cnc facing & centering machine Facing is a lathe machining operation in which material is removed from a workpiece’s end using a particular tool. It produces a smooth surface perpendicular to the . Pots - They can work great, easy to change plants and 8" pots easily fit into our Boxes. Colorful pots can perk up any window. Copper Liners - While expensive they last forever and transcend from a bright copper color to a bright blue/green patina given time and the right conditions.

0 · what is a facing machine

1 · turning and facing operation

2 · milling machine facing

3 · manual facing machine

4 · machining facing tools

5 · facing operation in machining

6 · cnc facing operation diagram

7 · cnc facing operation

Kays Kustom Metalworks fabricate parts and bespoke orders for Willys Coupes. High quality metalwork and decades of experience. Worldwide shipping available.

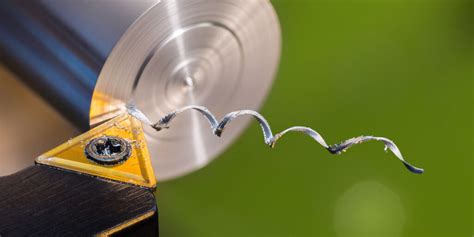

Facing on a milling machine is the process of cutting a flat surface perpendicular to the axes of the milling cutter. This process removes the material by rotating the facing tool in the counterclockwise direction as the table feeds the work piece across the cutter. Face milling can be achieved with an end mill, but is often . See moreIn machining, facing is the cutting of a flat surface perpendicular to some axis of the workpiece. This can be applied in two different areas:• Facing on a milling machine (perpendicular to the axis of . See moreFacing on the lathe uses a facing tool to cut a flat surface perpendicular to the work piece's rotational axis. A facing tool is mounted into a tool holder that rests on the carriage of the See more

Facing operation on a milling machine removes the material by rotating the facing tool in the counterclockwise direction as the table feeds the workpiece across the cutter. The tools for face milling including end mill, face . Facing is a lathe machining operation in which material is removed from a workpiece’s end using a particular tool. It produces a smooth surface perpendicular to the .In machining, facing is the cutting of a flat surface perpendicular to some axis of the workpiece.This can be applied in two different areas: Facing on a milling machine (perpendicular to the axis of movement), which involves various milling operations, but primarily face milling.; Facing on a lathe (perpendicular to the axis of rotation), which is commonly used in turning .Facing, Parting off & Deep Grooving cycle time calculation. Theory, Formulas and Online Calculator

CE-3000 CNC Facing Machine. The CE-3000 CNC Facing Machine is a double turret, high efficiency CNC facing machine designed for shaft applications. Facing and centering cutter; Work pusher unit; Manually controlled vice unit (auto control unit option) FANUC 18i-TB control

what is a facing machine

Clamping Stability: Try to estimate the overall combined stability of your tool and workpiece.If you are unsure, leave it as “average”. Excellent: The workpiece is firmly clamped and supported and the tool is firmly clamped with a short overhang. Poor: The workpiece L/D factor is large (Long shafts) without a steady rest (Luneta) and/or tailstock and/or the tool has a long overhang. [Hindi] CNC Program for Facing Operation | Facing Operation in CNC | How to write CNC Program | CNC In this video you will learn about the part program writi.Product advantages: (milling machine) Original - Turning and cylindrical combination tool Drilling the center hole and turning the outer circle at the same time can be completed in one step, saving time and investment costs. Original - Finely adjustable two-way hydraulic self-centering clamp Achieve quick tool change. No need to reposition and set the tool. Facing is a lathe machining operation in which material is removed from a workpiece’s end using a particular tool. It produces a smooth surface perpendicular to the rotation axis of the workpiece. In machining, facing can be used in two different ways: on a milling machine and on a lathe.. The facing operation on a milling machine includes various milling .

Duplex CNC Machine for Yoke, Universal Joint, Cardan shaft, etc. for doing 'U-drilling, Facing, Fine Boring & Grooving' operations in a single loading with CNC controllers; for size, geometric dimension & tolerance control.

turning and facing operation

CNC turning machine & tools.What is turning.Types of turning. What is turning? Turning is a cutting action for external surface.In this process the cutting tool move linearly while the work piece rotates.The ZX Facing & Contouring heads offer incredible versatility and repeatability. The ZX tooling systems can perform boring, facing, O.D. turning, grooving, taper boring, radius forming, chamfering, recessing, and threading. Internal through coolant is standard across the range. Discover what ZX can do for you.

Facing & Centre Drilling CNC Machine Highly versatile machine for Face Milling and Centre Drilling operation. This machine engages the component simultaneously at both ends, with independent spindle for Milling and Centre Drilling on both side.

Spindle Nose – BT40: A.C Induction Spindle motor power – 2 Nos. kw: 5.5: Nos. of Spindles: 4: Milling Spindle Speed: rpm: 500-2000: Drilling Spindle Speed: 500-2000This section presents the on-line programs which allows to create G-code toolpath (CNC program) for CNC milling machines for facing. Off-line version of these programs for generating G-code you can find here .

Pipe Spool Master™ 80 – 200 Inch. CNC KD Control Standard CNC Beveling, CNC Boring, CNC Facing (Threading with Upgrade to Fanuc or Siemens CNC Control) Machine Capacity OD Wall Thickness Capacity.CellCon’s FC1000-15 CNC Face and Center Machine is heavy duty and built for a 24/7 manufacturing environment. It’s designed for quick set up and changeover: • Save up to 60 Part Programs – 32k Storage • Sliding Adjustment of Self .Cogsdill ZX Systems include Modular Boring Tools, Facing & Contouring heads for precision machining multiple profiles on Horizontal Boring Machines HBMs. Manual operations are converted to CNC Control, improving productivity, .

electrical box wall

Simple Facing CNC Lathe Program Example. Submit by: Machinist. Summary. Simple cnc lathe program to show how a component can be Faced with a tool. This also shows the tool movements. Drawing/Image. CNC Program % N10 .Our multi-head facing and centering machine with flat, inclined or vertical bed is a versatile CNC machine tool for different processing types of shaft parts. It can mill, drill, tap, chamfer and more on both ends of the workpiece with different spindle configurations. It can work simultaneously or alternately, depending on your needs. It has a linear guide and full enclosed protection for .

YOTMT ZK8216- 500/600/700/800 Flat Bed CNC Facing And Centering Machine . shandong youtai machine tool CO,.LTD facing and centering machine with multi-function spindle combination is a special CNC machine tool for machining the end face and center hole of shaft parts. It can complete milling, drilling, tapping, chamfering and other processes on .Upgrade your machining capabilities with our CNC Facing Lathe services. Achieve precise facing operations for your components with efficiency and accuracy. Contact us for superior machining solutions today.CNC FL Series. Meet the Suraj CNC Facing Lathe Machine from Sahil Machines, a top example of precision engineering. This advanced CNC lathe delivers outstanding performance with its strong design and swing capacities from 1600mm to 3000mm. Perfect for turning and facing tasks, it features a powerful servo motor, fast traverses, and a modern .

Sorry if this has been asked before but what is the best way to do a facing operation? Top. Adrian Vectric Archimage Posts: 15143 Joined: Thu Nov 23, 2006 2:19 pm Model of CNC Machine: ShopBot PRS Alpha 96x48 Location: Surrey, UK. Re: Facing. Post by Adrian » Wed Feb 05, 2014 8:33 am.China Top brand combined CNC machine tool manufacturer YOTMT, with kinds of multi-functional spindles drilling milling turning for metal shaft. China famous brand with ISO9001\CE ,over 70 patents. G94 Facing Example. G94 Facing Example:Blank Size: 65mm Diameter 85mm Long:Final Size: 65mm Diameter 82mm Long This program will rapid to X66.Z3. it will then machine the face down to Z0 in three cuts. The first G94 line tells it to face past centreline to X-1.6 at a feed-rate of F.2 The Z axis moves to Z2.. Cuts 1: Z2. 2: Z1. 3: Z0 The cycle stays in the .Straight CNC facing head holder 90º Attachment for G 075 G 180 CNC facing heads Product Power kw Torque.M Speed RPM - U/min Ratio Ø H mm L 1 mm L 2 mm L 3 mm G.075.500 30 4.000 300 1:1 500 300 400 700 G.075.630 40 5.500 250 1:1 630 300 400 700 G.075.800 50 7.000 200 1:1 800 300 400 700 Product ø CNC head Power kW Torque.M

electrical box volumes

Enhance your machining processes with our Conventional Facing Lathes. Achieve precision-facing operations efficiently. Contact us for reliable machining solutions. CNC Facing. CNC Facing – Precise Metalworking. By Omar Uriarte / January 8, 2009 . In the metalworking industry, facing is known as the process of removing metal from the end of a workpiece in order to create a flat and smooth surface. In the past, counterbores and endmills were the popular equipment used for this procedure.

milling machine facing

For the array cable, the pull-in consists of the pulling of the cable into the offshore substation, floating offshore wind turbine or buoyant junction box. For export cables, the pull-in consists of pulling the cable into the onshore transition joint pit as well as into the offshore substation.

cnc facing & centering machine|cnc facing operation