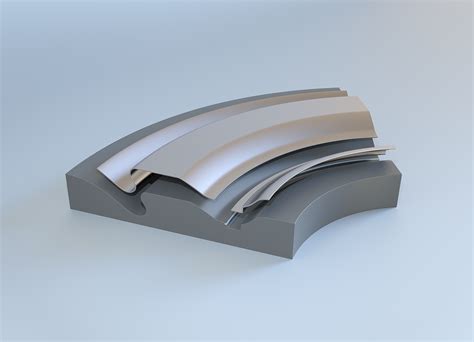

sheet metal lance design The Forming Tool model is separate from the workpiece model being designed. An example for a bridge lance tool is shown in Figure 7a. The Forming Tool model represents the interior of the feature being .

Welding galvanized steel is possible, as it’s just like regular steel but with a zinc coating. By removing this coating, you can weld it like you would with any other steel. You can also weld it with the coating, but there are some important safety precautions you must be .Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc .

0 · thinning in sheet metal forming

1 · sheet metal lance stamping

2 · press forming of sheet metal

3 · lancing process in sheet metal

4 · lancing operation in sheet metal

5 · lance punch dies

6 · how to joggle sheet metal

7 · half shear sheet metal

In this video I share the easy way to fix small holes in sheet metal with a mig welder. This mig welding process works well with rust repair also. The trick .

features into a flat sheet. Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering, lances, half-shears, and weld projections.Curling is the process of forming the sheet metal flange into a rolled shape. Curling strengthens the edges and provides smoothness to the surface. It is commonly used as a means of joining .A Lance and Form is a tool that both cuts (lances) and forms sheet metal. They are a great tool for a variety of applications, including air flow, decoration, card guides, location markers, shear .

Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending.

FORMING TOOLS. 1)HALF SHEAR (SHEAR BUTTON) 2)EMBOSS (DIMPLE) 3)COUNTERSINK FOR COUNTERSUNK SCREW (CHAMFERING) 4)COUNTERSINK. 5)COUNTERSINK BURRING. 6)ONE PITCH . The Forming Tool model is separate from the workpiece model being designed. An example for a bridge lance tool is shown in Figure 7a. The Forming Tool model represents the interior of the feature being .

Sheet metal DFM - design guidelines for formed and punched parts. A first principles look at sheet metal design for manufacturability for experienced engineers. Sheet metal design skills are a crucial tool in any engineer’s .

Following are some basic sheet metal design, Thump rules for Sheet metal Design. 1. Bends. For the ease of manufacturing, multiple bends on the same plane should occur in the same direction. Avoid large sheet metal parts with .Forming tools are a great way to add specific geometry to a sheet metal design. This can range from louvers to lances, to dimples, but forming tools can also help add text or logos to a sheet metal design. This article will help you create .It is recommended that the ratio of the open hem radius to the sheet metal thickness should be greater than or equal 0.5. Also, the ratio of return flange height to the sheet metal thickness should be greater than or equal to 4. Where, H = Return flange height D = Open hem diameter T = Sheet metal thickness

Freelance sheet metal design and drawings services High quality sheet metal manufacturing and fabrication drawings for companies. Get a Quote. Clients: Durable, functional designs for your projects. Sheet metal design is an art that .Following are some basic sheet metal design, Thump rules for Sheet metal Design . The minimum width of a closed lance is two times the material thickness or 1.60 mm (0.06 inch), whichever is greater, and a maximum height . 5 Important Sheet Metal Design Formulas #1 K-Factor. The K-Factor is a crucial parameter used to determine how much a given material will stretch or compress during bending. The K-Factor is used to calculate the Bend Deduction and Bend Allowance (formulas #2 and #3), which in turn are used to determine the correct size of the unfolded flat .

In the realm of sheet metal design, the K-Factor holds significant importance. It’s a constant used to calculate the sheet metal’s bend allowance, informing the flat layout dimensions necessary to achieve a desired bent part. Essentially, K-Factor is a ratio that represents the location of the neutral axis within the thickness of the sheet .Design Library Bridge Lance/Where do I find the "forming tools"? I can't seem to find the forming tools in the design library. I need to put a form in the bottom of this sheet metal but can't find the forming tools in the design library. . Sort by: Best. Open comment sort options. Best. Top. New. Controversial. Old. Q&A. gupta9665 • You may . Sheet metal stamping is a versatile and efficient manufacturing process capable of producing a wide array of complex parts for various industries. However, designing parts for sheet metal stamping requires a specialized understanding of engineering principles and manufacturing limitations.. This comprehensive guide is designed to equip engineers and designers with the .

In Onshape, you can initiate a sheet metal design using several methods: you can convert a solid part into sheet metal; design from a flat sketch, then fold; use flange tools to add edges and features; or directly import and adapt existing sheet metal designs. Simultaneous Sheet Metal.A small team of engineers with over 20 years of industrial experience. We've worked on hundreds of projects, big and small. All the experience we've gained on those projects gives us a thorough understanding of the hands-on application and processes involved in sheet metal fabrication, component design, and manufacturing assembly.

Minimum Distance from Bend to Lance During lancing operation a sufficient degree of clearance should be given around the lance feature and bend. It is recommended that minimum distance between lance and bend should be 3X the material thickness plus bend radius. t = Sheet metal thickness r = Inside bend radius r dA louver in sheet metal design is typically a formed feature made with a punch press incorporating a top and bottom die. When formed the metal is slit across the length of the louver and forced up into the die. The sides of the feature will not be slit. This forms a raised window in the part which is protected on three sides and open on the fourth.I'm starting a new job pretty soon where I will be designing a lot more parts out of sheet metal. I was just wondering if there are any good reference books out there similar to the Black Book series, but for sheet metal design with all the most useful equations, tables of minimum bend radii, guides for relief cuts, etc.Our guides include: Product Guide – Provides an inspiring overview of the different color solutions that Steelscape offers.; Color Design Guide – A comprehensive overview of modern color trends and finish options for metal roofs and walls.; Metal Wall Design Guide – Designed to enlighten building designers as to the shape and color possibilities available with single skin metal wall .

A louver in sheet metal design is typically a formed feature made with a punch press incorporating a top and bottom die. When formed the metal is slit across the length of the louver and forced up into the die. The sides of the feature will not be slit. This forms a raised window in the part which is protected on three sides and open on the fourth.Our sheet metal design for manufacturing eBook is an essential guide for anyone looking to design parts that can be manufactured faster with less back and forth. This ebook provides an overview of best practices in sheet metal design of .There are several ways designers can cut or form the sheet metal into the final part. Manufacturers should take several factors into consideration when designing sheet metal components to ensure an efficient end product. Read the guide below to learn the best DFM tips for sheet metal fabrication. Top 10 Design Considerations for

I am a freelance product design engineer (CSWE Certified). Have 7+ years of experience on plastics design and sheet-metal design. I also cater to automobile industries and ancillaries for Class-A surf. Read more. I am a freelance product design engineer (CSWE Certified). Have 7+ years of experience on plastics design and sheet-metal design.A lance is created instead of trimming material from the strip; Minimizes scrap but creates shaving; Section 7 . Sheet Metal Design Guidelines: Designing Sheet Metal Parts. 11/1/2023. Design for Manufacturability. Preparing Technical Drawings for .Continuing in our series on Design for Manufacturing, this time we’re taking a look at sheet metal design.As the name implies, this involves designing components and assemblies using formed sheets of thin metal. Sheet metal is my favourite construction material as a designer, and I like to think of it as engineering origami.

Behance is the world's largest creative network for showcasing and discovering creative Sheet Metal Design workHere is the list of best sheet metal design interview questions with their answers. What is recommended inside bending radius in sheet metal fabrication? For hard materials (CRCA and stainless steel), the minimum inside radius is 0.7 times of sheet thickness. . Forming tools: sheet-metal rib, louver, lance & Tab .

Joining Materials: SnapLock™ Lance and Form 55 Joining Materials: SnapLock™ with Reinforced Tab56 Knockouts 57-59 Lance and Form 60-61 Bridge Lance and Form 62 Double Bridge Lance and Form 63 Closed End Louver 64-65 Parts Marking: Easymark 66-67 Parts Marking: Sheetmarker 68 Parts Bending: Easybend 69 Parts Bending: Varibend 70-71Sheet metal design skills are a crucial tool in any engineer’s toolbox, but given how little attention sheet metal design gets in academia, most skills are learned on the job. From consumer electronics, to medical devices, and obviously automotive - sheet metal part design plays a role in most modern products. .Optimizing Part Design for Sheet Metal Fabrication. There are many design elements involved in creating parts for sheet metal fabrication—design for cost, quality, assembly, and manufacturability. Navigating that landscape can be challenging at times. At Protolabs, we provide automated design analysis on CAD models that highlights features in . Sheet metal design is a popular material favored by many industries for its strength and durability. Unlike plastic, sheet metal can be used to make a long-lasting product that can handle heat and friction while also protecting more delicate parts. It is very commonly used as housing for electronics, among other things. Many different metals

Bends are the most typical feature of sheet metal parts and can be formed by a variety of methods and machines which negate the absolute need for some of the below tips. . When multiple bends are on the same plane try and design the part so the bends all face the same direction. . The minimum depth of a lance should be twice the material .DESIGNING SHEET METAL PARTS: BEST PRACTICES TIPS AND TRICKS FROM THE SHOP FLOOR. . DESIGN TIPS • Whenever possible, maintain minimum spacing of 2-2.5x raw . • Secondary operations may be required to trim displaced metal. • Design for minimal material displacement. [email protected] | 607.227.7070 | www.incodema.com .

thinning in sheet metal forming

sheet metal lance stamping

press forming of sheet metal

There is one commonality between stick or torch welding thick sections and welding sheetmetal. In both of them, a serviceable weld often, but not always, has a good-looking, even, penetrated, and uniform appearance.

sheet metal lance design|sheet metal lance stamping