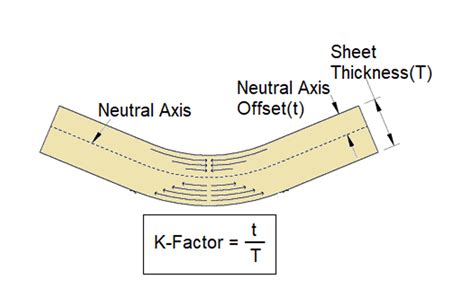

k factor value in sheet metal Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. In this article, we will discuss sheetmetal bend deduction, bend allowance, K . There is a lot of new equipment available, but what really counts is the weld. We offer free estimates. Our services extend to onsite and after hours work. We use auto cad to design to your specifications. Here at P.K. Wade & Sons we work with all types of .

0 · solidworks sheet metal k factor

1 · k factor sheet metal calculator

2 · k factor explained

3 · k factor bending sheet metal

4 · bending calculation for sheet metal

5 · bending allowance in sheet metal

6 · bend allowance k factor chart

7 · 304 stainless steel k factor

CANTEX PVC junction boxes connect effortlessly with our applicable PVC pipe and fittings. The CANTEX junction box can also be used with electrical metal tubing (EMT) as long as proper .

solidworks sheet metal k factor

Once developed, the value of the k-factor will enable you to predict the total amount of elongation that will occur within a given bend. The k-factor allows you to calculate . Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. In this article, we will discuss sheetmetal bend deduction, bend allowance, K . Knowing the k-factor formula is essential in order to bend any kind of sheet metal correctly; in fact, it varies according to the type of material to be deformed. What is the k-factor? The k-factor indicates the behaviour of the .

Use our K-factor calculator to determine the position of the neutral axis in the sheet of metal you are planning to bend.

The K-factor in sheet metal is a ratio to determine where the neutral axis (where the material is neither in compression nor tension) lies within the thickness of the bent material. It is important to predict the bending .

The K-Factor in sheet metal working is the ratio of the neutral axis to the material thickness. When metal is bent the top section is going to undergo compression and the bottom section will be stretched. The line where the transition from . In sheet metal, the K-factor is the ratio of the neutral axis to the material thickness. When a piece of metal is being formed, the inner portion of the bend compresses while the outer portion expands (see Figure 1).Looking for a quick and easy way to calculate the K factor and bend allowance for your sheet metal? Our online calculator is your go-to tool! The K factor is a crucial parameter in sheet .

The sheet metal k factor is a crucial parameter used during the bending and folding process of metal sheets. The degree of deformation of the metal sheet upon bending is indicated and usually represented as a decimal value. The K .

programs to produce accurate sheet-metal work. Many CAD programs, however, also work out bend allowances automatically by using K-factor calculations. (Or Y-factor in the case of Pro-E where Y-factor = K-factor * / 2). Bend allowances are calculated using a K-factor as follows: BA= (R + KT) A/180 where: BA = bend allowance R = inside bend radius Use one of the listed K-Factor calculators and measurement of a sample bent part: K Factors Autodesk Inventor; Inventor K Factor Calculator; Manually calculate the K-Factor using the measure of sample sheet metal .

How to calculate bend allowance, K factor and Y coefficient in one click. To calculate the bend allowance, the K factor and the derived coefficient called the Y factor, insert the thickness and initial length of the sheet into the cells on the left.After bending the sheet, insert the inner radius, and flanges A and B. Bending angle is 90°. In sheet metal design, the K factor is a critical value that influences how the software calculates the bending allowance during the fabrication process. Essentially, the K factor is a ratio that represents the location of the neutral axis (the axis at which the material neither compresses nor stretches during bending) relative to the thickness . How to check the K-factor of the sheet metal fold or bend, and to set the Sheet Metal properties and folding factors to transform the radii according to the material thickness in Inventor. To manage the K-factor in sheet metal parts: 1. Open sheet metal parts or use the Convert to Sheet Metal feature 2. Click the Sheet Metal Defaults 3. To edit or check the K . The K-factor is a standalone value that explains the bending and unfolding of sheet metal in various geometric scenarios. It is also an autonomous value that is used to calculate the Bending Allowance (BA) under various conditions such as different material thicknesses, bending angles, and radii.

Demystify K-factor in sheet metal bending. Learn its importance and how Fabworks ensures precise bends without complex calculations. Sep 9, 2024 . Design Materials. . K-factor isn't a one-size-fits-all value. Several factors can influence it: Material Properties: Different materials have varying levels of ductility and strength, affecting how .To compute the value of K-Factor for an arbitrary bend radius, BricsCAD uses a special interpolation technique which is proved to be valid for industrial sheet metal applications. The image below shows the interpolation strategy: for R/T < 1 the linear interpolation is done between 0 and 0.27324, for 1 < R/T < 4 the K-Factor is linearly .

k factor sheet metal calculator

I work on Solidworks Sheet Metal for designing sheet metal boxes, plates, hoppers,etc. But when it comes to entering K Factor for Mild Steel and Stainless Steel it gets confusing as this affects the blank size. To arrive at 0.0078, the equation uses a k-factor of 0.4468, a commonly used factor that’s the default for many CAD systems. To dial in your bend calculations, you first need to determine whether you go with the default k-factor value of 0.4468, calculate a custom k-factor, or reverse-engineer it based on some test bends.Y factor and K factor represent part constants used in formulas to calculate the developed length of flat sheet metal required to make a bend of a specific radius and angle in a design. . The default value for Y factor is 0.50. Developed length of material and Y factor and K factor. 1. Bent condition. 2. Flat Condition. Where: = Distance .K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of neutral axis and sheet thickness. During sheet metal part bending, the inside bending surface is compressed, whereas the outer surface is stretched.

CAD software often comes pre-loaded with a nominal K-factor value if it has a sheet metal environment. This value varies depending on the material being used. TRENDING: 3Dconnexion CadMouse – Hands On Review. . Sheet Metal | K-factor. Posted by Gavin Bath | May 29, 2013 | Design, .

CATIA V5 is the metal bending software of choice across many industries. This tutorial covers how the K-Factor impacts metal bending and Learn how to calculate the K-factor in Sheet Metal Bending with this CATIA V5 tutorial. The minimum k-factor for air forming can be expressed as (4-π)/π, or 0.27324. We subtract that value from our maximum k-factor value of 0.5: 0.5 - 0.27324 = 0.22676. This result gives us our range of possible k-factors as . What is K-Factor in Sheet Metal Bending? The k-factor is the ratio between the thickness of the metal being bent and something called the “neutral axis/line.” The neutral axis is an invisible line that splits the thickness of the .You can specify different values for the K-Factor in different configurations. You can also apply a material-based default K-Factor by using a Sheet Metal Gauge table. Bend allowance with a K-Factor is calculated as follows: BA=pi(R + KT) A/180. where: BA = bend allowance;

We use a bend table for our sheet metal in inventor and we need to know what k-factor the bend table is using. How can the information inside the bend table (correction value x) be used to calculate a k-factor?Start a new part > create a base flange > set the sheet metal parameters to whatever you want > delete the base flange feature and any sketches > save as part template > enjoy your new defaults Extra tip: K factor is a dimension that can be used in custom properties. The syntax is "D2@[email protected]". I have my templates set so .

Bend Allowance (mm): Material Thickness (mm): Bend Angle (degrees): K Factor: Calculate The K Factor in sheet metal bending is a crucial parameter that helps in determining the correct bend allowance and bend deductions for creating accurate sheet metal parts. It is essential for ensuring that the final dimensions of the bent parts match the . radians is included, so you would enter θ directly . Ever wonder what "K-Factor" means when defining your Sheet Metal Rules in Fusion 360? This Quick Tip provides more insight on how the K-Factor is used to det. On the other hand, part created using sheet metal gave me the difference between lengths 0.91mm (which is too big difference for me). For the difference is responsable K-factor, so my question is (from the beginning: What is the value of the K-factor to get the same values before and after bending in sheet metals?

When customers search for a Sheet Metal K Factor Chart on Google, they are typically seeking detailed information to assist them in the design and fabrication. Skip to content +86-13770803946; . Look for the corresponding K Factor value for your material thickness. This value will be used in flat pattern calculations.

Explore the pivotal role of sheet metal K Factor in precision engineering and how it transforms your fabrication projects for the better. . The degree of deformation of the metal sheet upon bending is indicated and usually represented as a decimal value. The K-factor value depends on various factors, including the material properties, sheet .

What I do is check the "Override default parameters" on the sheet metal feature. Then, while in context of the assembly, I double click on the body. This will show your sheet metal dimensions (thickness, radius, and K factor for me). Then you can modify the thickness by double clicking it, and then link it to your assembly level custom property.

$9.99

k factor value in sheet metal|k factor bending sheet metal