box-shaped concrete or metal culvert Concrete box culverts are typically used where the streambed is earth or granular soil and rock is not close enough to the streambed to directly support the structure. Three-sided concrete . Galvanized steel is a form of standard steel in which the steel is coated in zinc to ensure enhanced corrosion resistance. This galvanized coating protects the steel substrate from damage typically caused by moisture or temperature changes.

0 · concrete culvert sizes and prices

1 · concrete box culverts price list

2 · concrete box culverts near me

3 · concrete box culvert weight chart

4 · concrete box culvert sizes chart

5 · concrete box culvert cost sheet

6 · concrete box culvert cost estimator

7 · box culvert catalogue

Constructed from stainless steel or cast iron, this compact container holds wood chips or pellets and is placed directly on your grill’s burners or grates. As the grill heats up, the wood inside the smoker box begins to .

Why Precast Box Culverts? •Advantages or precast concrete for box culverts •Flexible sizes with spans up to 20’ •Superior hydraulics •Accelerated construction •Quality of fabrication, structural integrity, and durability •NPCA Certified Plants Demand for Precast Box Culverts •Significant .

• Box culverts can be made in large sizes to accommodate increased flow rates and .

Shape: Common shapes include circular, box, elliptical, and arch culverts. Shape impacts water flow dynamics. Material: Concrete, corrugated metal, and plastic are common. Material affects strength, durability, and .Concrete box culverts are typically used where the streambed is earth or granular soil and rock is not close enough to the streambed to directly support the structure. Three-sided concrete .Precast concrete culvert are box shaped configurations used for transportation infrastructure, stormwater management, and multiple other applications. Engineers and contractors use our culvert products for everything from .

Culverts are typically constructed using durable concrete, steel, or plastic materials. They come in various shapes and sizes, depending on the specific requirements of the site and the volume of water that needs to be conveyed. . Typical box culverts are designed in accordance with ASTM C-1433 and consist of 5,000 PSI concrete with Type I/II cement. Box culverts as a structural element function effectively as strong and durable bridges.• Box culverts can be made in large sizes to accommodate increased flow rates and capacities. • Boxes can be set with 0 feet to 100 feet of cover. Cast-In-Place Concrete Box Culverts. Box culverts that are made of reinforced concrete and fabricated in the field are considered cast-in-place. These structures are built with concrete and rebar at the project site. Forms are .

concrete culvert sizes and prices

The foundation is laid using reinforced concrete, providing a sturdy base. Formwork is assembled to shape the culvert’s structure, requiring skilled craftsmanship to .Box culverts, specifically, are four-sided concrete culvers made from precast or cast-in-place concrete in the shape of a box. Box Culverts are used for drainage purposes by controlling the .Why Precast Box Culverts? •Advantages or precast concrete for box culverts •Flexible sizes with spans up to 20’ •Superior hydraulics •Accelerated construction •Quality of fabrication, structural integrity, and durability •NPCA Certified Plants Demand for Precast Box Culverts •Significant increase in recent years due to:

concrete box culverts price list

Shape: Common shapes include circular, box, elliptical, and arch culverts. Shape impacts water flow dynamics. Material: Concrete, corrugated metal, and plastic are common. Material affects strength, durability, and corrosion resistance.Concrete box culverts are typically used where the streambed is earth or granular soil and rock is not close enough to the streambed to directly support the structure. Three-sided concrete culverts may be rectangular in shape or a frame with varying wall and slab thickness or an arched or arch-topped structure.

Precast concrete culvert are box shaped configurations used for transportation infrastructure, stormwater management, and multiple other applications. Engineers and contractors use our culvert products for everything from bridges and streambeds to underground storage and .Culverts are typically constructed using durable concrete, steel, or plastic materials. They come in various shapes and sizes, depending on the specific requirements of the site and the volume of water that needs to be conveyed. Common culvert shapes include round, box, elliptical, and .

Typical box culverts are designed in accordance with ASTM C-1433 and consist of 5,000 PSI concrete with Type I/II cement. Box culverts as a structural element function effectively as strong and durable bridges.• Box culverts can be made in large sizes to accommodate increased flow rates and capacities. • Boxes can be set with 0 feet to 100 feet of cover. Cast-In-Place Concrete Box Culverts. Box culverts that are made of reinforced concrete and fabricated in the field are considered cast-in-place. These structures are built with concrete and rebar at the project site. Forms are constructed to outline and create the dimensions and shape of the box culvert, and concrete is poured into them.

The foundation is laid using reinforced concrete, providing a sturdy base. Formwork is assembled to shape the culvert’s structure, requiring skilled craftsmanship to ensure accuracy and robustness. High-quality formwork materials, such as steel or engineered wood, impact the final outcome.Box culverts, specifically, are four-sided concrete culvers made from precast or cast-in-place concrete in the shape of a box. Box Culverts are used for drainage purposes by controlling the intake and outtake of water.Why Precast Box Culverts? •Advantages or precast concrete for box culverts •Flexible sizes with spans up to 20’ •Superior hydraulics •Accelerated construction •Quality of fabrication, structural integrity, and durability •NPCA Certified Plants Demand for Precast Box Culverts •Significant increase in recent years due to:

Shape: Common shapes include circular, box, elliptical, and arch culverts. Shape impacts water flow dynamics. Material: Concrete, corrugated metal, and plastic are common. Material affects strength, durability, and corrosion resistance.Concrete box culverts are typically used where the streambed is earth or granular soil and rock is not close enough to the streambed to directly support the structure. Three-sided concrete culverts may be rectangular in shape or a frame with varying wall and slab thickness or an arched or arch-topped structure.Precast concrete culvert are box shaped configurations used for transportation infrastructure, stormwater management, and multiple other applications. Engineers and contractors use our culvert products for everything from bridges and streambeds to underground storage and .

double cut sheet metal shears

Culverts are typically constructed using durable concrete, steel, or plastic materials. They come in various shapes and sizes, depending on the specific requirements of the site and the volume of water that needs to be conveyed. Common culvert shapes include round, box, elliptical, and .

Typical box culverts are designed in accordance with ASTM C-1433 and consist of 5,000 PSI concrete with Type I/II cement. Box culverts as a structural element function effectively as strong and durable bridges.• Box culverts can be made in large sizes to accommodate increased flow rates and capacities. • Boxes can be set with 0 feet to 100 feet of cover. Cast-In-Place Concrete Box Culverts. Box culverts that are made of reinforced concrete and fabricated in the field are considered cast-in-place. These structures are built with concrete and rebar at the project site. Forms are constructed to outline and create the dimensions and shape of the box culvert, and concrete is poured into them.

The foundation is laid using reinforced concrete, providing a sturdy base. Formwork is assembled to shape the culvert’s structure, requiring skilled craftsmanship to ensure accuracy and robustness. High-quality formwork materials, such as steel or engineered wood, impact the final outcome.

concrete box culverts near me

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel.

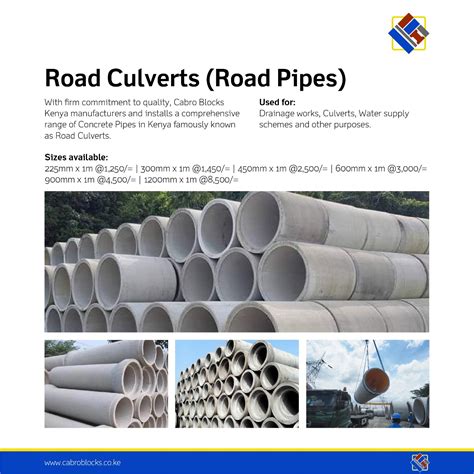

box-shaped concrete or metal culvert|concrete box culvert cost sheet