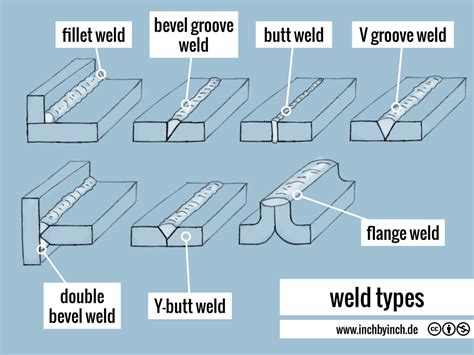

how to weld sheet metal in inventor Inventor supports various welding types, including fillet welds, groove welds, spot welds, and more. Familiarize yourself with these different weld types and their applications..more.

Shop Our Inventory Of Underground Enclosures Online. Graybar Is Your Trusted Distributor For Enclosures.

0 · inventor welding types

1 · inventor welding modeling

2 · inventor welding instructions

3 · inventor welding

4 · inventor steel welding tutorial

13.5W LED Under Cabinet Light Bar; 24 inches in length; 3000K; 1050 Lumens; 120V

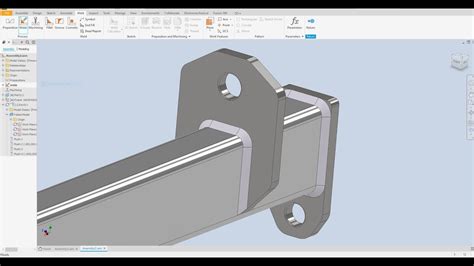

The welding capabilities within Inventor are currently limited to parts within a weldment assembly - that is, you can not simply create a physical weld within a part (or sheet metal part).One trick that I have used with imported sheet metal parts (Hoffman enclosures, .Place the sheet metal part into the assembly. More than likely you'll want to . One trick that I have used with imported sheet metal parts (Hoffman enclosures, for example) is to Delete Face w/Heal all the adjacent faces, .

Place the sheet metal part into the assembly. More than likely you'll want to use the "goove" option to fill in the gaps. I would tend to believe that the same option would apply if . Inventor supports various welding types, including fillet welds, groove welds, spot welds, and more. Familiarize yourself with these different weld types and their applications..more.Create Assembly Weldments. Topics in this section. About Strategies for Designing Weldments. Learn when and how to use weld features or cosmetic welds to help with assembly size and . This video is part of a series that was created for the Handout for the Autodesk University class: 323109 Getting you Welders and Designers Connected (20 Tip.

In this video i will show you how to use easily weld command in autodesk inventor 2021For weekly educational videos check out our channel we organised in pla.This tutorial will introduce you to creating Weldment Assemblies in Autodesk Inventor. You will be exposed to creating preparation, fillet welds and groove welds in the 3D environment. How to Add Welding in Inventor. To add welding in Inventor, you can use the following steps: 1. Go to the “Weld” tab in the top menu. 2. Choose the “Fillet” option. 3. Select “Face 1” and “Face 2” as indicated by numbers 1 . I see sheet metal prints where the proper symbol will be used at the location, then have an X located at preferred locations for the actual welds. Chris

1) Multi-body is now supported in sheet metal. Now you can create multiple sheet metal bodies in a single part file. This gives an opportunity for whole new ways of laying out components in Inventor! Create geometry in both solids, then create . Learn inventor sheet metal basic tutorial how to use lofted flange with 2 profile, check it out!!!#sheetmetal #inventor #modeling

Inventor supports various welding types, including fillet welds, groove welds, spot welds, and more. Familiarize yourself with these different weld types and. In this video Pete demonstrates a technique for creating a secondary sheet metal component that follows the contour of another plate part. He'll also share a. In this video i will show you how to use easily weld command in autodesk inventor 2021For weekly educational videos check out our channel we organised in pla. Hello, I am still learning Inventor. How do i close the gap at the corners of a sheet metal box? Inventor 2015. Thank you. Solved: Hello, I am still learning Inventor. How do i close the gap at the corners of a sheet metal box? . Thank you both for your help. i used corner seam and arc weld with a small gap. Reply. Reply. 1 Like 04-12-2017 .

Topics in this section. About Strategies for Designing Weldments Learn when and how to use weld features or cosmetic welds to help with assembly size and performance, drawing automation, and specialized weld state drawing views.; About the Weldments Environment You can create weldment models using a combination of welding-specific and assembly . I haven't done anything for welding in inventor. Solved: I was wondering how to add spot welds to an assembly drawing step by step? I haven't done anything for welding in inventor. . I see sheet metal prints where the proper symbol will be used at the location, then have an X located at preferred locations for the actual welds. Chris. Reply. Inventor Forum > Creating Fill Weld in the Corner of two bends in a sheet metal part; Options. Subscribe to RSS Feed; . Creating Fill Weld in the Corner of two bends in a sheet metal part Anonymous. Not applicable 01-13-2006 12:28 PM. Mark as New; Bookmark; Subscribe; . groove weld is the right one to start with as fillet welds don't .

This video is part of a series that was created for the Handout for the Autodesk University class: 323109 Getting you Welders and Designers Connected (20 Tip. for the weld. First I create a gap and groove weld to close things up and then a fillet weld to reflect what I really want it to look like. "Beerwulf" wrote in message news:[email protected]. Hi Guys, Say, I want to make a simple sheet metal box, (preferably with the top edges In this video Pete will demonstrate a technique for creating an elliptical sheet metal flange, when the Contour Flange tool is unable to do so. This will al.

In our software (SigmaNEST), we are able to create a sketch on the Inventor part file (if sheet metal, the sketch has to be in the Flat Pattern), and give it a particular name. Then in the nesting software, we set it to look for that sketch name for the Marking process, similar to how layers would be used in an AutoCAD-based pattern. But I have the (3) flanges, 2 on the sides and a long one in the back. Then added corner seams between the long and sides to set and equal gap, but this pulls the corner style from the sheet metal defaults. With the hem at a width you have a remnant that is present, so in the sheet metal default the remnant has to be modified.The corner seam will not work on the contoured edge nor will any other sheet metal function such as bend or flange on the edge as seem in the picture. Im not sure why this is such a simple part youd think it would be so easy haha. Even if i solid model it and convert to . Try and keep all your sheet metal sketches on the same plane. Sketch 1 was on the XY plane - make Sketch2 on the XY plane as well. Keep it simple. Test frequently. If you repeat the above steps, when you draw the circle, place a "Point" at the center of the circle. Create the cut feature. Extract the Cut feature as a sheet metal punch iFeature.

12 05 ford expedition power distribution box display

That is partially right. Basically imagine a .25" thick sheet of metal with a 90 degree horizontal bend line at the top to create a 2" flange across the whole thing. Then on that same sheet metal, a vertical bend line at center of sheet, which . To change the corner seam gap, you need to change the seam gap in sheet metal defaults. Click on sheet metal defaults to open, then change Miter/Rip/Seam gap as i have circled in the picture below. Change to the size you need it to be. I have as .1 to get the corner seam as close as it can be. Hope this solves your problem. How to create metal letters, welding and cutting.Hello everyone, today along with the operations of cutting, soldering, you see we perfected this character (.

Can somebody take a look at the picture attached and tell me whats the best way to make tabs on a rolled round ring. I got it done using unfold/refold option but I can not get sheet metal flat. Let me know if there is a good method for . https://www.youtube.com/channel/UCjd_zIvYtQymk0dPx3vTJcA/joinYou Can Support our Channel for more tutorials, We Provide SolidWorks, .

Want all of our free Autodesk Inventor training videos? Visit our Learning Library, which features all of our training courses and tutorials at http://learn.. Hi drew65uk, In the Contour Roll dialog box, change the Unroll Method to Developed Length and then enter the Length you want to end up with.. Then use the Unfold tool (not the Create Flat Pattern tool) to temporarily unfold the part. Then sketch one of your slots, and use the Cut tool to create it. Then use the Rectangular Pattern tool to place the rest of the slots. I'm trying to create an overlapping flange from two adjacet previosly created flanges. The purpose is to create a closed corner to a box and provide for a lap weld rather than edge weld. I can't seem to creat an offset such that the . Learn Autodesk Inventor sheet metal tutorial how to create cone object, check it out!!!Don't forget guys, if you like our videos please "Subscribe", "Like", .

I am still new to inventor (yes only 3 weeks experience ), but with some advice from some folks here I am making headway. I'm still having problems with a few concepts though. After watching a dozen or so videos and reading even more write-ups, I still can't seem to get the proper way to create flanges over curved sheetmetal surfaces. So, after seemingly . Start a new "weldment".. place your sheet metal part into it and do a fillet and cosmetic weld to fill in the gaps.. Something like this.. Inventor 2023 - Dell Precision 5570

inventor welding types

inventor welding modeling

inventor welding instructions

Since no box really exist, any electrical connections (by code) need to be above ground. The reason being, if water gets into a box in or underground, it will trip the circuit constantly and bring in a hazard to the area with live wires. Why do you need a .

how to weld sheet metal in inventor|inventor welding