5-axis cnc machined 5-axis machining is easier and less expensive than you think, and can dramatically increase your profits. This versatile 5-axis universal machining center can position parts to nearly any angle for 5-sided (3+2) machining, or provide simultaneous . Order parts and accessories for all types of CNC machines. Cutting tools, workholders, toolholders, measurement and calibration devices, and more.

0 · large 5 axis cnc machine

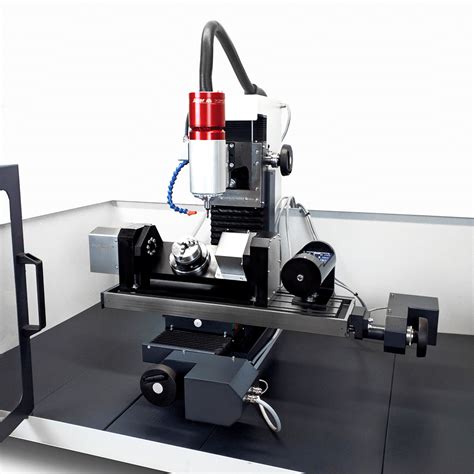

1 · cheapest 5 axis cnc

2 · 5 axis mini cnc machine

3 · 5 axis milling machine price

4 · 5 axis cnc price

5 · 5 axis cnc milling machine

6 · 5 axis cnc machining center

7 · 5 axis cnc machine price

Struggling to source CNC parts? Explore THECNCSOURCE.COM for easy access to top brands like Renishaw, Blum, Heidenhain, Acu-Rite, Zebra Skimmers and more.

5-axis machining is easier and less expensive than you think, and can dramatically increase your profits. This versatile 5-axis universal machining center can position parts to nearly any angle .With a total of ten series, DMG MORI offers suitable 5-axis CNC machines for almost every application. While the CMX U series is the cost-effective entry into 5-sided machining, the compact DMU models open the door to 5-axis simultaneous milling of .

5-axis machining is easier and less expensive than you think, and can dramatically increase your profits. This versatile 5-axis universal machining center can position parts to nearly any angle for 5-sided (3+2) machining, or provide simultaneous . Full 5-axis CNC machining means a machine’s processing ability to move a tool or a workpiece in five different axes simultaneously. 5-axis CNC machining is considered a more evolved and sophisticated version of the CNC machining process. If you’re in the market for a new CNC machine, whether it’s a lathe, router, mill, or other type, we have a comprehensive explanation of 5-axis CNC machines and their benefits so you make the best choice.

Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it along two additional axes (A, B). This capability allows manufacturers to approach the workpiece from virtually any angle .5 Axis CNC machine products by 5thAxis to enhance your machine productivity. Explore a comprehensive range of workholding solutions.FANUC helps take the complexity out of 5-axis machining. With up to 52 years MTBF, FANUC CNC Systems are not only the most reliable in the industry, but are also powerful 5-axis controls with advanced functions for optimal 5-axis tool paths.

The five axes of a 5-axis CNC machine are X, Y, Z (linear) and A and B (rotational). Understanding the unique function of each allows machinists to unlock the full potential and capabilities of the machine. In many machines, the X-axis moves left to right and is most useful for basic linear cuts. In selecting a 5-axis CNC machine, spindle speed is one of the parameters that deal with machining efficiency and surface finish quality. The increase in spindle speed leads to faster cuts, dramatically reducing the cycle time in processes requiring high speed. For instance, parts requiring precision coupled with time efficiency during . 5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, accuracy, speed, and production efficiency.

With a total of ten series, DMG MORI offers suitable 5-axis CNC machines for almost every application. While the CMX U series is the cost-effective entry into 5-sided machining, the compact DMU models open the door to 5-axis simultaneous milling of .

large 5 axis cnc machine

5-axis machining is easier and less expensive than you think, and can dramatically increase your profits. This versatile 5-axis universal machining center can position parts to nearly any angle for 5-sided (3+2) machining, or provide simultaneous . Full 5-axis CNC machining means a machine’s processing ability to move a tool or a workpiece in five different axes simultaneously. 5-axis CNC machining is considered a more evolved and sophisticated version of the CNC machining process. If you’re in the market for a new CNC machine, whether it’s a lathe, router, mill, or other type, we have a comprehensive explanation of 5-axis CNC machines and their benefits so you make the best choice. Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it along two additional axes (A, B). This capability allows manufacturers to approach the workpiece from virtually any angle .

5 Axis CNC machine products by 5thAxis to enhance your machine productivity. Explore a comprehensive range of workholding solutions.FANUC helps take the complexity out of 5-axis machining. With up to 52 years MTBF, FANUC CNC Systems are not only the most reliable in the industry, but are also powerful 5-axis controls with advanced functions for optimal 5-axis tool paths.

The five axes of a 5-axis CNC machine are X, Y, Z (linear) and A and B (rotational). Understanding the unique function of each allows machinists to unlock the full potential and capabilities of the machine. In many machines, the X-axis moves left to right and is most useful for basic linear cuts.

In selecting a 5-axis CNC machine, spindle speed is one of the parameters that deal with machining efficiency and surface finish quality. The increase in spindle speed leads to faster cuts, dramatically reducing the cycle time in processes requiring high speed. For instance, parts requiring precision coupled with time efficiency during .

cheapest 5 axis cnc

Heidenhain CNC Parts HEIDENHAIN develops and produces linear encoders, .

5-axis cnc machined|5 axis cnc milling machine