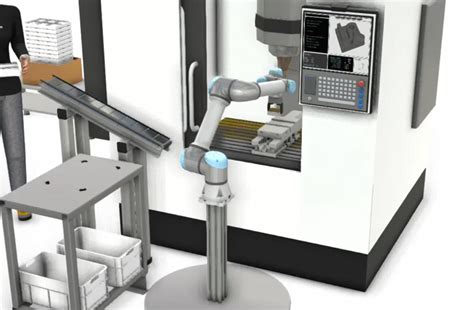

cnc machine tending robot Automate CNC machine tending with Vention's solutions. Increase productivity by automating loading and unloading of parts in CNCs and more. Platform. Software . Robotic machine tending was introduced to boost ROI, enhance production .

$34.40

0 · universal robots machine tending

1 · universal robot tending cnc machine

2 · robotic arm cnc milling

3 · kuka milling robot price

4 · kuka cnc milling robot

5 · ceiling mounted robotic arm

6 · automatic loading and unloading robot

7 · automated cnc holster milling machine

Toledo Metal Spinning Company has designed and built the necessary tooling to manufacture several different sizes of metal domes offering various metal thicknesses and metal types. TMS utilitizes a unique one-piece flow manufacturing process to produce metal domes with very little throughput time and extremely high quality.

universal robots machine tending

Collaborative robots (cobots) are automation tools that can perform machine tending tasks and work alongside operators, helping fill persistent labor shortages while offering high-quality, .Using the Machine Tending Copilot algorithm, the robot finds the optimal .

universal robot tending cnc machine

Solutions for Robotic Machining and Machine Tending Robots. FANUC has a wide range of robots for manufacturing CNC machines to automate a variety of processes, including: .

Automate machine tending with robots to significantly enhance your production by providing superior accuracy and continuous operation, unlike manual tending. Increase efficiency, .

A CNC machine tending robot is an automated system designed to load and unload parts from a CNC (Computer Numerical Control) machine, such as a milling machine, lathe, or .

Automate CNC machine tending with Vention's solutions. Increase productivity by automating loading and unloading of parts in CNCs and more. Platform. Software . Robotic machine tending was introduced to boost ROI, enhance production .

Contact North America. HALTER CNC Robotics LLC 21995 Fillmore Road Cascade, Iowa 52033 United States T: 800 314 8261 [email protected] VAT ID: US473961908THE BENEFITS OF CNC INTEGRATION Lights Out Production: OB7 CNC machine robot arm is a cost-effective and easy-to-set-up solution that provides the fastest ROI of any other cobot on the market. By ensuring that spindles .

While other, more complex solutions, involved deploying CNC machine tending robotic systems on gantry rails to service multiple machines. From CNCs to CMMs , Washing Systems , auto loaders, and or Laser Marking Systems , we can offer a wide range of CNC machine tending robots and equipment solutions to meet your specific needs

robotic arm cnc milling

Productive Robotics' OB7 CNC packages come all-in-one for immediate automation. Just roll it up to your machine and press go. OB7 collaborative robots work just like a human operator to load parts for manufacturing and unload finished parts. Key benefits of OB7 Collaborative Robot CNC Packages: Fast and simple installation - as little as a few .The Machine Tending Solution is the only solution you need to automate your CNC machines. Combined with our worldwide distribution network, you can automate a CNC machine in hours instead of weeks. . Using the Machine Tending Copilot algorithm, the robot finds the optimal path from point A to point B without colliding with the environment .Top CNC Milling robot manufacturers FANUC. FANUC, headquartered in Japan, is one of the largest manufacturers of Industrial robots, including those for CNC Milling applications.They offer a wide range of articulated arm and SCARA robots with different payload capacities, reaches, and mounting options to suit any machine shop's needs. Their robots are very reliable, fast, and . Machine tending robots are versatile and can handle various tasks, including loading and unloading parts in CNC machines, lathes, brake presses, and injection mold machines. They can also perform secondary tasks such as quality checks, cleaning, and finishing operations, enhancing overall production efficiency.

Robotic CNC machine tending also automates the process, but offers more flexibility. Robots can handle variable parts and be quickly adapted to any changes in production. You can program a robot for pre- or post-machining tasks and reprogram it whenever a need arises. Robots are significantly better suited for dynamic or high-mix low-volume .Moreover, it enables the setup of a new batch during the robot's operation, thereby enhancing overall productivity. TURNSTACKER. . Experience the Future of CNC Machine Tending with HALTER LoadAssistants. Boost Your Efficiency. HALTER offers a highly mobile and user-friendly solution, with easily movable robot cells and quick calibration . A CNC machine tending robot is an automated system designed to load and unload parts from a CNC (Computer Numerical Control) machine, such as a milling machine, lathe, or grinding machine. These robots are typically used in manufacturing settings to increase efficiency, reduce labor costs, and improve safety.

Caron Engineering MiConnect software to sequence the operation and control the CNC and Cobot; Lang fan for chip clearing; Here is a link to the video. . Generally machine tending robots have such little motion time compared to the machining operations that they last a long time. The biggest issues I have seen are from coolant contamination in .

In CNC robotic machine tending, risks can stem from the robot’s movements, the CNC machine’s operation, or both, which may pose risks of entrapment, collision, pinch points, or other dangerous situations. Safety measures are crucial to mitigate these hazards and ensure safe operation and can include emergency stops, interlocked barriers .

Manufacturer of Pick And Place Robots - CNC Machine Tending Robot, Aluminum Die Casting Pick & Place Robots, Light Glowing Hydraulic Press Pick & Place Robotic engine and Pick & Place Robots Automation offered by Arrowtek Robotic Private Limited, Chennai, Tamil Nadu.Our machine tending robots connect to any brand of cnc machine. Give us a call today to get started implementing robotic machine tending in your production. “Every time we’ve reached out, we got a real person to respond to us .Having trouble finding qualified machine operators? Adding a simple robot to a 2 or 3 machine cell of new or existing CNC lathes or mills is the most common and most economical way to solve this problem.CNC MACHINE TENDING ROBOTS Robotic CNC Machine tending is a great solution when considering the benefits of contract machining and lean manufacturing. From placing raw parts into machines with or without the help .

#cncmachine #robotAutonomous mobile robots can be integrated with stationary industrial robots when tending to machines in order to improve the flexibility, efficiency and productivity of the overall system. . Material or a ready-made blank is taken and inserted into the CNC machine, for example a grinding, milling or turning machine. Once machining has been .

CNC machine tending robot. Two machining process in one cycle. With automation quality control solution. UNiBOT iR Series is manufacture in Thailand by UNICA.Eliminate the complexity of deploying CNC machine tending applications and see results fast. With D:PLOY CNC, your complete machine tending application can be deployed in just hours. . PLOY CNC works with many leading collaborative or light industrial robot arms and any CNC milling or lathe machine. At least 80% initial deployment time .What is a CNC robot? Computer Numerical Control robots (or CNC robots) are incredibly smart machines used in manufacturing and other industries to make things quickly and precisely.. Generally, these Industrial robots use technology for automated machining, much like CNC machines.However, these robots take standard CNC technology one step further. They can . How to find the real cost of a machine tending solution. Here's how to get a clear cost of machine tending automation using the 3 different types: Bespoke machine tending solution. With bespoke solutions, the robot integrator will need to calculate the cost of automating your CNC machine for you.

marine watertight junction box

Finding qualified skilled labor for your CNC Machining operation is more difficult than ever. A robotic machine tool tending system can help maximize machine utilization and lower costs. Most importantly, a robotic machine tending system from KC Robotics will help you realize the Return on Investment (ROI) you need to succeed. +

The robotic automation systems as a whole is an attempt to reduce the involvement of humans in the production process, and the most efficient way to ensure that injuries on the working floor are reduced almost entirely is the use of robot machine tending. When the process of feeding materials into a machine is delegated to a robot instead of a human being, the probabilities of . Guide to machine tending with robots . For manufacturing businesses, automation is becoming an essential part of remaining competitive in a rapidly changing commercial landscape. . a UR10e is responsible for feeding a CNC machine. The robot supports the company in utilizing its machines to full capacity by taking over the night shift .

Especially good for CNC machine tending and quality inspection. CNC machines automation by robot cells . Businesses in the machining industry are more and more often using automation of CNC machining services. It is supported by almost any kind of CNC machines, such as lathes, milling machines, and plasma cutting machines, and made in order to .

kuka milling robot price

kuka cnc milling robot

ceiling mounted robotic arm

Remp, Looks like the zone you have is a strong caididate for fixing a Parallel Fan Powered VAV box.When the VAV box turns down to its minimum position,the fan comes on as the stage 1 reheat.It draws the warm air from the ceiling plenum and pumps it back to the space.If that is insufficient,the terminal reheater comes on as stage 2 reheat.

cnc machine tending robot|kuka cnc milling robot