countersink in sheet metal Countersinks are conical holes cut or formed into precision sheet metal parts that allow hardware to sit flush with the material. Here’s everything . 7 Steps Of Thin Metal Welding With A Stick Welder: Knowing the full process of stick welding will enable you to weld a piece of thin metal well. Below I have described the full process step by step of thin metal welding.

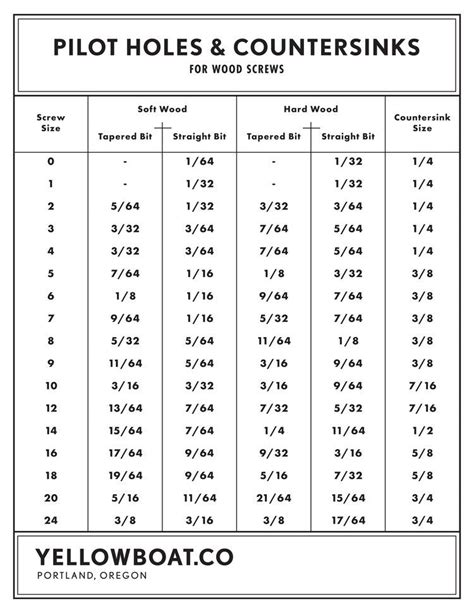

0 · what size countersink chart

1 · countersinking screws in metal

2 · countersink size for #8 screw

3 · countersink size chart metal

4 · best countersinks for metal

5 · 90 degree countersink chart

6 · 82 vs 100 degree countersink

7 · 100 deg countersink dimension chart

Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt.

what size countersink chart

Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the .Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the . Countersinks are conical holes cut or formed into precision sheet metal parts that allow hardware to sit flush with the material. Here’s everything .

Discover UniPunch's countersinking solutions for efficient metal fabrication. Enhance your production with our innovative tooling systems.

countersinking screws in metal

countersink size for #8 screw

Countersinking is a method of creating a conical hole in a sheet metal piece, allowing for the flush attachment of fasteners like screws or bolts. Important: Larger countersinks in thinner .From cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. This article will explore what countersink holes are, their uses, and how to apply ANSI standards to create .Find design guidelines for your CAD files to specify countersinking in your sheet metal & composite parts. Major/Minor depth charts & more.

Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best .

Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best . Countersinks are conical holes cut or formed into precision sheet metal parts that allow hardware to sit flush with the material. Here’s everything you need to know about designing countersinks, including Approved Sheet Metal’s proprietary formula for .Discover UniPunch's countersinking solutions for efficient metal fabrication. Enhance your production with our innovative tooling systems.

Countersinking is a method of creating a conical hole in a sheet metal piece, allowing for the flush attachment of fasteners like screws or bolts. Important: Larger countersinks in thinner materials will enlarge the inner hole diameter.From cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. This article will explore what countersink holes are, their uses, and how to apply ANSI standards to create precise, flush finishes in manufacturing.

playstation long box metal gear solid

Find design guidelines for your CAD files to specify countersinking in your sheet metal & composite parts. Major/Minor depth charts & more.

Countersink holes and countersink compatible fasteners are used in all sorts of products and projects. From cellphones and computers to industrial equipment and cabinets, countersinking is used for machining metal stock, wood, sheet-metal, and even PCBs.Creating a countersink hole in a metal workpiece involves selecting the right countersink bit, marking the location, drilling a pilot hole, and then using the countersink bit to enlarge the top part of the hole to accommodate a screw head flush with the surface. Curious about the nitty-gritty of getting those sleek, flush screw fittings in metal? Check out our list of quick tips and tolerance specifications for designing Sheet Metal countersinks, curls, and hems! And for even more information, download our free Sheet Metal Design Guide! The maximum depth of a countersink .Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best .

Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best . Countersinks are conical holes cut or formed into precision sheet metal parts that allow hardware to sit flush with the material. Here’s everything you need to know about designing countersinks, including Approved Sheet Metal’s proprietary formula for .

Discover UniPunch's countersinking solutions for efficient metal fabrication. Enhance your production with our innovative tooling systems.Countersinking is a method of creating a conical hole in a sheet metal piece, allowing for the flush attachment of fasteners like screws or bolts. Important: Larger countersinks in thinner materials will enlarge the inner hole diameter.From cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. This article will explore what countersink holes are, their uses, and how to apply ANSI standards to create precise, flush finishes in manufacturing.

Find design guidelines for your CAD files to specify countersinking in your sheet metal & composite parts. Major/Minor depth charts & more.

Countersink holes and countersink compatible fasteners are used in all sorts of products and projects. From cellphones and computers to industrial equipment and cabinets, countersinking is used for machining metal stock, wood, sheet-metal, and even PCBs.

Creating a countersink hole in a metal workpiece involves selecting the right countersink bit, marking the location, drilling a pilot hole, and then using the countersink bit to enlarge the top part of the hole to accommodate a screw head flush with the surface. Curious about the nitty-gritty of getting those sleek, flush screw fittings in metal?

countersink size chart metal

BBB Directory of Sheet Metal Fabrication near West Creek, NJ. BBB Start with Trust ®. Your guide to trusted BBB Ratings, customer reviews and BBB Accredited businesses.

countersink in sheet metal|90 degree countersink chart