagram labelled

3 · cnc milling machine parts names

4 · cnc milling machine diagram

5 · cnc mill parts diagram

6 · cnc machine components list

7 · block diagram of cnc machine

$16.98

Parts of a CNC milling machine include a column, base, knee, power feed mechanism, a work table, ram, spindle, milling tool, milling chuck, CNC controller, and an overhanging arm along with arbor support in case of . Gather detailed information from reputable sources on the various parts of a CNC milling machine, their functions, and their significance in the machining process. Learn how milling machine parts are used, surface . Although the milling operations on the two styles of milling machines might vary, the milling machine parts that make them up have much in common. We’ve created a list of the essential parts of a CNC milling machine . In this article, I have covered the standard CNC milling parts, tools commonly used with the machine, factors affecting the cost of a CNC mill, and how CNC machining works. I hope that you’ve got the basics of this important .

schematic diagram of cnc machine

parts made by cnc machine

CNC machines perform incredible tasks that efficiently produce intricate components, surpassing traditional machining methods in both precision and cost-effectiveness. In this article, we’ll take a high-level look at CNC machine . The main parts include the base, column, knee, saddle, table, spindle, and cutting tools. The base provides a sturdy foundation for the entire machine, while the column supports the knee and houses the drive .

Explore the features, specifications, and industry applications of the Acer 1440G CNC machine. Learn how it serves various industries and the kind of parts it can produce. . The Acer 1440G is a type of CNC milling machine optimized for a range of delicate tasks. This machine functions primarily in industries like automotive, aerospace, and .

A CNC milling machine consists of several key components that work together to precisely machine metal parts.. Spindle. The spindle is the main component that does the cutting. It spins a cutting tool like an end mill, drill, or .

Here’s a closer look at the primary types of CNC machines and their applications. CNC Machining Centers (Milling) CNC milling machines are among the most versatile and widely used in the industry. They operate by rotating a cutting tool against a stationary workpiece, allowing for intricate shapes and designs to be crafted with high precision . Parts of CNC Machine + Function - Some significant components and elements that contribute to the machine's efficacy are present in machine tools with CNC systems. . You can also visit our CNC Milling Machines Suppliers and Companies to find out a complete list of CNC machine products and suppliers. . Parts of Boiler and Their Function in . With their versatility, speed, precision, and consistency, CNC milling machines have become indispensable in various industries. Their ability to produce high-quality components with speed and precision makes them an excellent choice for manufacturers seeking to optimize their production processes and deliver superior products.

Understanding the different parts and functions of a CNC machine is crucial for anyone involved in its operation or interested in the field of machining. In this blog post, we will delve into the intricacies of CNC machine parts and their functions, providing you with a comprehensive guide to demystify this fascinating technology. 1. Control .

CNC Milling Machine. CNC milling is a machining process that uses computerized controls and rotating multipoint cutting tools to produce custom-designed parts or products. These machines operate on three to five axes, creating slots, holes, and details in materials to turn them into vehicles or mechanical parts. Here are the 15 main parts of a CNC machine and their functions: Control Panel – The control panel is the interface between the operator and the machine. It allows the operator to input commands and control the machine’s movements. Spindle – The spindle is the rotating component that holds the cutting tool. It rotates at high speeds to .This article highlighted key aspects of milling machines, including their types, functions, and applications. Understanding vertical, horizontal, CNC, and universal milling machines can help optimize production processes. We encourage you to .Tolerances are specified to ensure that CNC machined parts meet design requirements and function correctly in their intended applications. They are typically expressed as a permissible deviation from a specified dimension, such as ±0.01 inches. Tight tolerances mean less variation, while looser tolerances allow for more variation.

CNC milling is a subtractive manufacturing process that uses computer-controlled machines to remove material from a workpiece to create the desired shape. This process is highly precise and can produce complex parts with tight tolerances. Common types of CNC machines include; CNC lathe machines, CNC milling machines, CNC routers, 3D printers . Basic Parts of CNC Milling Machines. Although the parts of different CNC mills differ based on the type, capacity, and manufacturer. These parts help to understand how the CNC milling processes work. A standard CNC mill comprises these parts: Knee: The knee is an adjustable component attached to the column. It can be raised or lowered on the Z . When addressing the types of CNC milling tools and their uses, it is essential to understand the diversity and specificity each tool brings to machining operations. . The function of the tool changer in CNC milling is to automate the process of switching between different cutting tools as required by the machining operations. This system .

milling machine diagram labelled

That being said, every CNC milling machine will have some basic components to perform the device’s primary function. This article takes a quick stab at the basic parts of a CNC milling machine, their function, and their possible location. In no particular order, here is a rundown of the standard and most common parts of a CNC milling machine .

Understanding the various parts and their functions is crucial for anyone working with CNC machines. In this blog post, we will take an in-depth look at the key components of CNC machines and their functions. Table of Contents:\ I. Introduction to CNC Machines\ II. The Main Parts of CNC Machines\ A. Spindle\ B. Tool Changer\ C. Worktable\15. Table Power Feed: ( Parts of Milling Machine ) The role of the table power feed is to adjust or change the table utilizing power by rotating or turning the accessible lever. 16. Machine Vice: ( Parts of Milling Machine ) A clamping .

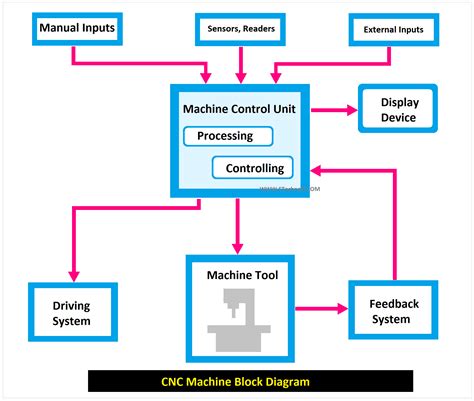

This article will describe the different parts of a CNC machine. Some parts are common between lathes and mills, like the control unit, driving system, and feedback system, while others are specific to a certain type of .

CNC (Computerized Numerical Control) machining is a technology that allows machines to perform precise cutting, engraving, drilling, or milling operations based on preset instructions, m-code is a component of the CNC programming language used to control various functions during the machining process. This article provides a comprehensive understanding . Understanding the Function of a Spindle in CNC Milling. The spindle is one of the most important parts of a CNC milling machine that provides power to maneuver and cut material. It consists basically of a rotary shaft, which is driven by an electric motor that rotates at high-speed giving torque for effective interaction with the workpiece .What are the Parts of a CNC Machine? Bed: Typically constructed from cast iron for enhanced durability and strength, the bed is the machine’s foundation, supporting all components.. Spindle: Inside the machining area, the electrically driven spindle rotates tools that cut and shape the parts. The inside of the spindle is tapered to match the tapered angle of the tool holder to . Welcome to a fascinating journey into the inner workings of CNC machines! In this article, we will take a detailed look at the anatomy of a CNC machine, exploring its main parts and functions. Whether you are a seasoned CNC operator or someone new to

CNC Milling Machines: First, CNC milling machines use rotary cutting tools to remove material from a workpiece and make it into a shape or form that the user wants. These CNC machines help cut, shape, and drill different kinds of materials. They are often used to make precise and complicated parts. Key Components: CNC Machine Parts By Type of Technology. CNC machines can be classified by their technological capabilities. Each type uses different parts to achieve specific machining operations. Below, we will discuss the components of 3-axis and 4-axis CNC machines. 3-Axis CNC Machines. 3-axis CNC machines are the most common type used in various industries. A CNC milling machine is a marvel of engineering, combining various components to transform raw material into intricate shapes and designs. The machine control unit (MCU) is pivotal in managing the machine’s movements and operations, while the core components function in unison to enable efficient operation and accurate cnc machine work capabilities. Understanding these parts and their functions is crucial for efficient and safe operation of a milling machine. The milling machine is a powerful tool used for cutting and shaping metals. Understanding the anatomy and functions of its various parts is essential for efficient and precise machining.

Read more: Components and Functions of a CNC Machine Function . A CNC machine is basically a sophisticated tool that translates digital instructions into precise physical movements. It allows the user to interface with . The primary functions of a CNC machine include: Digital Control: Computer programs that dictate the tool’s movements and .

$16.98

cnc milling machine parts and their function|parts made by cnc machine