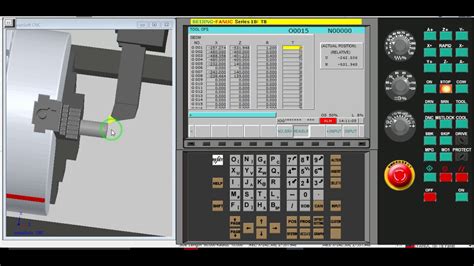

cnc machine part programming pdf To make a part on a CNC machine, you tell it how to make the part using a G-Code . Since 1980, West Lincoln Sheet Metal has offered HVAC installation services (ventilation/duct work, furnaces and air conditioners) for area residents, as well as multiple new construction projects throughout the area.

0 · manual programming cnc

1 · manual cnc programming for beginners

2 · how to write cnc code

3 · cnc programming for beginners PDF

4 · cnc programming examples

5 · cnc machine tool programming

6 · cnc lathe programming for beginners

7 · basic cnc programming for beginners

The following are the main welding processes used for Sheet Metal welding: Stick Welding or SMAW; Gas Tungsten Arc Welding (GTAW or TIG)

Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.To make a part on a CNC machine, you tell it how to make the part using a G-Code .The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming . Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.

The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming examples are used to explain the commands and statements, which are also defined according to DIN 66025. 2. Work preparationTo machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. Programming with this type of coordinates implies the use of a "part zero" as a coordinate origin.

Numerical control (NC) enables an operator to communicate with machine tools through a series of numbers and symbols. NC which quickly became Computer Numerical Control (CNC) has brought tremendous changes to the metalworking industry.Here are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC Programming Software, G-Wizard Editor. Looking to learn CNC G-Code? Need a quick and easy G-Code Tutorial or G-Code Course? Want some easy G-Code Training?

white metal chimney box

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.

This programming workbook provides basic principles necessary to program the Haas lathe. It is not intended as an in-depth study of all ranges of the machine use.table of contents 1 - numerical control 1 definition of numerical control . . . 1 nc and cnc technology ... 1 conventional and cnc machining. . . 2All CNC machining begins with a part program, a sequential instructions or coded commands that direct the specific machine functions. Part program may be manually generated or, using computer aided part programming systems.

Generate a part program using the software “Walli” for the part shown in Figure 3 for the Cybermill CNC milling machine. Once program is completed, simulate the program for

Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming examples are used to explain the commands and statements, which are also defined according to DIN 66025. 2. Work preparationTo machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. Programming with this type of coordinates implies the use of a "part zero" as a coordinate origin.

Numerical control (NC) enables an operator to communicate with machine tools through a series of numbers and symbols. NC which quickly became Computer Numerical Control (CNC) has brought tremendous changes to the metalworking industry.Here are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC Programming Software, G-Wizard Editor. Looking to learn CNC G-Code? Need a quick and easy G-Code Tutorial or G-Code Course? Want some easy G-Code Training?G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.

This programming workbook provides basic principles necessary to program the Haas lathe. It is not intended as an in-depth study of all ranges of the machine use.

table of contents 1 - numerical control 1 definition of numerical control . . . 1 nc and cnc technology ... 1 conventional and cnc machining. . . 2All CNC machining begins with a part program, a sequential instructions or coded commands that direct the specific machine functions. Part program may be manually generated or, using computer aided part programming systems.

manual programming cnc

white steel and glass apothecary cabinet

manual cnc programming for beginners

how to write cnc code

$75.00

cnc machine part programming pdf|cnc machine tool programming