hobart 140 welding sheet metal I am trying to weld 22 gage sheet metal with a Hobart 140. I am using Argon CO2 with solid .030 wire. It keep burning through and making big holes. I have turned the the amp . • Universal Smoker box is compatible with most gas grills, including any er Q 2000 and larger • Imparts natural smoky flavor into gas-grilled foods • Forged with stainless steel for easy upkeep and long-lasting use

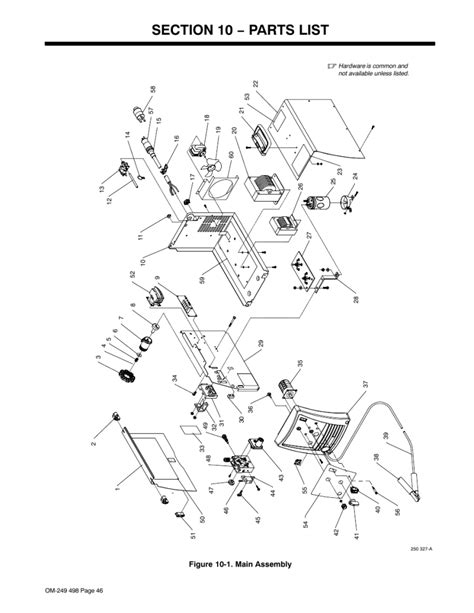

0 · hobart welders parts diagram

1 · hobart welder parts catalog

2 · hobart handler 140 replacement parts

3 · hobart handler 140 parts manual

4 · hobart handler 140 parts diagram

5 · hobart 140 welder parts list

6 · hobart 140 parts list

7 · hobart 140 parts diagram

Find opening & closing hours for Weaver Sheet Metal LLC in 214 South Market Street, Ephrata, PA, 17522 and check other details as well, such as: map, phone number, website.

Deposits a high chromium carbide alloy steel. Can be used to overlay surfaces subjected to high abrasion coupled with some impact. Maintains its wear resistance to a temperature of 1200 .Hardalloy 140 is designed for overlay on carbon, low alloy, or austenitic manganese base metals or a weld metal base of Hardalloy 32, Hardalloy 118, or Chrome- Mang. Today we are going to be welding thin sheet metal to replace old rusted out metal on our 1951 Chevy Panel van. I am trying to weld 22 gage sheet metal with a Hobart 140. I am using Argon CO2 with solid .030 wire. It keep burning through and making big holes. I have turned the the amp .

hobart welders parts diagram

hobart welder parts catalog

Follow requirements in OSHA 1910.252 (a) (2) (iv) and NFPA 51B for hot work and have a fire watcher and extinguisher nearby. Read and understand the Safety Data Sheets (SDSs) and .140-amp MIG welders running on 115V power are best used for thin sheet metal and steel plate up to 3/16-in. You’ll need multiple passes and a good 20-amp electrical circuit to weld thicker materials. For welding 1/4-inch and thicker, a .

The Handler 140 operates on 115-volt common household power. Simply plug it in and weld —no additional power needed. Weld as thin as 24 gauge and up to 1/4 inch in a single pass, with a .

The fine print of Hobart Handler 140 spec sheet notes that you must keep the MIG lead as straight as possible and that the wire feed-ability is not as good when welding steel. This is expected, considering that the machine .

The Hobart Handler 140 is an excellent choice for sheet metal welding due to its versatility and user-friendliness. With an amperage range of 25 to 140A, it’s capable of handling various thin materials, including sheet metal. Setup of a Hobart 140 Mig Welder. All you need to know about how to set up your welder whether your welding with flux core wire or solid wire and gas.There seems to be much difference of opinions on which size wire works best on sheet metal (22 g- 18 g) I've always used .030 in my MM210, harris 20 gauge in my 110 machine. . Hobart Handler 140 - Great 120V Mig Hobart Handler EZ125 - IMO the best 120V Flux Core only machine . One minute I welding body panels the next 5-8mm (1/4 - 3/8 at a .

The American Welding Society (AWS) defines it as 3/16 inch or thinner in its AWS D1.3/D1.3M: 2018 Structural Welding Code – Sheet Steel. As when welding other materials, getting the best results with thin materials depends on correct .

Setup of a Hobart 140 Mig Welder. All you need to know about how to set up your welder whether your welding with flux core wire or solid wire and gas. This v.Filler Metal, Wire & Rod; MIG Welding Consumables; Oxy-Fuel Tips; Helmet Consumables; Projects & Advice. . Replacement 10 ft. HR100 MIG gun for your Hobart Handler 135, 140, 175, 180 or 187 MIG welder. Comes ready to feed .030-.035 diameter welding wire. . Watch as Joel Ort with Hobart Welding Products walks through step-by-step . A few days ago I bought a Hobart 140, a 5 liter tank (75% CO2 – 25% Argon) and 0.030 solid copper wire. I never welded before and have been practicing butt welds on the old floor pans I cut out of my 67 GTO. After setting up my equipment and reading the manual, I read that I should have bought a gas mixture of 75% Argon – 25% CO2 (rather than the mixture I . Just ordered a Hobart 140 and need to choose solid wire. I have an 80cf bottle being hydro'd, revalved and filled with ArCo2 75-25. Which wire should I be running for mainly auto body sheet metal? I plan on trying .023, not sure if it should be ER70s 2, 3 or 6. Thanks!

Then there's another step up to around 0 (Lincoln from the big box places, Hobart etc.). One of these price ranges is what I want. I've also heard some people say that some of these welders are not good for thin sheet metal because the current can't go low enough. For example, it can easily weld automotive sheet metal, furniture frames, or metal doors. On the other hand, the Hobart Handler 140 can weld thicker steel, cast iron, and stainless steel, making it suitable for more industrial applications like trailer fabrication, heavy-duty equipment repairs, or large metal gates. Talk about MIG welding equipment, guns, drive-roll systems, solid and flux-cored wires, etc. . I recently purchased a Hobart 140 and just realized although I have welded many times I have never been the one to buy the gas or wire and now that I'm on my own I am clueless. I will be predominantly working with sheet metal for my vehicles .

hobart handler 140 replacement parts

Today we made our first big purchase using some of the money we made on YouTube all thanks to viewers like you! We thank you! Today we unbox the new handler.

Things to note about warpage: All metal shrinks when melted. If/when you bevel, the welding process puts a small amount of melted metal at the root of the bevel, and a much larger amount of melted metal at the top of the bevel. This causes the part to pull towards the weld. The bigger the bevel the more the pull.Sheet metal, like the body panel, can be welded with a 115 v mig welder like Hobart handler 140 if you are willing to do these 5 things. . . (In fact, the 115 V mig welding machine is usually the best choice for welding sheet metal, and the Hobart Handler 140 has all the features needed to weld thin sheet metal or even up to \"thick steel.) Don\'t even consider trying to weld in a car body .

This is definitely not an instructional video, just a newbie playing with some thin sheet metal! I really need to spend more time learning to weld, as you ca.

My question is Hobart claims that the lowest gauge this welder will do is 24 gauge sheet metal but does that mean I'll just blow holes through anything that's below that because most cars I think are 20 to 22 gauge nowadays which is what i read online. . Hobart Handler 140 Review & Welding: Reply . 05-31-2015 #4. DSW. View Profile View Forum .I was looking at the Hobart 140 but haven't really seen any reviews on how well it would work on cars. . predecessor to the 140. It’s fine for sheet metal and exhaust as long as you use solid wire and shielding gas. . berries, vegetables, sustainability, off grid, wood stoves, chainsaws, wood heat, tools, welding, green woodworking .Later, we’ll go over the tips and tricks of doing sheet metal welding together. Let’s get on with the article, shall we? Contents. Best Welders for Sheet Metal – Comparison Chart . Top-Rated Welders for Sheet Metal. Hobart 500559 . In this video I show you how to properly set up your welder settings for thin sheet metal welding on automotive car or trucks repairs for beginners.In this v.

Handler®140 115-Volt Wire Feed Welder 217919 September 2022 500559 115 V Quick Specs Welding Amp Range 25–140 A Rated Output 90 A at 18.5 VDC, 20% duty cycle Mild Steel Thickness Range 24 ga.–1/4 in. Hobart Welding Products An ITW Welding Company Sales: 800-626-9420 Service: 800-332-3281 HobartWelders.comHardalloy 140 deposits a high chromium carbide alloy steel. It is an excellent general purpose alloy for . When welding vertical, the smaller diameters have better operating characteristics and can be used suc- . Hobart Brothers Company 101 Trade Square East Troy, OH 45373 PH: (800) 424-1543 FX: 800-541-6607 www.hobartbrothers.com . Eastwood 135 and Hobart 140 are welders that use MIG welders for welding sheet metal. The two welders run with a standard amount of volts which run up to almost 240V with the size of their casings, and they are lightweight since they weigh almost 60 kilograms. I have a flux core now and its time to upgrade to start learning how to do some nicer welds as well as have something that I can weld sheet metal with. I was about to buy the Eastwood 135A based on some decent YouTube reviews. It was between that at 9 and the Harbor Freight Titanium 140 at 9.

Talk about MIG welding equipment, guns, drive-roll systems, solid and flux-cored wires, etc. Login or Sign Up . Actual Hobart 140 amperage and wirefeed settings? 01-17-2013, 11:16 AM . After you weld a while you will be be able to look at weld you intend to make (metal thickness and weld type (off normal) and wire type (shield/non-shield . Well obviously I don't want a newbie welding a trailer either, but I am capable of welding 1/4" to 1/4" in a way that the metal will fail before the weld. Now I am not saying you should take two giant plates of 1/4" and try to make a ship, I agree there are limitations, but for a trailer I would be fine, especially if you add some beveling and .Stick welding 14 guage? Collapse. X. Collapse. Posts; Latest Activity; Photos . Search. Page of 3. Filter. . Hobart Handler 140 60cuft Argon, 85cuft C-25 (largest customer owned locally) 145cuft Acetylene, 60cuft Oxygen . Switching polarity is an old sheet metal trick. It will make the rod hotter than the work...when the work is thin .That's my basic story. Just want to try some basic welding. MIG. I'd like to be able to do a tack weld, or weld a nut to a frozen/stripped head, or try some auto sheet metal repair. Seems like Hobart 140 is the way to go, so I will try to find a used one. Or .

For wire, you can get a variety of diameters, which requires different tips for the gun (2seconds to change). If you choose to run the small diameter wire popular for sheet metal (0.024" I think) you may need to get a new roller. You can probably run 0.030 on sheet metal just fine. The tack weld setting is helpful when working with sheet metal and car auto body. It provides consistent tack welds regardless of how long you keep the torch trigger depressed. . It’s a 120V input welder with equal welding power to Hobart 140, but with a slightly higher duty cycle. It’s lightweight, thanks to the latest IGBT inverter .

By incorporating ribs, either through welding or screws, and adding tapers to bends, engineers can significantly boost the rigidity and durability of their designs. Additionally, reinforcing brackets with supplementary components serves as an effective method to bolster structural integrity.

hobart 140 welding sheet metal|hobart 140 parts diagram