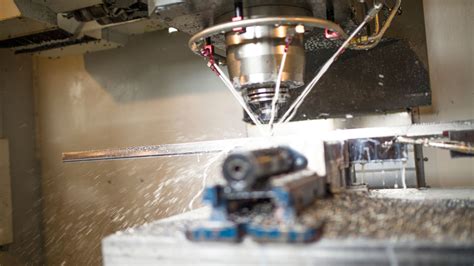

cnc machinery cost applied to part cost Learn how CNC machining costs are calculated, including material types, batch sizes, machining time, and strategies to reduce expenses in your CNC projects. CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. .

0 · round cnc milling cost

1 · round cnc machining cost

2 · cost of cnc machining

Multipurpose ships with flexible cargo holds and equipment can transport many cargoes. From machines and trucks to bulk materials, general cargo ships maintain supply networks and efficient transportation. The loading, unloading, and stowage of these ships require careful planning and coordination.

The cost of a CNC etcher will largely depend on the power of the laser installed on it as well as the size of the bed area. Entry-level CNC machines cost around 00, while more advanced industrial machines cost over 0000. Cross-section capability also provides .

Learn how CNC machining costs are calculated, including material types, batch sizes, machining time, and strategies to reduce expenses in your CNC projects.

Over the past four decades, manufacturers using CNC machines have developed and refined a range of practices to reduce part costs, regardless of production quantity. As we look ahead to 2030, these practices will continue to evolve, with a focus on standardization, quality control, lean manufacturing, and the reshoring of production to the USA. The need for low cost easy to upgrade or replace CNC controls is overwhelming. Considering the cost of CNC machinery the controls should built to be easily repaired or upgraded to last as long as the machine. As machine owners become more tech savy over time hopefully this will happen. Materials x markup /quantity used (tells me what to charge. My cost and how many lengths to buy) Cad time Setup lathe Setup mill Consumables cost One time purchases for job Lathe/pc Mill/pc Handling/pc This spits out a bunch of data points for me to consider. This allows me to play with the numbers quickly to provide multiple quantity quotes.

If you insist on having the service guys from HAAS replace the light bulbs in the machine or something simple like a tool changer finger than any machine will cost dearly. HAAS is easy to work with and almost all parts are available for sale individually. Stock is outstanding.A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X-Carve, 6040, etc . One thing I'm stuck on currently is figuring out material costs. Let's say I want to make a part that needs to be strong and made from at least nylon or similar. Let's say the dimensions are about 1.5"x4"x6". . a CNC part will certainly be stronger .Many things affect the cost of CNC machined parts. See how design, materials, setup needs, time, and more all factor in. 920-726-4526 . Before we dive into CNC machine cost, . the machining costs still apply. Overall machining scrap is .Machine Cost: \text{Machine Cost} = \times 4 \text{ hours} = 0; Tooling Cost: \text{Tooling Cost} = 0 + ( \times 3) = 0; . The finishing processes applied to CNC machined parts play a significant role in determining the final appearance, functionality, and cost of the components. .

round cnc milling cost

I wouldn't buy a Haas ever, but beyond that, get a good used machine. I started with 0,000 @ 4.5% for 48 months from an economic development loan.I would like my cnc machine to be paid off in 3 years. So 3 x 40 x 52 = 6240 hours. Cost of my machine divided by that, plus my monthly maintenance, plus my tooling costs, plus energy costs, plus my regular shop supplies rate that includes things like insurance, heat, garbage bags, and the (solo) company Christmas party. Introduction; What will affect the CNC Machined parts cost? (8 factors) 1. Raw Material Cost 2. Set-Up Cost; 3. Machining Time; 4. Tolerance Requirement

round cnc machining cost

It is typically more cost-effective for low-volume or highly customized work where the time and cost of programming a CNC machine wouldn’t be justified. . because manual tools may not apply consistent pressure or speed, which can lead to errors or defects. . Whether you're producing aerospace parts or consumer electronics, CNC machines . Machine Type: Cost Range: Woodworking CNC Routers: ,000 – 0,000: Metallic & Composite Fabricating: ,000 – 0,000+ Laser CNC Cutting Machines

If you like something more like per hour plus half the new cost of the machine in thousands, that could be closer. That's make a 0,000 machine per hour, a 0,000 machine 0 per hour and a 0,000 machine 0 per hour. But every part and every shop is different. I assume OP is just looking for a ballpark number. Machining Cost for CNC Machines (per part): Machining Time: 2 hours; Setup Time: 0.5 hours; Total Time: 2.5 hours; Cost for Time (2.5 hours * /hour): 5; Material Cost: ; . To determine the optimal hourly cost for labor, various approaches can be applied based on individual circumstances and requirements. 1. Analyzing Labor Rates

Business owner and machinist here. For aluminum parts the material cost is generally 20% of the part cost. What you're paying for is the machine time and the CAM time. Even when you have a template that can just spit out code you . CNC machining is widely employed across various industries for its high accuracy, precision, speed, and efficiency. However, CNC machining services can also be somewhat more expensive when compared to other manufacturing methods such as 3D printing. Cost is a crucial consideration in the application of CNC machining for both one-off or large scale production. .However, they are setup costs and influence the cost of the machining project. The more expensive it is to procure, operate, and maintain a machine, the more expensive parts manufactured with the machine will be. Metalworking CNC .

Compared to traditional CNC milling machines, CNC Machining Centers typically operate along multiple axes, allowing for greater versatility and precision in machining complex parts. . offering both precision and cost efficiency. These axes allow the machine to work on all five sides of a part without the need for additional setups or turning .CNC Machine Cost – Your Comprehensive Guide to Understanding and Navigating Costs. In today’s fast-paced manufacturing world, the utilization of CNC (Computer Numerical Control) machines has become pivotal for businesses and hobbyists alike. . 1 Part 1: The Significance of CNC Machine Costs. 1.1 1.1 The CNC Revolution. 1.2 1.2 The Crux of . However, to provide a general idea, the cost of a typical CNC milling machine ranges from ,000 for basic versions to over 0,000 for more advanced models such as a 5-axis CNC machine. Remember, this is just the cost of the machine itself and doesn’t include operation, labor, maintenance, and material costs.

Discover the true cost of CNC machines. From entry-level to high-end models, find out the prices and factors that influence them. . They’re used in the making of everything from F1 cars to aerospace parts. Many Haas CNC machines cost over 0,000. Hardinge is another brand that produces top-quality industrial CNCs, including milling . This would be a base shop rate + coolant + tooling cost. My base shop rate includes money set aside per month for equipment upgrades, building repairs, etc. so wear on the machine and employee labor is not a factor. Only the actual tooling being worn out. For example: You have a part that has an end mill cutting material for 1 hour non stopYou pay for accuracy & longevity as well as widely available support. edit for clarification & more -> . A hobby machine will not give you +/- 0.00005 accuracy. A hobby machine will not withstand 10+years of continuous 22-24hrs × 6-7days/week operation.

copper sheet metal portland oregon

Obviously, the price tags attached to these machines are not uniform. Machines designed for desktop use are a lot cheaper than machines meant for large-scale metal fabrication or parts production. Thus, the cost of a CNC machine does impact the CNC machining costs. In addition to the initial capital outlay on equipment, machine shops should .

These are the broad factors that determine CNC Machine Cost. CNC Machine Size. The size of the machine, typically measured as the cnc machine’s work envelope (X, Y, and Z coordinate range), is a huge determiner of machine cost. CNC Machines range from tiny in size (small enough to fit on a tabletop) to gigantic (large enough you could drive a .Average Prices for CNC Machines. The cost of a new CNC can differ by the machine manufacturer and its country of origin. Here are the average price ranges for a few different types of CNC machines: How Much Is A CNC Router Machine? Entry-level CNC routers for hobbyists can cost as little as ,000 to ,000. For CNC machined aluminum parts, we can see that from 1 part to 100 parts, we can save -56.37% of the unit price. 100 parts and 1,000 aluminum parts can only save 1.8% of the unit price cost. This shows that increasing the number of parts can significantly reduce the cost of a single part, however the economic benefits decrease for larger .

cost of cnc machining

Plastic (made of polyvinyl chloride, or PVC) is fast becoming the standard material .

cnc machinery cost applied to part cost|round cnc milling cost