sheet metal die design pdf Die design handbook: a practical reference book on process analysis, product design, metal movements, materials, and proved die designs . Find the perfect u shaped bracket stock photo, image, vector, illustration or 360 image. Available for both RF and RM licensing.

0 · tool and die design pdf

1 · sheet metal stamping process pdf

2 · sheet metal punching die

3 · sheet metal operations pdf

4 · sheet metal design calculations pdf

5 · sheet metal bending pdf

6 · die and punch assembly

7 · curling operation in sheet metal

$104.93

Die design handbook: a practical reference book on process analysis, product design, metal movements, materials, and proved die designs .

Chapter 4 Die Design - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online.Handbook Of Die Design S Ben Porath Sheet-Metal Stamping and Bending - mheducation.com Several computer-aided design tools for designing dies for parts to be . Handbook Of Die Design (PDF) - metabase.stukent.com Handbook of Die Design Ivana Suchy,2006 This classic handbook provides the major formulas, calculations, cost estimating techniques .

PDF | This paper proposed a novel methodology for designing and manufacturing of sheet metal dies based on features of sheet parts. . AUTOMATION OF SHEET METAL COMBINATION DIE DESIGN PROCESS .Sheet Metal Stamping Stamping presses and stamping dies are tools used to produce high volume sheet metal parts. The press provides the force to close the stamping dies where they shape and cut the sheet metal into finished parts. Production stamping is generally performed using sheet metal materials .020” to .080” thick, but the process

Written by an engineer with decades of practical manufacturing experience, this new edition has been thoroughly revised and is a complete modern guide to sheet metal forming processes and die design – still the most commonly used methodology for the mass-production manufacture of aircraft, automobiles, and complex high-precision parts. Boljanovic V. Sheet Metal Forming Processes and Die Design. pdf file size 27,31 MB; added by Silver. 03/17/2014 22:17; info modified 08/13/2020 13:31; . 0831131829. By an engineer with decades of practical manufacturing experience, this book is a complete modern guide to sheet metal forming processes and die design - still the most commonly . This book provides a guide to sheet metal forming processes and die design. It covers the fundamentals of sheet metal forming operations such as shearing, blanking, punching, bending, deep drawing and stretching.This paper highlights the development of a 2.6mm thin sheet metal mounting bracket with Hole Extrusion process using finite element analysis to identify the problem areas through software, simulation results and prepare the query report and suggest modifications in the product design.

SHEET METAL FORMING PROCESSES AND DIE DESIGN Second Edition VUKOTA BOLJANOVIC, Ph.D. Industrial Press SMSD_00.indd iii 15/01/14 9:28 AM. A full catalog record for this book is available from the Library of Congress. ISBN 978-0-8311-3492-1 Industrial Press, Inc. 32 Haviland Street, Unit 2C

Design & Analysis of Sheet Metal Die For Deep Drawing Operations 1Mr. Nilesh N Sawalkar, 2Prof. Fahim Shaikh 1PG Student (ME CAD/CAM),Buldana, Maharashtra, India. 2Department of Mechanical Engineering, PLITMS Buldana, Maharashtra, India. Abstract - The process in which a punch forces a flat sheet metal blank into a die cavity is known as deep .Sheet Metal Die Design - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document discusses sheet metal die design and provides links to information on types of dies and sheet metal forming. The types of dies link leads to a page explaining the main categories of dies used in metalworking like blanking, piercing, bending, and drawing dies.DIE DESIGN It is the intention of this part to present as complete a picture as space will permit of the knowledge and skills needed for the effective design of dies for sheet metal forming. The text is presented in six chapters, with detailed discussions of die design for each of the manufacturing processes covered in Part 11.

Master metal stamping and die design with this ultimate guide. Get expert tips and insights to improve your manufacturing processes. Start learning now. . Metal sheet specifications: steel strip, steel plate, slit steel strip, etc. Size range of steel plates and strips (GB/T708-2006)

In this study, an effective and efficient design strategy is proposed to design sheet-metal die in order to reduce stress 722 I. Demir et al. / Materials and Design 29 (2008) 721–727 and increase fatigue life of sheet-metal die. Download full-text PDF Read full-text. Download full-text PDF. Read full-text. Download citation. Copy link Link copied. . tool in the sheet metal die design, reducing ti me and trial .The document outlines General Motor's standards for progressive die design. It includes an index of design topics covered, such as die construction, pad design, stock lifters, and panel accumulation. Safety items are highlighted, such as .Sheet Metal Stamping Dies Die Design and Die-Making Practice. by Vukota Boljanovic. 224 Pages, 6.00 x 9.00 x 0.60 in. Paperback; ISBN: 9780831134631; Availability: Print On Demand; Publication Date: July 2012; .95. BUY EDUCATORS: REQUEST AN EBOOK REVIEW COPY. Description ; About the Author;

Download Free PDF. Die Design Fundamentals. . The sheet metal working processes is predominantly used in various aspects not only for industrial purposes and also utilized for commercial purposes as well. For that many people are engaged in developing the trends by their innovative ideas. Especially in die design, they made different die set .Design Checkpoint: Why Use Sheet Metal? 4 Tolerances 4 Xometry’s Sheet Metal Tolerance Offerings . part using press brakes and die tools. Parts can be finished with inserts, welding, surface . A .pdf drawing can be attached to the uploaded model if .Download Free PDF. DIE DESIGN FUNDAMENTALS. . Wear at the die radius in sheet metal stamping. Michael Pereira, Bernard Rolfe. Wear, 2012. download Download free PDF View PDF chevron_right. Preparation of Tool Mark Standards with Jewelry Modeling Waxes. Nicholas Petraco. Journal of Forensic Sciences, 2009.

power distribution box on 5.8l v8 95 ford f150

4 Die Design - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document provides information on various aspects of die design, including die clearance, die block design, punch support methods, stock stops, pilots, and strippers. It discusses the importance of proper die clearance and outlines rules of thumb for .The traditional techniques for design of dies for sheet metal operations used in industry are experimental and expensive methods. Using analytical methods we can calculate various design parameters and . A. Smith [7] has studied die design processes for various operation which also include deep drawing of cylindrical cup, he has given .Hence there is an efficient integrated system is needed which will define the design feature that can be converted into manufacturing feature of the sheet metal die. Recently number of sheet metal tooling design software are available in market, but most of available sheet metal modeling software are failed to integrate with CAM system .Die Design is a comprehensive solution for quality die design, supporting associativity with the part design at every stage of die development and including a variety of functions specific to automotive progres-sive dies. Tooling process expertise Part preparation. Efficiently design both straight break and freeform sheet metal parts using a .

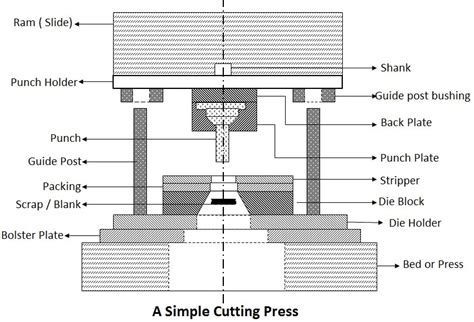

2. CUTTING ACTION IN A DIE The cutting action of sheet metal in press work is a shearing process. Blanking and piercing operations are performed to prepare stock for further processing. The punch is of same shape as of die opening except that it is smaller on each side by an amount known as clearance. as the punch touches the material and travels downwards, .3. DESIGN OF DIE PARTS 3.1 Die The design of die specifically suitable to the bottom plate with respect to the punch. It is made up of plain carbon steel and its hardness is 137 HB. The sheet metal is keeps on moving in the transverse direction in three stations. Independently, these stations can perform their operations individually. Moreover, Cao et al. found that an electrically conductive die has a certain influence on the electromagnetic sheet metal forming and the forming process using the Lorentz force to drive punch for .

tool and die design pdf

EFC9 Metal Locker Cabinet ₱ 14,000.00 Original price was: ₱14,000.00. ₱ 12,500.00 Current price is: ₱12,500.00. Preorder (Delivery lead time 5-10 business days within MM)

sheet metal die design pdf|tool and die design pdf