cnc machining centre programming setup & operation If you are just getting started with CNC, we recommend that you begin with the Machining Center Setup and Operation self-study manual. We use a Key Concepts approach to teaching you about CNC. This proven tutorial method allows us to stress the reasons why things are done as importantly as how they’re done.

So, you have to options to connect the converter box: - if it has RCA output (red/while/yellow), look for cable which will fit "A/V In". This is usually 3.5mm jack like on headphones, with extra.

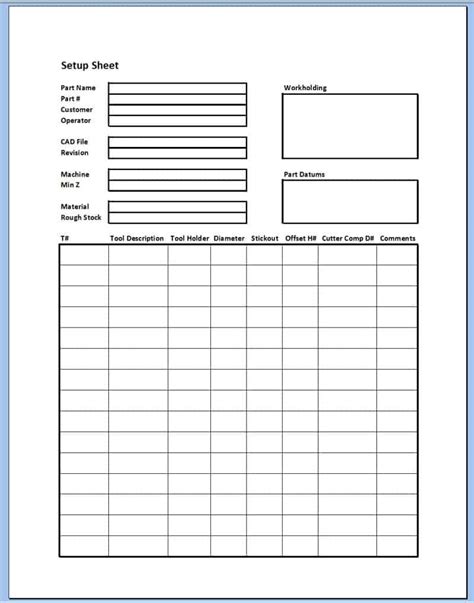

0 · cnc tool set up sheet

1 · cnc machines for dummies

2 · cnc machine setup sheet template

3 · cnc machine setup checklist

4 · cnc machine set up sheet

5 · cnc machine process step by

6 · cnc machine operating instructions

7 · cnc lathe setup sheet

It's probably a sim removal tool. It can be used to pop open the sim tray.In the box with the new iPhone is a small metal paper clip looking items what is it used for?

This is a CNC machining center programming example or Vertical machining centers (VMCs) programming exercise. Basic and easy to understand for . With our method, a set of G10 commands will be automatically and almost instantaneously generated that contain all program zero . By understanding the strengths and applications of each method, CNC programmers can optimize their machining processes and achieve exceptional results. Unlock the art of CNC programming with our beginner .Setup CNC Machining centers 13. Program examples with setting instructions 14. Operations. This course will teach you: - Basics of CNC - CNC machine components and configuration - Programable functions and accessories - Directions of motion (axes) and fundamental geometrical principles - Home position (Reference point) for each axis .

Most experienced programmers will agree that horizontal machining centers are among the most difficult metal-cutting CNC machines to program. The primary reason why horizontals are tough to program is that .If you are just getting started with CNC, we recommend that you begin with the Machining Center Setup and Operation self-study manual. We use a Key Concepts approach to teaching you about CNC. This proven tutorial method allows us to stress the reasons why things are done as importantly as how they’re done.

Setup CNC Machining centers 13. Program examples with setting instructions 14. Operations. This course will teach you: - Basics of CNC - CNC machine components and configuration - Programable functions and accessories - Directions of motion (axes) and fundamental geometrical principles - Home position (Reference point) for each axis . Machining center programming, setup, and operation workbook by Lynch, Michael. Publication date 2013 Topics Machining, Machine-tools -- Numerical control -- Programming Publisher Cary, Ill. : CNC Concepts, Inc. Collection internetarchivebooks; inlibrary; printdisabled Contributor Internet Archive Language English Item Size 139.4M . 1 volume .Buy Machining Center Programming, Setup, and Operation 4th edition (9781492720508) by Mike Lynch for up to 90% off at Textbooks.com. Skip to main content. Ship-Ship-Hooray! Free Shipping on + View Details about Free Shipping . Publisher: CNC Concepts, Inc. Published: 2013

If you want to learn safe, proven, and accepted methods for programming and operating CNC machining centers, you can't afford to miss this Key Concepts approach to learning how to apply CNC machining centers in manufacturing. The content utilizes this unique approach to introduce you to the method of programming and operation that can be applied to . CNC setup is a crucial step in the machining process to ensure the machine, tools, workpiece, and program are in optimal condition for precise machining. The setup process includes initializing and resetting the machine, selecting and setting up tools, installing and positioning the workpiece, importing and verifying the machining program, and .

Vertical machining centers are a vital part of a cnc machine workshop, So here is a Vertical machining center programming example for cnc machinists who have just started learning cnc programming. Vertical Machining Center Programming ExampleFind the best prices on Machining Center Programming, Setup, and Operation, A Guide to Mastering the Use of CNC Machining Centers - Fourth Edition (Paperback) by by Mike Lynch (Author) at BIBLIO | unknown | | Unknown | 9781492720508 Machining Center Programming, Setup, and Operation: A Guide to Mastering the Use of CNC Machining Centers: Lynch, Mike: 9798394489716: Books - Amazon.ca . work for a manufacturing company that uses CNC machining centers or if you are enrolled in a technical school’s CNC curriculum, Machining Center Programming, Setup, and Operation will .

Self Study Manual: FANUC Machining Center Programming, Setup, and OperationWe assume in this text that you understand certain things about basic machining practices – topics that are addressed in the Turning Center Setup and Operation manual. This text can also be used by people that have some shop experience who are not interested in learning about how turning centers are set up or how production runs are completed. Machining Center Programming, Setup, and Operation Workbook: Supplement to Machining Center Programming, Setup, and Operation Manual Paperback – September 25, 2013 by Mike Lynch (Author)

CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write .Get Textbooks on Google Play. Rent and save from the world's largest eBookstore. Read, highlight, and take notes, across web, tablet, and phone.Machining Center Programming, Setup, And Operation. Teach a basic course for the most popular CNC machine type! . Teach how to program a CNC machining center! Turning Center Programming, Setup, And Operation. Just about any metal cutting company has at least one turning center! Why not teach a basic turning center course? CNC Machining Centers are classified THREE types 1.A vertical machining centre (VMC) :-It has its spindle on a vertical axis relative to the work table vertical machining centre is typically used for flat work that requires tool access from top. Milling Centre is a type of vertical machining centre Prepared by: Prof. Rahul Thaker (ACET)

CNC Machining Center Programming, Setup, and Operation 2nd Edition: A Guide to Mastering the Use of CNC Machining Centers (ISBN-13: 9781546946731 and ISBN-10: 154694673X), written by authors Mike Lynch, was published by CreateSpace Independent Publishing Platform in 2017.With an overall rating of 4.5 stars, it's a notable title among other Industrial, .

The primary learning objectives of a CNC & VMC Programming course are to equip students with in-depth understanding and skills related to Computer Numerical Control (CNC) and Vertical Machining Centers (VMC). The course aims to teach how to program, set up, and operate CNC machines and VMCs effectively.Find many great new & used options and get the best deals for CNC Machining Center Programming, Setup, and Operation 2nd Edition : A Guide to Mastering the Use of CNC Machining Centers by Mike Lynch (2017, Trade Paperback) at the best online prices at eBay! Free shipping for many products!

Next, we will delve into the fundamentals of CNC turning center programming. This includes learning the syntax and structure of G-code and M-code, which are the essential languages used to program CNC machines. We will also explore the various modes of operation, such as manual, semi-automatic, and automatic. 3. CNC Turning Center Setup:\ I made a little computer program to save a great deal of time making setup sheets. I think that many people could benefit from it. All you do is open a .NC file and it gives you a setup sheet with all program comments, work offset numbers, tool descriptions, tool numbers, tool offset numbers, and the minimum and maximum X, Y, and Z values found in the program.The CNC double column machining center is also called the gantry machining center, which is the largest CNC machine manufactured by human beings.. Heavy-duty CNC machines designed for handling big and heavy workpieces or molds. These machines feature a bridge-like structure with two columns that support the spindle head, which moves along the X and Y axes, while the .

cnc tool set up sheet

Engaging with these questions can enhance your understanding and application of CNC programming. Key Components of CNC Machining Centers. CNC machining centers are intricate systems where each component plays a crucial role in ensuring precision, efficiency, and versatility in machining operations.CNC Machining Center Programming, Setup, and Operation 2nd Edition: A Guide to Mastering the Use of CNC Machining Centers by Lynch, Mike - ISBN 10: 154694673X - ISBN 13: 9781546946731 - CreateSpace Independent Publishing Platform - 2017 - Softcover Essential G-Code Commands. In CNC programming, essential G-codes streamline complex movements into straightforward instructions. For instance: G00 (Rapid Positioning): Moves the tool quickly to a specific point without cutting, ideal for fast repositioning. G01 (Linear Interpolation): Directs the tool to cut in a straight line at a set feed rate. G02/G03 (Circular .

kci metal fabrication

k-1 box 19 distributions

Gaskets help to seal electrical enclosures according to the requirements of the National Electrical Manufacturer’s Association (NEMA): Ratings are numbered from 1 to 12. Most common ratings for indoor applications are 12 and 13 while 3, 4, 4x, 6, and 6P are most common for outdoor applications.

cnc machining centre programming setup & operation|cnc machine process step by