cnc machine hour rate calculation formula Calculate by adding the machine’s hourly rate (including depreciation, . $19.99

0 · machinery cost per hour calculator

1 · machine hour rate calculation formula

2 · machine hour rate calculation excel

3 · machine cost per hour formula

4 · cnc router cost per hour

5 · cnc milling cost per hour

6 · cnc machine cost per hour

7 · calculating machine cost per hour

We provide quality commercial and industrial stainless steel cabinets for safe storage. Find counter-height, wardrobe style, and wall-mounted cabinets here. Cart

The CNC Machine Hourly Rate Calculator is an essential tool for accurately estimating costs in CNC machining. By inputting relevant data, shops can determine the total cost of ownership and the final hourly cost with labor.Calculate by adding the machine’s hourly rate (including depreciation, . Learn how to calculate the hourly rate you should be billing your CNC machines for, and how to use it to estimate job costs.As a business owner or operator, it is essential to understand how to calculate the CNC machine hour rate accurately. This guide will walk you through the step-by-step process of determining .

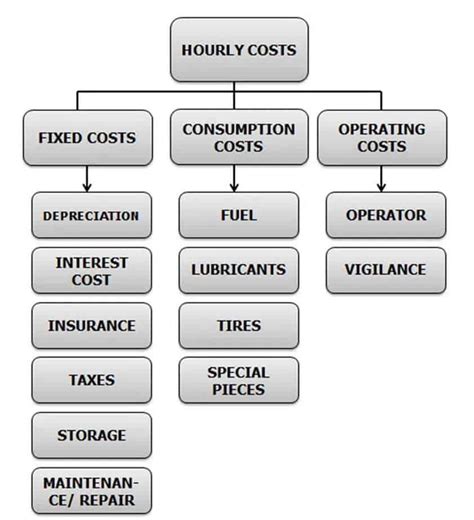

Calculating the CNC machine hour rate is an essential step for manufacturers to understand the true cost of production. By considering fixed costs, variable costs, and machine utilization, .

Machine Hours Rate: Formula, Calculation, Problems and Solutions! The machine hour rate is similar to the labour hour rate method and is used where the work is performed primarily on . Calculate by adding the machine’s hourly rate (including depreciation, maintenance, electricity, etc.), labor cost per hour (operator’s wage), and overhead costs (facility expenses, administrative costs, etc.) divided by .For CNC machine operators and shop owners, understanding the CNC machine hour rate is essential for pricing products and managing profitability. In this comprehensive guide, we will .Below are some points we consider important when calculating the hourly rate for a particular machine. The areas requiring calculations include : Equipment – Cost Per Hour of Operation . a common formula : (machine purchase cost + .

To calculate the CNC machining cost per hour, you need to follow these steps: 1. Determine the machine rate: Start by identifying the hourly rate charged by the CNC machine used for manufacturing. This rate usually . The CNC Machine Hourly Rate Calculator is an essential tool for accurately estimating costs in CNC machining. By inputting relevant data, shops can determine the total cost of ownership and the final hourly cost with labor. Learn how to calculate the hourly rate you should be billing your CNC machines for, and how to use it to estimate job costs. A machine hour rate is the hourly cost in terms of factory overheads to operate a particular machine. It is obtained by dividing the factory expenses associated with the machine for a given period by the number of hours worked by the machine during that period.

sheet metal caulk

As a business owner or operator, it is essential to understand how to calculate the CNC machine hour rate accurately. This guide will walk you through the step-by-step process of determining the hourly rate for your CNC machine, considering various factors that can affect the cost.Calculating the CNC machine hour rate is an essential step for manufacturers to understand the true cost of production. By considering fixed costs, variable costs, and machine utilization, businesses can make informed decisions on pricing, cost optimization, and overall profitability.Machine Hours Rate: Formula, Calculation, Problems and Solutions! The machine hour rate is similar to the labour hour rate method and is used where the work is performed primarily on machines. The formula used in computing the rate is: Factory overhead/Machine hours.

Calculate by adding the machine’s hourly rate (including depreciation, maintenance, electricity, etc.), labor cost per hour (operator’s wage), and overhead costs (facility expenses, administrative costs, etc.) divided by the number of operating hours.For CNC machine operators and shop owners, understanding the CNC machine hour rate is essential for pricing products and managing profitability. In this comprehensive guide, we will delve into the intricacies of calculating CNC machine hour rates using the powerful tool, Excel.Below are some points we consider important when calculating the hourly rate for a particular machine. The areas requiring calculations include : Equipment – Cost Per Hour of Operation . a common formula : (machine purchase cost + expected lifetime maintenance cost) / expected hours of operating life.

To calculate the CNC machining cost per hour, you need to follow these steps: 1. Determine the machine rate: Start by identifying the hourly rate charged by the CNC machine used for manufacturing. This rate usually accounts for the depreciation cost of the machine, as well as maintenance and repair expenses. 2.

The CNC Machine Hourly Rate Calculator is an essential tool for accurately estimating costs in CNC machining. By inputting relevant data, shops can determine the total cost of ownership and the final hourly cost with labor. Learn how to calculate the hourly rate you should be billing your CNC machines for, and how to use it to estimate job costs. A machine hour rate is the hourly cost in terms of factory overheads to operate a particular machine. It is obtained by dividing the factory expenses associated with the machine for a given period by the number of hours worked by the machine during that period.As a business owner or operator, it is essential to understand how to calculate the CNC machine hour rate accurately. This guide will walk you through the step-by-step process of determining the hourly rate for your CNC machine, considering various factors that can affect the cost.

Calculating the CNC machine hour rate is an essential step for manufacturers to understand the true cost of production. By considering fixed costs, variable costs, and machine utilization, businesses can make informed decisions on pricing, cost optimization, and overall profitability.Machine Hours Rate: Formula, Calculation, Problems and Solutions! The machine hour rate is similar to the labour hour rate method and is used where the work is performed primarily on machines. The formula used in computing the rate is: Factory overhead/Machine hours. Calculate by adding the machine’s hourly rate (including depreciation, maintenance, electricity, etc.), labor cost per hour (operator’s wage), and overhead costs (facility expenses, administrative costs, etc.) divided by the number of operating hours.

machinery cost per hour calculator

machine hour rate calculation formula

For CNC machine operators and shop owners, understanding the CNC machine hour rate is essential for pricing products and managing profitability. In this comprehensive guide, we will delve into the intricacies of calculating CNC machine hour rates using the powerful tool, Excel.Below are some points we consider important when calculating the hourly rate for a particular machine. The areas requiring calculations include : Equipment – Cost Per Hour of Operation . a common formula : (machine purchase cost + expected lifetime maintenance cost) / expected hours of operating life.

sheet metal cnc laser cut factory

USA manufacturer of large format laser cutting systems and laser engraver equipment. Specializing in metal and acrylic cutting machines.

cnc machine hour rate calculation formula|machine hour rate calculation excel