best mig wire size for sheet metal The selection of the correct MIG welding wire size comes down to your project’s specifics – the material thickness and joint design. As a seasoned welder, I’ve found that a larger wire size is often more suitable for thicker . Shop Wayfair for all the best Metal Twin Beds & Frames. Enjoy Free Shipping on most stuff, even big stuff.

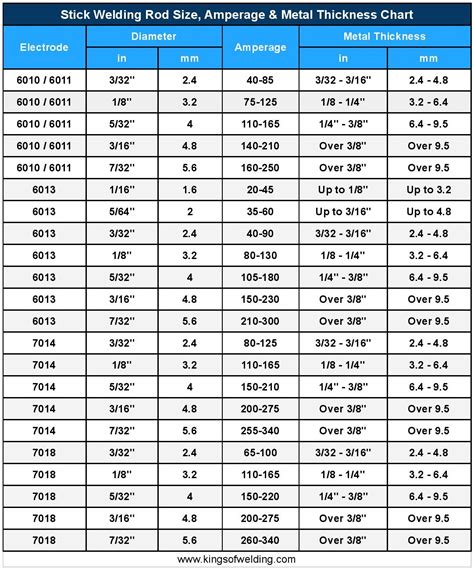

0 · welding wire diameter chart

1 · welding thickness chart

2 · welding mig wire size chart

3 · weld wire selection chart

4 · mig wire diameter chart

5 · mig welding wire size selection

6 · mig welding wire size explained

7 · mig welding sheet metal basics

Make craft & fashion projects stand out with bright, dimensional paint colors from Tulip! This nontoxic paint is used by crafters of all skill levels on everything from educational crafts to statement T-shirts, canvas art, personalizing accessories, gift .

Whether working with thin sheet metal or thicker stock, selecting the right MIG wire size is crucial for preventing problems such as poor arc starts, burn-through, or warping. Let’s dive into the practical solutions to keep your welding operations smooth and consistent.

Once a wire type is determined for your welding equipment, two additional pieces of information are needed in order to purchase this consumable. The first is the wire diameter, .

welding wire diameter chart

welding thickness chart

The selection of the correct MIG welding wire size comes down to your project’s specifics – the material thickness and joint design. As a seasoned welder, I’ve found that a larger wire size is often more suitable for thicker . Some wire and gas combinations commonly seen with MIG welding are: Mild/carbon steel – ER70s wire and 75/25 percent ratio of Argon to CO2; Stainless – ER308L wire and 98 percent Argon with 2 percent CO2; Aluminum . MIG wire sizes typically range from 0.023 to 0.045 inches, and selecting the appropriate size depends on the metal thickness being welded. The wire acts as the filler material that melts and joins metal pieces together during . Using 0.023, 0.024, and 0.030 in MIG solid wires for sheet metal is best. Also, avoid a 100% CO2 shielding gas because it amplifies penetration, which leads to burn-through. The best shielding gas for MIG welding thin mild .

This chart is a helpful guide for choosing the correct wire size and type (solid or flux) of wire based on the thickness of the material being welded. Whether working with thin sheet metal or thicker stock, selecting the right MIG wire size is crucial for preventing problems such as poor arc starts, burn-through, or warping. Let’s dive into the practical solutions to keep your welding operations smooth and consistent. In this blog post, we will explore the key factors that affect MIG welding sheet metal, including wire size, gas selection, amperage, and voltage. We will also provide tips and best practices to help you achieve optimal welding results. Once a wire type is determined for your welding equipment, two additional pieces of information are needed in order to purchase this consumable. The first is the wire diameter, which is usually given in thousands of an inch. The most .

The selection of the correct MIG welding wire size comes down to your project’s specifics – the material thickness and joint design. As a seasoned welder, I’ve found that a larger wire size is often more suitable for thicker materials and joints requiring deeper penetration, such as beveled joints. Some wire and gas combinations commonly seen with MIG welding are: Mild/carbon steel – ER70s wire and 75/25 percent ratio of Argon to CO2; Stainless – ER308L wire and 98 percent Argon with 2 percent CO2; Aluminum – ER4043 wire and 100% Argon shielding; You choose your wire size by the amperage setting, which in turn depends on material . MIG wire sizes typically range from 0.023 to 0.045 inches, and selecting the appropriate size depends on the metal thickness being welded. The wire acts as the filler material that melts and joins metal pieces together during welding. Choosing the right MIG welding wire size is very important for a strong and lasting weld.

Using 0.023, 0.024, and 0.030 in MIG solid wires for sheet metal is best. Also, avoid a 100% CO2 shielding gas because it amplifies penetration, which leads to burn-through. The best shielding gas for MIG welding thin mild steel sheets is the 75% argon and 25% carbon dioxide mixture.This chart is a helpful guide for choosing the correct wire size and type (solid or flux) of wire based on the thickness of the material being welded. It’s recommended to use a .023- or .024-inch wire for most light gauge sheet metal work. When the material is 18-gauge and thicker, you may be able to use a .030-inch wire. To weld mild steel, choose an American Welding Society classification wire such as ER70S-6, which has a weld puddle that wets out nicely.

For example, when welding sheet metal, the most common wire sizes are 0.35 and 0.45 inches. However, when welding thin steel, you’ll probably need a solid MIG wire with a smaller diameter, either 0.24 or 0.30 inches. Whether working with thin sheet metal or thicker stock, selecting the right MIG wire size is crucial for preventing problems such as poor arc starts, burn-through, or warping. Let’s dive into the practical solutions to keep your welding operations smooth and consistent. In this blog post, we will explore the key factors that affect MIG welding sheet metal, including wire size, gas selection, amperage, and voltage. We will also provide tips and best practices to help you achieve optimal welding results. Once a wire type is determined for your welding equipment, two additional pieces of information are needed in order to purchase this consumable. The first is the wire diameter, which is usually given in thousands of an inch. The most .

welding mig wire size chart

The selection of the correct MIG welding wire size comes down to your project’s specifics – the material thickness and joint design. As a seasoned welder, I’ve found that a larger wire size is often more suitable for thicker materials and joints requiring deeper penetration, such as beveled joints. Some wire and gas combinations commonly seen with MIG welding are: Mild/carbon steel – ER70s wire and 75/25 percent ratio of Argon to CO2; Stainless – ER308L wire and 98 percent Argon with 2 percent CO2; Aluminum – ER4043 wire and 100% Argon shielding; You choose your wire size by the amperage setting, which in turn depends on material . MIG wire sizes typically range from 0.023 to 0.045 inches, and selecting the appropriate size depends on the metal thickness being welded. The wire acts as the filler material that melts and joins metal pieces together during welding. Choosing the right MIG welding wire size is very important for a strong and lasting weld. Using 0.023, 0.024, and 0.030 in MIG solid wires for sheet metal is best. Also, avoid a 100% CO2 shielding gas because it amplifies penetration, which leads to burn-through. The best shielding gas for MIG welding thin mild steel sheets is the 75% argon and 25% carbon dioxide mixture.

This chart is a helpful guide for choosing the correct wire size and type (solid or flux) of wire based on the thickness of the material being welded. It’s recommended to use a .023- or .024-inch wire for most light gauge sheet metal work. When the material is 18-gauge and thicker, you may be able to use a .030-inch wire. To weld mild steel, choose an American Welding Society classification wire such as ER70S-6, which has a weld puddle that wets out nicely.

weld wire selection chart

mig wire diameter chart

mig welding wire size selection

mig welding wire size explained

Rare New York Photo Frame This is a really rare pre- 9/11 New York Landscape / Landmark photo frame, which features 3D textured metalwork of the Statue of Liberty, Brooklyn Bridge, Empire State Buildi.from

best mig wire size for sheet metal|mig welding wire size explained