sheet metal materials pdf Selection of Sheet Metal Fabrication Materials Stainless Steel Stainless steel is available in several different types depending on the needs of your application. Austenitic stainless steel is non-magnetic with high chromium levels used mainly for its resistance to corrosion and high formability. Ferritic stainless steel is 4 in 1 Pattern. No instruction manual. Stainless Steel.

0 · sheet metal stamping process pdf

1 · sheet metal specifications pdf

2 · sheet metal manufacturing process pdf

3 · sheet metal handbook pdf

4 · sheet metal guidelines pdf

5 · sheet metal fabrication handbook pdf

6 · sheet metal design handbook pdf

7 · sheet metal basics pdf

Buy ZVex Effects Vexter Box of Metal Distortion Guitar Effects Pedal: Distortion & Overdrive - Amazon.com FREE DELIVERY possible on eligible purchases

Objectives. By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and environmental .Understanding the fundamentals of sheet metal fabrication ; The properties of sheet metal materials including aluminum, stainless steel, cold-rolled steel, and beryllium copper; The forming basics, cutting methods, and springback management of sheet metal ; Design guidelines for curls, hems, holes, slots and more ; Why you should choose sheet .Selection of Sheet Metal Fabrication Materials Stainless Steel Stainless steel is available in several different types depending on the needs of your application. Austenitic stainless steel is non-magnetic with high chromium levels used mainly for its resistance to corrosion and high formability. Ferritic stainless steel is

Sheet Metal Forming: Fundamentals describes the changes that occur in sheet metals during forming operations and explains how to model and analyze them using computational techniques. It begins with a review of sheet forming .1 Material properties 1 1.1 Tensile test 1 1.2 Effect of properties on forming 10 1.3 Other mechanical tests 12 1.4 Exercises 13 2 Sheet deformation processes 14 . sheet metal engineers and mechanical metallurgists in industry and particularly in the automotive field. The aim is to bring students as quickly as possible to the point whereSteel Materials Catalog - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document lists the locations and contact information for stocking and non-stocking locations of Pacific Steel & Recycling across Montana, Idaho, South Dakota, Utah, Washington and Wyoming. It provides addresses, phone numbers and fax numbers for over 30 different locations.Sheet metal material stock has general tolerances for thickness. The following table is a quick reference for standard aluminum 5052 material thickness tolerances. Standard stock material tolerances may vary between alloys and treatments. Sheet metal with tighter tolerances sheet can be specified if required. Stock Material Thickness Tolerances

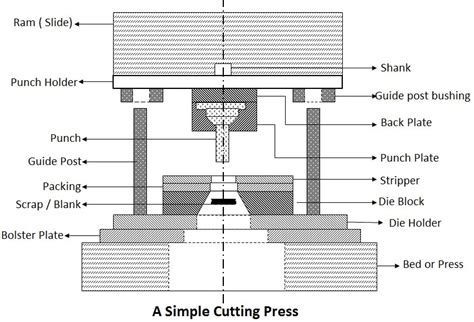

1. Press tool operations are classified as cutting, non-cutting, and hybrid operations. Cutting operations include blanking, piercing, cut-off, and parting-off which cut shapes from sheet metal. 2. Blanking produces flat stampings by cutting the entire periphery. Piercing makes holes in stampings by cutting the entire periphery. Cut-off separates material along a straight line in a .Edited by Taylan Altan and A. Erman Tekkaya ASM International® Materials Park, Ohio 44073-0002 www.asminternational.org Sheet Metal Forming FUNDAMENTALSºõ³ .Sheet-metal based molds for low-pressure processing of thermoplastics R. Appermont & B. Van Mieghem & A. Van Bael Cel Kunststoffen, Department of Industrial Sciences and Technology (KHLim), Diepenbeek, Belgium J. Bens & J. Ivens Department of Metallurgy and Materials Engineering (KU Leuven), Leuven, Belgium H. Vanhove & A. Behera & J. Duflou PMA .

5 • Blend Create a sheet metal wall by blending several sections sketched in parallel planes as shown in Figure SM.10. Figure SM.10 Base Feature, Blended Wall • Flat Sketch the boundaries of the wall (Fig. SM.11). Figure SM.11 Feature, Flat Wall • Offset Create a wall that is offset from a surface (Fig. SM.12). Figure SM.12 Base Feature, Offset Wall .Sheet metal forming Operations Process Details Roll forming Long parts with constant complex cross-sections; good surface finish; high production rates; high tooling costs. Stretch forming Large parts with shallow contours; suitable for low-quantity production; high . Material Grade IF IS513 Gr.D IS513/EDD HSQCR 450 GA (GALV / ANN) SPRC 40

Request PDF | On Nov 13, 2024, Bharat Bhushan and others published Numerical Modeling of Incremental Sheet Metal Forming Process for Generating Complex Shapes on Ti6Al4V | Find, read and cite all .DIY Sheet Metal Derringers The following simple .22 rimfire designs utilize sheet metal plate for ease of construction without access to conventional machining equipment. Each model can be made in relatively short order and adapted to whichever materials or tools are at hand. In all instances pins or bolts can be used in place of welding or . PDF | This paper focuses on material optimization by reduction in raw material size for sheet metal components. Panel roof, an automobile component is. | Find, read and cite all the research you .

Insert Bends or “Convert to Sheet Metal” features. When designing with sheet metal, it is important to think about the best approach to model or design a part. At times, it may appear quicker to use non-sheet metal features (boss-extrude, etc.), and then insert bends or convert to sheet metal. However, these options are problematicSheets of Nirosta stainless steel cover the Chrysler Building. Microscopic close-up of mild steel sheet metal. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.. Thicknesses can vary significantly; extremely .This document provides guidelines for sheet metal forming and bending. Some key points include: 1) Dimensions should generally be from a feature to an edge and avoid feature-to-feature dimensions over multiple planes to control tolerance accumulation. 2) Inside bend radius should be equal to material thickness to avoid material flow problems or fracturing. Bend relief is also .

Sheet Metal Forming of Lightweight Metallic Materials Yong Hou 1,† , Dongjoon Myung 1, † , Jong Kyu Park 2 , Junying Min 3 , Hyung-Rim Lee 1 , Ali Abd El-Aty 4 , * and Myoung-Gyu Lee 1, *

Sheet Metal Skills: Tools, Materials, and Processes provides a comprehensive view of the sheet metal industry and the work involved in it. This write-in text includes up-to-date information on the tools, materials, and processes used in the industry. It includes an overview of sheet metal history, sheet metal uses, and processes used in the . Steel is one of the most useful materials in the world. In the simplest context, steel is composed of iron and carbon, but in actuality, steel isn’t so simple. . Steel standards for architectural metal fence systems . Designation. . Standard specification for steel sheet, metallic coated and polymer precoated for corrugated steel pipe .

Standard for Architectural Sheet Metal (ASM) Systems . Table of Contents . PART 1 - General . Please note that the PDF highlights only the changes made since the last published revision of these Standards. . means a sheet material, either self- adhered or mechanically fastened, which serves as secondary protection .

This guide explores the factors that affect the performance of sheet metal parts and helps you determine how to choose the right metal material for your custom steel parts. 3/1/2023 PDF Filesheet metal material - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document provides information about sheet metal work including: - Sheet metal is metal less than 2mm thick that can be formed into various shapes using hand tools or machines. - Common metals used include galvanized iron, black iron, tin plate, copper, stainless steel, and aluminum. The Sheet metal material selection during product design impact the sheet metal part design, manufacturing process, cost, and part performance. This is a short reference tool to help you choose the best material for your next sheet metal project. It specifies key characteristics such as tensile strength, elongation, and hardness to ensure you have the best material for .

1971 mustang sheet metal

1 Material properties 1 1.1 Tensile test 1 1.2 Effect of properties on forming 10 1.3 Other mechanical tests 12 1.4 Exercises 13 2 Sheet deformation processes 14 . sheet metal engineers and mechanical metallurgists in industry and particularly in the automotive field. The aim is to bring students as quickly as possible to the point whereWorkshop Practice Series 08 Sheet Metal Work. Category : Workshop Practice Series: Language: English: File Type: PDF: PDF : 53: Views : 4,713 views: File Size & Downloads: . Mathematics PDF Books, Notes and study material for students, we have thousands of .

sheet metal stamping process pdf

sheet metal specifications pdf

Upgrade your sleep with Zinus 7 inch Metal Smart BoxSpring. Quick assembly, queen size.

sheet metal materials pdf|sheet metal guidelines pdf