mig welding rusty sheet metal The best process for thin metal that has rusted is MIG welding. TIG is excellent for thin metal but has trouble if it’s rusted. Stick welding and flux-cored wires cannot weld very thin metals even if they are rust-free because . Purchase your Vertical 911 Address Sign from SafetySign.com with low pricing, 10% discount on sign-up & fast shipping.

0 · welding 20 gauge sheet metal

1 · welding 14 gauge sheet metal

2 · welder settings for sheet metal

3 · mig welding travel speed chart

4 · mig welding thin metal videos

5 · mig welding sheet metal basics

6 · mig welding automotive sheet metal

7 · best welding for thin metal

$79.99

On this episode of make a custom I pull the 81 G10 Van in for a rust repair patch step-by-step mig welding. Check out how to make your own tucking fork here: • How To Make a Tucking Fork to.

We are going to show you how to weld sheet metal that is rusted out and in bad shape. This is very common in the welding restoration of old cars and tractors. Today's weld project is a. In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and weld it in. I demonstrated this.

The best process for thin metal that has rusted is MIG welding. TIG is excellent for thin metal but has trouble if it’s rusted. Stick welding and flux-cored wires cannot weld very thin metals even if they are rust-free because . Use a wire brush or grinder to clean the metal. Clean metal leads to better welds. Wipe the surface with acetone or a similar solvent. This removes any remaining contaminants. .

Master the Art of Rust Repair on Sheet Metal with Luke Merrill. Discover expert insights on repairing rust corrosion through fabrication and welding techniques. Learn step-by-step instructions to restore your metal . The problem with welding sheet metal or thin gauge steel is that you can easily blow holes in the panel and create a big mess quickly. We decided to give you some tips when . Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc . Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these common tips to help ensure success.

Here's some tips if you're having trouble mig welding thin sheet metal. Check out my custom mini parts available:Urchfab Front Subframe Kit: https://www.ebay.

Sheet metal MIG Welding 101Episode 85 Manic MechanicRobert McCartney from McCartney Paint and Custom came in to give welding tips for those using a MIG welde. In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and we. For thinner gauge sheet metal like 18 or 20 gauge we suggest .023 (6mm) wire in your MIG welder. Keep the Stick Out Short-Stickout of your MIG wire is important when welding any type of metal, but especially sheet metal. Holding the tip too far from the surface will cause the wire to have to come out too far to touch the metal.

Welding sheet metal with a flux core is feasible for thin materials. This process utilizes a flux-cored wire to shield the weld pool. . offers advantages like deep penetration and a forgiving nature when dealing with rusty or dirty metal. . MIG or TIG welding is typically recommended for precise sheet metal work due to its better heat control.

Mig welding sheet metal requires precision and control to prevent warping or burn-through. A thin wire and low heat settings are essential. Skip to content. November 17, 2024 . oil, and rust. Use a wire brush or grinder to clean the metal. Clean metal leads to better welds. Wipe the surface with acetone or a similar solvent. This removes any . This mig welding process works well with rust repair also. The trick . In this video I share the easy way to fix small holes in sheet metal with a mig welder. This mig welding process works well . Plug welding kits include pre-cut blanks in multiple sizes plus a step-style bit for drilling sheet metal. Sheet metal patch – If you lose control of the blow-through altogether, you may need to remove the damaged area entirely and start over. Grind out the damage and cut a patch panel from another piece of sheet metal just large enough to . On this episode of Make It Kustom, I continue to repair the rust on the GMC G10 boogie van. We talk in depth about technique for repairing rust and welding o.

I did some metal bodging today, made up wheel arch repair sections for a Rover Metro I used my 5" with plastic backing and a coarse disc, changed it regularly to keep a sharp cutting edge, less heat into the metal, will use the discarded discs when I can grind something nearer to the centre, I was welding a fag packet to a rizla paper so used . I was going to throw away my rusty old lawnmower panel (see photos in post #1) but, before I did, I thought I'd have a crack at arc welding it, just to see what happened. As mentioned above, I hope to try out each of MIG, TIG and Arc welding on some rusty scrap metal before I go anywhere near a rusty old panel on my car.Patch panels are not readily available without buying a whole quarter panel section to cut that part out of. Thats a bit spendy to get a short section of metal repaired. Most of the rusted area have lost only 1/3 of the metal but there are a few rust throughs where perhaps a steel patch could be patched in place. Other spots are thin with pinholes.

sheet metal fabrication nh

We dive into all the details on what you need to flux core weld and how you can repair your project car rust with sheet metal and welding. . Welding Type: MIG*/Flux: MIG/Flux: Upgrades *MIG Starter Kit Required for MIG Welding: Spool Gun for aluminum: Max Material Thickness: 1/8 Inch: 3/16 Inch: Input Voltage: 120V:For example, a 6011 welding rod is good for welding rusty and thin metal, while a 7018 welding rod is better for thicker, clean metal. It is important to research and select the right welding rod for the specific job at hand, as using the wrong rod can .Practice will help a lot. Sheet can be tricky to learn which makes it a good way to start. If you can weld sheet you can weld lot of other stuff easily. Also a welding backing spoon can be very handy for sheet metal work. It'll help support the metal and reduce burn thru a bit. You can get a cheap one at Harbor Freight or any welding supply shop. Use a Correct Mig Wire Size for Different Gauge Sheet Metal. If you are welding light gauge sheet metal, a .023- or .024-inch wire is the best option. But if the gauge sheet metal is slightly thicker, you can use a .030-inch .

I have a rust hole in my front wheel well that I want to try repairing myself. I don't have a welder, but I do have a torch that I can use for brazing. I haven't brazed before, but I've been doing some reading about it, and I know that to braze a joint the metal needs to be very clean, and the tw. Techniques for MIG welding thin sheet metal. MIG welding thin sheet metal requires specific techniques to ensure a successful weld. Here are some tips to help you achieve high-quality welds: Maintain a short arc length: Keep the arc length as short as possible without touching the metal. A shorter arc length helps to minimize heat input and . Stick welding with 6010 and 6011 rods on pure rusted metal is the best option without any surface cleaning. If you can grind and clean the surface the MIG welder will do a much better job and give a more aesthetically pleasing weld.

How to Weld Rusty Metal. Stick welding, or Shielded Metal Arc Welding (SMAW), is the best option for welding rusted metal. This is because stick welding uses flux-coated electrodes that burn through the rust. In addition, the welding rods for rusty metal contain de-oxidizers that help to neutralize contaminants in the weld. Here are the basic . This video is a tutorial on welding thin metal with the UNIMIG VIPER 185Email: [email protected] Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt.

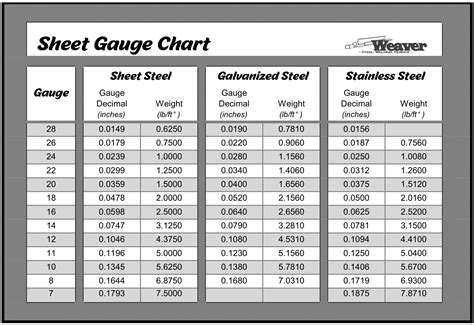

While I'm grinding and removing rust from the car, I'll still be looking at possible alternatives but if none is to be found within my budget, I guess the MIG 160er is the way to go. You're correct, the guy in the Stahlwerk video didn't use the ST 155. . All the information that you can find on this Forum about MIG welding thin sheet metal . In this video I share with you some awesome mig wire I found for sheet metal. This welding wire is great for rust repair and any sheet metal work. This wire .Chad Rustin, owner/operator of Rusty Metal Welding in Stillwater, MN has been providing quality craftsmanship since 1995. Chad is open to nearly any welding or fabrication job you can think of. Custom Work Included! For local, quality workmanship and great pricing on .YESWELDER 8" MIG Welding Pliers, Anti-Rust MIG Welding Pliers for Professional Welding & Round Dual Sided Metal Sheet Guage & Metal Sheet Thickness Gauge 2pk Stainless Steel Welding Gauge - Amazon.com . Gauging uncoated sheet, plate iron and steel; leather, paper, wood, Bolt and more; Wire/Metal Sheet Thickness Welding Gauge:Checking metal .

Welding nearly always causes some distortion: the metal in and around the weld shrinks as it cools, and this shrinking often upsets the shape of the metal. Sheet metal is particularly sensitive to this type of distortion (often called warping) but there are ways to mitigate this characteristic, which we will detail here.

welding 20 gauge sheet metal

transformative garden solutions. *Corten products arrive in a raw steel state.how to rust corten steel

mig welding rusty sheet metal|mig welding thin metal videos