sheet metal fabrication tolerance iso standard For sheet metal fabrication, the prevalent standard is ISO 2768. This covers the tolerance requirements for multiple industries while maintaining the perfect balance between costs and processing capabilities. The Zephyr Pyramid Under-Cabinet Vent Hood is a sleek and modern range hood that combines style and performance. With its classic, architectural lines and Perimeter Aspiration System, this hood is perfect for any kitchen that needs an upgrade.

0 · typical sheet metal tolerances

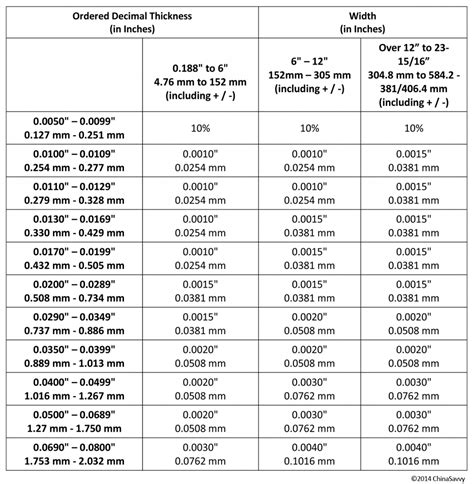

1 · steel plate thickness tolerance chart

2 · standard sheet metal tolerances chart

3 · stainless steel sheet tolerance chart

4 · sheet thickness tolerance chart

5 · sheet metal tolerances chart

6 · sheet metal thickness tolerance chart

7 · astm steel sheet tolerance chart

Premium Material: This dual mount kitchen sink is made of 18-gauge scratch-resistant stainless steel. Its special stain finish hides water spots and maintains a uniform patina over time. The rust-resistant material ensures it won't tarnish or fade. Quiet Sink: Featuring heavy-duty sound guard padding and undercoating, this sink minimizes noise.Whether you’re frying or searing, an undercabinet hood from Lowe’s can help you breathe easy and eliminate harsh odors from your home. Before you shop, determine if you need a ducted .

ISO Standards: The International Organization for Standardization provides a comprehensive standard set for sheet metal fabrication. ISO 2768, which sets benchmarks without specifying individual tolerances for dimensions, is widely used to define general tolerances.You should define tolerance class as per design requirements and manufacturing capability. For example, the manufacturer recommends ISO 2768-mk for sheet metal parts and ISO 2768-fh . For sheet metal fabrication, the prevalent standard is ISO 2768. This covers the tolerance requirements for multiple industries while maintaining the perfect balance between costs and processing capabilities. Here we introduce ISO 2768 standard (General Tolerances for Linear and Angular Dimensions) and ISO 2768 tolerance chart, also provide a free PDF file of ISO 2768 tolerance .

The ISO 2768 international tolerance standard helps engineers and designers simplify the design and manufacturing process by defining acceptable variation ranges between nominal dimensions and other . ISO 2768-1 is intended to simplify drawing indications and specifies general tolerances in 4 tolerance classes (f – fine, m – medium, c – coarse, v – very coarse). It applies for the linear dimensions and angular . “Having a handy guide to compare your called tolerances will profoundly affect your production,” Benson explained. By a “handy guide,” Benson means a guideline specifying reasonable tolerances for a formed part, both for .General Tolerances ISO 2768-1 ISO 2768-1 is intended to simplify drawing indications and specifies general tolerances in 4 tolerance classes (f – fine, m – medium, c – coarse, v – very coarse). . Vacuum Casting, Injection Molding, Sheet Metal Fabrication. Permissible deviations in mm for ranges in nominal lengths Tolerance Class .

For sheet metal fabrication, the prevalent standard is ISO 2768. This covers the tolerance requirements for multiple industries while maintaining the perfect balance between costs and processing capabilities. General . They define the permissible limits of variation in a physical dimension which is a very crucial quality metric in sheet metal fabrication drawings. The International Organization for Standardization (ISO) provides globally recognized standards in sheet metal fabrication through ISO 2768-1:1989. It outlines general tolerances for various aspects .Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. . these are standard tolerances. In many cases, we can tighten these up, but there's usually a cost. So, if you run into a situation where you need tighter tolerances to make your project work - please let us .

Let’s use this box and lid as a sheet metal tolerances case study. This will allow us to analyze the implications of sheet metal manufacturing on achievable tolerances. This assembly is deceiving in its simplicity. As we take a deep dive into the design, take a look at the nuances involved in designing good sheet metal parts.It applies to the dimensions of parts that are produced by metal removal or parts that are formed from sheet metal. NOTES 2 These tolerances may be suitable for use with materials other than metal. 3 Parallel International Standards exist or are planned, e.g. see IS0 60621) for castings.1) All manufacturing tolerances used up to that point (such as laser-cutting tolerances, welding tolerances and more) 2) All bend tolerances for the entire part, added together We call this an uncontrolled dimensions because there are additional tolerances to consider.

The manufacturing process used for specific features in sheet metal fabrication impacts tolerances. While features located on the same surface can achieve standard tolerances of +/- 0.005", formed features like flanges have looser tolerances due to stretching during forming.This part of ISO 10721 establishes a common basis for drafting national standards for the fabrication and erection of steel structures, in order to ensure an adequate and consistent treatment of safety and serviceability compatible with ISO 10721-1.The specific and numerate requirements for the achievement of structures which are optimal with respect to the state of . Tolerances accommodate larger dimensions and processes like welding or fabrication. Plastic components: . and tight fits for rotational balance (ISO 286). Sheet metal parts: Parts made from sheet metal for enclosures, panels, and brackets where tight fits are not critical. . ISO tolerance standards, such as ISO 2768 and ISO 286, provide a .General dimensional tolerances for parts formed by press working from sheet metal Basic size step Grades G rad eA B C Over 1000 to 2000 incl. Over 400 to 1000 incl. Over 120 to 400 incl. Over 30 to 120 incl. . Tolerance for standard dimensions of less t h an0 .5 m s lb ep c if dv u y Over 400 4. General tolerance of perpendicularity JIS B .

typical sheet metal tolerances

With the revision of this ISO. recommendation in 1980, the revision of IS 1731 was also felt necessary. It has now been revised and amalgamated in this second revision of IS 1730, wherein the . 8 TOLERANCES The standard nominal thickness of plates shall be . Table 5 Standard Nominal Dimensions and Mass of Sheet m ( Clause 5.2 ) Sheet Metal Fabrication; Injection Molding; Die Casting; Vacuum Casting; Compression Molding; Get a Quote. Create a new Topic. . ISO tolerance standards, such as ISO 2768 and ISO 286, provide a reliable framework for ensuring consistent quality and precision in mechanical engineering. In addition, GD&T offers more advanced control over part . ISO 2768 is an internationally accepted standard designed to limit the difficulties that arise during manufacturing by introducing standard tolerances for linear dimensions, angular dimensions and for geometrical features. It is relevant in several industries, such as CNC machining, injection molding and sheet metal fabrication. HUDSON, NH — January 15, 2024 Approved Sheet Metal (ASM), a leading national custom precision sheet metal fabrication company based in Hudson, New Hampshire, proudly announces its recent achievement of ISO .

and unequal leg angles - Tolerances for metric and inch series. IS0 1035/IV Hot-rolled steel bars - Part IV Tolerances of round, square and flat bars - Metric series. IS0 657/13 Tolerances on sloping flange beam, column and channel sections. IS0 4995-1978 Hot rolled steel sheet for structural quality. 3

GENERAL TOLERANCES FOR FORM AND POSITION (DIN ISO 2768 T2) STRAIGHTNESS AND FLATNESS Ranges in nominal Tolerance class lengths in mm H K L up to 10 0.02 0.05 0.1 over 10 up to 30 0.05 0.1 0.2 over 30 up to 100 0.1 0.2 0.4 over 100 up to 300 0.2 0.4 0.8 over 300 up to 1000 0.3 0.6 1.2 over 1000 up to 3000 0.4 0.8 1.6

Table of Contents. 1 How Powder Coating Adds Thickness to a Metal Fabricated Part. 1.1 Adjusting tolerances to account for powder coating buildup ; 2 Proactive Designs Pave the Way for Optimal Powder Coating Results; 3 Recommended Default Sheet Metal Tolerances; 4 Sheet Metal Powder Coating Tolerance FAQ. 4.0.1 How does powder coating affect the . ISO 2768-mK means that m and K class tolerances will be used for any dimensions for which tolerances are not given. ISO 2768-1 describes the m class, and ISO 2768-2 describes the K class. ISO 2768-2 also describes the H, K, and L tolerance levels. Here is a brief summary of the ISO 2768-1 and ISO 2768-2 standards: General Tolerances ISO 2768-1

Actual tolerances in sheet metal fabrication are influenced by various factors, underscoring the necessity of engaging with your fabricator at the initial stages of design. . Bend Angles: The standard tolerance for bend angles is ± 0.5°, ensuring precision while allowing for minimal variance. Bend Length: Tolerances for bend length are . ISO 2768-mK means the dimension information for which the tolerances are not specified will be followed according to the m and K class. m class is specified in ISO 2768-1, and the K class is specified in ISO 2768-2, which includes H, K, and L tolerance levels.

Certification Standard for Steel Fabrication and Erection, and Manufacturing of Metal Components December 5, 2016 AMERICAN INSTITUTE OF STEEL CONSTRUCTION 130 East Randolph Street, Suite 2000, Chicago, Illinois 60601 www.aisc.org Supersedes the Standard for Steel Building Structures (AISC 201-06)

utilizing “soft tooling” or standard tooling, turrets lend themselves to both the highly flexible production of prototypes and inexpensive production quantities. Tolerances – The feature to feature tolerance for the turret press is +/-.004”, the punched hole tolerance is +/-.002”.

Unlock the secrets to mastering sheet metal tolerances and ensure precision in your manufacturing processes. Explore the key factors that contribute to top-notch engineering results. . My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for . Here we introduce ISO 2768 standard and ISO 2768 tolerance chart, also provide a free PDF file of General Tolerances for Linear and . It applies to the dimensions of parts that are produced by metal removal or parts that are formed with sheet metal fabrication. ISO 2768 Part 1 only applies to the following dimensions which do not have an . ISO 2768-mK is commonly used in manufacturing sheet metal parts. However, rapid manufacturers also choose ISO 2768-fH for CNC machined parts. Since ISO 2768-mK is a global industry standard, AN-Prototype’s CNC machining services for metals adhere to the ISO 2768-f standard, while plastic parts adhere to the ISO 2768-m standard.

titanium cnc parts manufacturers

steel plate thickness tolerance chart

$259.00

sheet metal fabrication tolerance iso standard|steel plate thickness tolerance chart