bending sheet metal box with outside flanges One of the more common questions asked in day-to-day press brake operations is "Can I form a box that deep?" If you select the wrong tool, . Sheet metal screws are typically #2 to #14 in diameter, with some head designs available in 5/16″ and 3/8″. Typical lengths range from 3/16″ to 3 1/2″. All other sheet metal screw head styles (hex, pan, round, and truss) are measured from under the head to the screw’s tip.

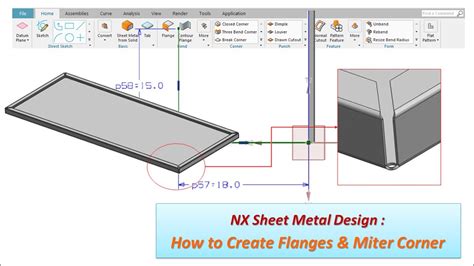

0 · sheet metal corner flange design

1 · sheet metal bending size chart

2 · sheet metal bending problems

3 · sheet metal bending methods

4 · sheet metal bending machine

5 · sheet metal bending directions

6 · partial bending sheet metal

7 · folding sheet metal flange

What Is a Wood CNC Machine? A wood CNC machine is a type of computer-controlled tool that can cut and shape wood with high precision. Think of it like a 3D printer, but for woodworking. Instead of extruding plastic, a wood CNC machine uses a router bit or cutting tool that spins at high speeds to carve away wood in a specified pattern or design.

Learn essential custom sheet metal bending techniques and tips for designing and producing high-quality metal parts. Discover best practices, design guidelines, and practical advice for . One of the more common questions asked in day-to-day press brake operations is "Can I form a box that deep?" If you select the wrong tool, .

Learn the laser cut sheet metal bending guidelines for SendCutSend. Find tips, specifications and requirements for your custom sheet metal bending needs. Deep-box bending is not a complicated process, but managing it properly requires a lot of forethought with respect to your choice of press brake and tooling. Think carefully about the type of work you are planning to do on a .In this article, we will discuss sheet metal design guidelines considering a press bending machine. You should consider the following points during the design of sheet metal parts for press bending. Sheetmetal is available in standard . More Than One Sheet Metal Bending Formula. Press brake technicians can use various formulas to calculate bend functions. For instance, in this article we have used the following for outside setback: OSSB = [Tangent .

How to apply our overall part size, bend length, and flange length dimensions when measuring your design. The best way to figure out the minimum flange length that you can have is to go to your chosen material’s page on our .Learn essential custom sheet metal bending techniques and tips for designing and producing high-quality metal parts. Discover best practices, design guidelines, and practical advice for successful sheet metal bending. . Inside edge of bend to hems outside edge = 5t + Hem radius; Flange and Chamfer Design. A flange is an edge that sticks out . We offer a few bending equipment details that might not be familiar to those outside the fab shop: Some sheet metal designs can be built only with a folding machine. Many sheet metal designs can be bent only with a press brake.

One of the more common questions asked in day-to-day press brake operations is "Can I form a box that deep?" If you select the wrong tool, the side of the box will crash into the ram. This can produce the wrong bend angle or prevent the forming of tight corners. Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.Learn the laser cut sheet metal bending guidelines for SendCutSend. Find tips, specifications and requirements for your custom sheet metal bending needs. Deep-box bending is not a complicated process, but managing it properly requires a lot of forethought with respect to your choice of press brake and tooling. Think carefully about the type of work you are planning to do on a press brake before you make that purchase.

In this article, we will discuss sheet metal design guidelines considering a press bending machine. You should consider the following points during the design of sheet metal parts for press bending. Sheetmetal is available in standard thickness. Manufacturer provides sheets thickness in gauge. More Than One Sheet Metal Bending Formula. Press brake technicians can use various formulas to calculate bend functions. For instance, in this article we have used the following for outside setback: OSSB = [Tangent (degree of .

How to apply our overall part size, bend length, and flange length dimensions when measuring your design. The best way to figure out the minimum flange length that you can have is to go to your chosen material’s page on our website and look at the design guidelines for that material and thickness.Box bending can be rather tricky with sheet metal because of the geometry of a press brake. typically the upper beam or punch holder will get in the way of very deep boxes. When bending with large returns there are a few tricks outside of just tooling selection.Learn essential custom sheet metal bending techniques and tips for designing and producing high-quality metal parts. Discover best practices, design guidelines, and practical advice for successful sheet metal bending. . Inside edge of bend to hems outside edge = 5t + Hem radius; Flange and Chamfer Design. A flange is an edge that sticks out . We offer a few bending equipment details that might not be familiar to those outside the fab shop: Some sheet metal designs can be built only with a folding machine. Many sheet metal designs can be bent only with a press brake.

One of the more common questions asked in day-to-day press brake operations is "Can I form a box that deep?" If you select the wrong tool, the side of the box will crash into the ram. This can produce the wrong bend angle or prevent the forming of tight corners. Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.Learn the laser cut sheet metal bending guidelines for SendCutSend. Find tips, specifications and requirements for your custom sheet metal bending needs.

metal precision casting with cnc machining

Deep-box bending is not a complicated process, but managing it properly requires a lot of forethought with respect to your choice of press brake and tooling. Think carefully about the type of work you are planning to do on a press brake before you make that purchase.

sheet metal corner flange design

In this article, we will discuss sheet metal design guidelines considering a press bending machine. You should consider the following points during the design of sheet metal parts for press bending. Sheetmetal is available in standard thickness. Manufacturer provides sheets thickness in gauge.

More Than One Sheet Metal Bending Formula. Press brake technicians can use various formulas to calculate bend functions. For instance, in this article we have used the following for outside setback: OSSB = [Tangent (degree of . How to apply our overall part size, bend length, and flange length dimensions when measuring your design. The best way to figure out the minimum flange length that you can have is to go to your chosen material’s page on our website and look at the design guidelines for that material and thickness.

metal purple martin house

sheet metal bending size chart

Electricity Saving Box is advertised as a revolutionary device that can significantly reduce your home’s electricity usage simply by plugging it into a wall outlet. The makers claim it “stabilizes electrical current” and corrects energy waste, slashing utility bills by 40% or more.

bending sheet metal box with outside flanges|partial bending sheet metal