disadvantages of cnc machine Weighing these disadvantages against the positive aspects of using CNC machines will give you the information you need to make the most informed decision for manufacturing your made-to-order parts. 1. The grinding machine HELITRONIC RAPTOR is the ideal entry-level machine for efficient grinding and regrinding of rotationally symmetrical tools with a small footprint. The machine grinds tools with diameters of 3 to 320 mm, a tool length including End Face Operation up to 280 mm and weight up to 50 kg.

0 · pros and cons of machining

1 · disadvantages of cnc milling

2 · cnc punching machine disadvantages

3 · cnc milling pros and cons

4 · cnc milling advantages and disadvantages

5 · cnc machining advantages and disadvantages

6 · cnc machine pros and cons

7 · advantages of cnc milling machine

WE START WITH RAW MATERIALS AND FINISH WITH IMPROVING YOUR BOTTOM LINE. A purchasing power of over five million pounds of steel each year gives Washington Metal Fabricators the advantages of daily deliveries, low-cost raw materials, and negotiated contracts with steel distributors.

Weighing these disadvantages against the positive aspects of using CNC machines will give you the information you need to make the most informed decision for manufacturing your made-to-order parts. 1.

1) Accuracy: The accuracy of CNC machines can be up to 10 times better than manual cutting, especially the 5-axis cnc machine is the option for high-end precision machining projects. 2) Speed: It is much faster than manual cutting.

pros and cons of machining

disadvantages of cnc milling

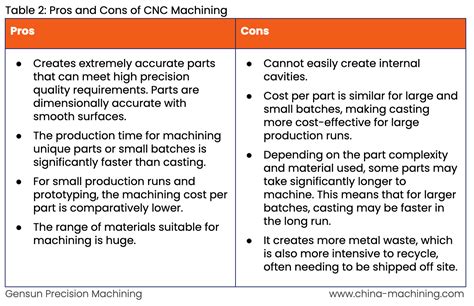

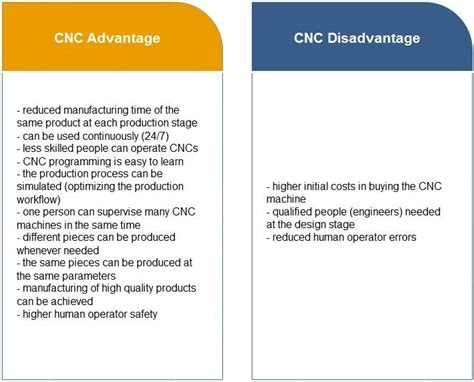

What are the main disadvantages of CNC machining? The main disadvantages of CNC machining are high initial costs, the requirement for skilled labour, material limitations, inefficiency for small production runs, and complex . Advantages of CNC Machines: They offer high precision and consistency, increased production speed, reduced labor costs, and the ability to automate complex . CNC machines have revolutionized manufacturing by improving machining quality and production speed to keep up with the ever-growing demand for complex machine parts. These machines offer various advantages over .Disadvantages. Cost: CNC machines are more expensive and require a greater initial investment than machines that can be operated manually. However, as this technology becomes the standard, supply is increasing resulting in costs .

However, CNC machining also has drawbacks, such as high initial costs, maintenance requirements, and the need for skilled programmers. Despite these challenges, . One of the main disadvantages of using CNC machines is the high upfront cost. CNC machines are technologically advanced and require specialized training, maintenance, . Disadvantages of CNC Milling. While CNC milling offers numerous advantages, it also has some disadvantages that need to be considered in specific manufacturing scenarios. Some of the key disadvantages of CNC .In this article, we'll explore the key advantages and disadvantages of CNC machining. By examining both sides, you can make an informed decision about incorporating this powerful .

Weighing these disadvantages against the positive aspects of using CNC machines will give you the information you need to make the most informed decision for manufacturing your made-to-order parts. 1.1) Accuracy: The accuracy of CNC machines can be up to 10 times better than manual cutting, especially the 5-axis cnc machine is the option for high-end precision machining projects. 2) Speed: It is much faster than manual cutting. What are the main disadvantages of CNC machining? The main disadvantages of CNC machining are high initial costs, the requirement for skilled labour, material limitations, inefficiency for small production runs, and complex maintenance needs.

Advantages of CNC Machines: They offer high precision and consistency, increased production speed, reduced labor costs, and the ability to automate complex processes. Disadvantages of CNC Machines: They require a high initial investment cost, need skilled operators for programming, and can be complex to maintain. CNC machines have revolutionized manufacturing by improving machining quality and production speed to keep up with the ever-growing demand for complex machine parts. These machines offer various advantages over traditional machining tools. However, there are some disadvantages as well to CNC Machining. So, what are the benefits of CNC Machining?Disadvantages. Cost: CNC machines are more expensive and require a greater initial investment than machines that can be operated manually. However, as this technology becomes the standard, supply is increasing resulting in costs gradually decreasing. Skills Loss: As the demand for manual machine operators decreases, fewer and fewer new students .

However, CNC machining also has drawbacks, such as high initial costs, maintenance requirements, and the need for skilled programmers. Despite these challenges, the benefits of CNC machining often outweigh the disadvantages, providing significant value in modern manufacturing. One of the main disadvantages of using CNC machines is the high upfront cost. CNC machines are technologically advanced and require specialized training, maintenance, and software updates, all of which contribute to their initial expense. Disadvantages of CNC Milling. While CNC milling offers numerous advantages, it also has some disadvantages that need to be considered in specific manufacturing scenarios. Some of the key disadvantages of CNC milling include: Material WastageIn this article, we'll explore the key advantages and disadvantages of CNC machining. By examining both sides, you can make an informed decision about incorporating this powerful technique into your production process.

cnc punching machine disadvantages

Weighing these disadvantages against the positive aspects of using CNC machines will give you the information you need to make the most informed decision for manufacturing your made-to-order parts. 1.1) Accuracy: The accuracy of CNC machines can be up to 10 times better than manual cutting, especially the 5-axis cnc machine is the option for high-end precision machining projects. 2) Speed: It is much faster than manual cutting. What are the main disadvantages of CNC machining? The main disadvantages of CNC machining are high initial costs, the requirement for skilled labour, material limitations, inefficiency for small production runs, and complex maintenance needs. Advantages of CNC Machines: They offer high precision and consistency, increased production speed, reduced labor costs, and the ability to automate complex processes. Disadvantages of CNC Machines: They require a high initial investment cost, need skilled operators for programming, and can be complex to maintain.

CNC machines have revolutionized manufacturing by improving machining quality and production speed to keep up with the ever-growing demand for complex machine parts. These machines offer various advantages over traditional machining tools. However, there are some disadvantages as well to CNC Machining. So, what are the benefits of CNC Machining?Disadvantages. Cost: CNC machines are more expensive and require a greater initial investment than machines that can be operated manually. However, as this technology becomes the standard, supply is increasing resulting in costs gradually decreasing. Skills Loss: As the demand for manual machine operators decreases, fewer and fewer new students .

However, CNC machining also has drawbacks, such as high initial costs, maintenance requirements, and the need for skilled programmers. Despite these challenges, the benefits of CNC machining often outweigh the disadvantages, providing significant value in modern manufacturing.

One of the main disadvantages of using CNC machines is the high upfront cost. CNC machines are technologically advanced and require specialized training, maintenance, and software updates, all of which contribute to their initial expense. Disadvantages of CNC Milling. While CNC milling offers numerous advantages, it also has some disadvantages that need to be considered in specific manufacturing scenarios. Some of the key disadvantages of CNC milling include: Material Wastage

cnc milling pros and cons

cnc milling advantages and disadvantages

cnc machining advantages and disadvantages

cnc machine pros and cons

$69.99

disadvantages of cnc machine|disadvantages of cnc milling