cnc machine coolant reusable Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid chip removal. This article discusses how CNC coolant works, and its delivery technique. Easily slice through tender filets with the eight piece mignon steak set from Wusthof. This set includes eight stainless steel steak knives and an olivewood .

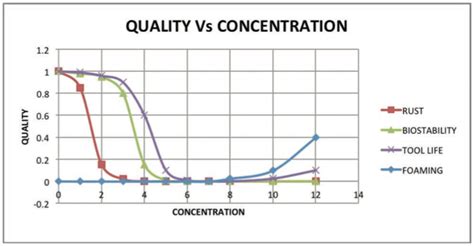

0 · machine coolant concentration chart

1 · coolant tank for cnc machine

2 · coolant system for milling machine

3 · coolant mixers for cnc equipment

4 · coolant concentration for cnc machines

5 · cnc machine coolant suppliers

6 · best semi synthetic machine coolant

7 · best coolant for cnc machine

FANUC America provides the fastest and most reliable CNC support 24/7, including parts, tech support, on-site service and repair, parts repair, and training.

Coolants are vital to CNC machining, not only for maintaining optimal temperatures but also for ensuring effective lubrication, extending tool life, and improving the surface finish . No matter what type of CNC machining you do, CNC coolants play a critical role. They help increase tool life and offer a better surface finish on the machined parts. By understanding the available coolant types, you can select a . Coolants are vital to CNC machining, not only for maintaining optimal temperatures but also for ensuring effective lubrication, extending tool life, and improving the surface finish of machined parts.

why? i consider any machine that has anything but thin oil on table and vise a problem to keep clean. coolant can often dry and create rust and or a sticky or tar like residue that has thickness and rust is actually removing metal.

Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid chip removal. This article discusses how CNC coolant works, and its delivery technique. We run Toyoda horizontals with twin 5 HP coolant pumps. The Yodas have a washdown that makes Mazak's Niagara coolant look like a small drip in the roof during a light rain. It’s important to choose the right type of CNC machining coolant based on your specific machining requirements. Consider factors such as cooling capacity, lubrication, corrosion prevention, and compatibility with the material being machined.

Choosing the right coolant is essential for maintaining the efficiency and performance of your CNC machining operations. By consulting with your coolant supplier and selecting a coolant with anti-foaming properties, you can prevent foaming, enhance lubrication, and improve machining performance. Versakut 7227 is a multi-purposeful synthetic coolant for grinding, machining, milling, and other CNC applications. Made with a biostatic lube package that will not break down or be subject to selective depletion, Versakut 7227 . Coolant helps dissipate this heat, ensuring consistent machining results. Lubrication: Reducing friction between the tool and the workpiece is crucial. A good coolant acts as a lubricant, reducing wear and tear on the tools, and ensures a smoother cut. Chip Removal: As the CNC machine works, it generates chips. Selecting the wrong coolant could compromise your CNC machine’s performance, leading to increased tool wear, overheating, or poor surface finishes. But understanding how coolant works and why it matters will help you unlock your machine's full potential and keep production flowing smoothly.

No matter what type of CNC machining you do, CNC coolants play a critical role. They help increase tool life and offer a better surface finish on the machined parts. By understanding the available coolant types, you can select a .

machine coolant concentration chart

Coolants are vital to CNC machining, not only for maintaining optimal temperatures but also for ensuring effective lubrication, extending tool life, and improving the surface finish of machined parts. why? i consider any machine that has anything but thin oil on table and vise a problem to keep clean. coolant can often dry and create rust and or a sticky or tar like residue that has thickness and rust is actually removing metal.

1972 el camino sheet metal

Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid chip removal. This article discusses how CNC coolant works, and its delivery technique. We run Toyoda horizontals with twin 5 HP coolant pumps. The Yodas have a washdown that makes Mazak's Niagara coolant look like a small drip in the roof during a light rain. It’s important to choose the right type of CNC machining coolant based on your specific machining requirements. Consider factors such as cooling capacity, lubrication, corrosion prevention, and compatibility with the material being machined.

Choosing the right coolant is essential for maintaining the efficiency and performance of your CNC machining operations. By consulting with your coolant supplier and selecting a coolant with anti-foaming properties, you can prevent foaming, enhance lubrication, and improve machining performance. Versakut 7227 is a multi-purposeful synthetic coolant for grinding, machining, milling, and other CNC applications. Made with a biostatic lube package that will not break down or be subject to selective depletion, Versakut 7227 . Coolant helps dissipate this heat, ensuring consistent machining results. Lubrication: Reducing friction between the tool and the workpiece is crucial. A good coolant acts as a lubricant, reducing wear and tear on the tools, and ensures a smoother cut. Chip Removal: As the CNC machine works, it generates chips.

coolant tank for cnc machine

coolant system for milling machine

1972 dodge charger sheet metal

1976 nfl metal lunch box

Left fuse box is the battery fuse box for all items that need constant power. Middle fuse box is accessory fuse box for items receive power when the key in on or accessory position. The third fuse box is powered when the parking lights are on.

cnc machine coolant reusable|best semi synthetic machine coolant