cnc machine plc programming While CNC machines are already advanced, the integration of Programmable Logic Controllers (PLCs) can further enhance their efficiency and performance. This blog post explores the .

We will parts of the machining route, process parameters, tool trajectory, displacement, cutting parameters (spindle rotation, feed, return, etc.) and auxiliary functions (tool change, spindle positive, negative, cutting fluid on, off, etc.), according to the CNC machine tools specified instruction code and program format to write the machining .

0 · mitsubishi plc programming examples pdf

1 · cnc programming codes PDF download

2 · cnc milling programming examples pdf

3 · cnc macro programming pdf download

4 · cnc lathe programming pdf

5 · cnc grinding machine programming pdf

6 · cnc drilling program pdf

7 · basic mitsubishi plc programming

Today keys are made out of nickel silver, brass, and steel. Some companies even recycle brass casings to press and create keys. Steel keys require a different, harder blade in order to cut on duplicating machines.

basic i/o ladder logic setup. Centroid’s PLC programming language supports control of advanced CNC control functions which allow extensive customization of the CNC12 software to meet a wide variety of applications. Centroid PLC programming language, compiler and its related real time .In this blog post, we have explored the world of CNC machine PLC programming, covering its basics, programming languages, best practices, real-world applications, and future trends. By .

These specifications are the programming manual used when creating the sequence program with the PLC development software, or Mitsubishi Electric Co.’s integrated FA software .The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming .The first section of the PLC manual will explain programming for the CNC10.PLC program, then move into more complex issues and the PC.PLC or extended PLC programming. LanguageWhile CNC machines are already advanced, the integration of Programmable Logic Controllers (PLCs) can further enhance their efficiency and performance. This blog post explores the .

Explaining the concept of PLC programming and its role in controlling CNC machines. Highlighting the importance of programming languages like ladder logic, structured text, and function block .

Learn PLC Ladder Logic and understand PLC programming and basics of PLC. Sample PLC ladder logic circuits and descriptions available for download. These videos were created to provide an introduction to customizing a Centroid CNC system with PLC edits and macro creation for the power user/integrator. (Custom CNC .

basic i/o ladder logic setup. Centroid’s PLC programming language supports control of advanced CNC control functions which allow extensive customization of the CNC12 software to meet a wide variety of applications. Centroid PLC programming language, compiler and its related real time Logic Analyzer the “PLC Detective” and

In this blog post, we have explored the world of CNC machine PLC programming, covering its basics, programming languages, best practices, real-world applications, and future trends. By understanding the intricacies of PLC programming for CNC machines, manufacturers can unlock the full potential of automation and optimize their machining processes.

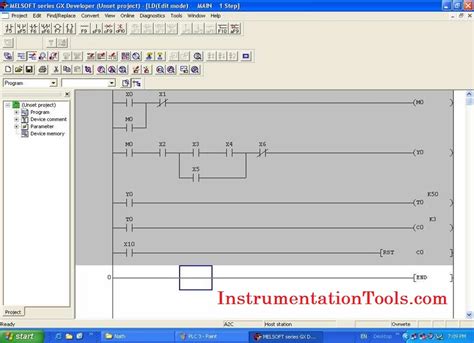

These specifications are the programming manual used when creating the sequence program with the PLC development software, or Mitsubishi Electric Co.’s integrated FA software MELSOFT series (GX Developer). The PLC (Programmable Logic .CNC machines create products and parts at a component level. PLCs, which guide the actions of whole systems. Most CNC machines employ both CNC computers and PLC controllers. CNC programming is used extensively to continuously control each axis position.

The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming examples are used to explain the commands and statements, which are also defined according to DIN 66025. 2. Work preparationThe first section of the PLC manual will explain programming for the CNC10.PLC program, then move into more complex issues and the PC.PLC or extended PLC programming. Language

While CNC machines are already advanced, the integration of Programmable Logic Controllers (PLCs) can further enhance their efficiency and performance. This blog post explores the benefits of using PLC control in CNC machines and offers a comprehensive guide to implementing it effectively. II. Integrating PLC Control in CNC Machines\ III.Explaining the concept of PLC programming and its role in controlling CNC machines. Highlighting the importance of programming languages like ladder logic, structured text, and function block diagram.

Learn PLC Ladder Logic and understand PLC programming and basics of PLC. Sample PLC ladder logic circuits and descriptions available for download. These videos were created to provide an introduction to customizing a Centroid CNC system with PLC edits and macro creation for the power user/integrator. (Custom CNC PLC programs can be.basic i/o ladder logic setup. Centroid’s PLC programming language supports control of advanced CNC control functions which allow extensive customization of the CNC12 software to meet a wide variety of applications. Centroid PLC programming language, compiler and its related real time Logic Analyzer the “PLC Detective” and

In this blog post, we have explored the world of CNC machine PLC programming, covering its basics, programming languages, best practices, real-world applications, and future trends. By understanding the intricacies of PLC programming for CNC machines, manufacturers can unlock the full potential of automation and optimize their machining processes.

These specifications are the programming manual used when creating the sequence program with the PLC development software, or Mitsubishi Electric Co.’s integrated FA software MELSOFT series (GX Developer). The PLC (Programmable Logic .CNC machines create products and parts at a component level. PLCs, which guide the actions of whole systems. Most CNC machines employ both CNC computers and PLC controllers. CNC programming is used extensively to continuously control each axis position.

The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming examples are used to explain the commands and statements, which are also defined according to DIN 66025. 2. Work preparationThe first section of the PLC manual will explain programming for the CNC10.PLC program, then move into more complex issues and the PC.PLC or extended PLC programming. Language

While CNC machines are already advanced, the integration of Programmable Logic Controllers (PLCs) can further enhance their efficiency and performance. This blog post explores the benefits of using PLC control in CNC machines and offers a comprehensive guide to implementing it effectively. II. Integrating PLC Control in CNC Machines\ III.Explaining the concept of PLC programming and its role in controlling CNC machines. Highlighting the importance of programming languages like ladder logic, structured text, and function block diagram.Learn PLC Ladder Logic and understand PLC programming and basics of PLC. Sample PLC ladder logic circuits and descriptions available for download.

mitsubishi plc programming examples pdf

cnc programming codes PDF download

In order for the "tines" on your comb to ring brightly, you must begin with spring steel. You may use a flat piece of steel and cut the teeth into it or use a long length of quality steel bar such as a metal yard rake.

cnc machine plc programming|basic mitsubishi plc programming