cnc flip part and get proper starting point To flip a part, and listen closely, because this is very very tricky. I pick it up... Then flip it over... Its is a very very difficult procedure that should only be performed by those . Welding instructor Mark Prosser, co-author of Full-Bore Welding, walks ARC Magazine readers through the steps to repair a hole in thin-gauge steel.

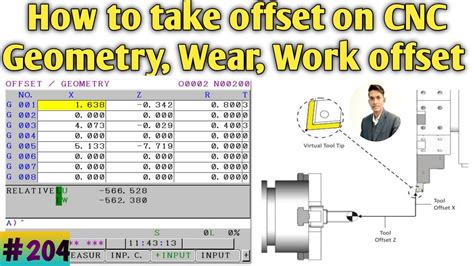

0 · offset in cnc parts

1 · cnc machining practice

2 · cnc machining offset instructions

Through classroom and/or lab/shop learning and assessment activities, students in this course will describe the Shielded Metal Arc Welding process (SMAW); demonstrate the safe and correct setup of the SMAW workstation; associate SMAW electrode classifications with base metals and joint criteria; demonstrate proper electrode selection and use bas.Metal fabrication is an essential manufacturing process and The Federal Group has the capability of shaping metal in a number of ways using state of the art equipment. Below are some of the common metal fabrication processes that we specialize in. See more

OP #1 - set your origin on the part not the rough stock. This requires touching off the stock and then insetting to account for the amount of material you want to remove from x,y and . To flip a part, and listen closely, because this is very very tricky. I pick it up... Then flip it over... Its is a very very difficult procedure that should only be performed by those . You only need to insure that the alignment is constant when you flip it. If you are starting out with square or rectangular stock it is even easier. The only requirement at that .First I drill into the wasteboard with a special toolpath based on the location of the holes. Then I insert dowel pins through the workpiece. I can flip the part and keep perfect alignment. I would .

In this video, Dana shows us the best and easiest way to find the origin/starting point when using your CNC machine. It is very important to know how to find the origin point .I have an operation that requires me to flip the part, and cut from the back, hoping that the outlines match up. To do this, after my first facing op, I bore two 6.03mm holes at 5" apart, and . Be sure in job setup you have chosen the correct settings (material surface vs machine bed/spoilboard surface) & the start location (corner vs center of material) Some . In the "Preview" mode, the toolpath DOES show the proper corner I set the origin point at. However, when I jog the router through the Control Panel to the appropriate corner to .

If your part is not centered in the stock and you flip about the wrong axis, you'd get an offset. Click to expand. The part should be centered in the stock according to the way we set the toolpaths. What is a CNC flip part? In this article we have explained the various types of flip part angles and their dimensions that help in accurate cnc machining. OP #1 - set your origin on the part not the rough stock. This requires touching off the stock and then insetting to account for the amount of material you want to remove from x,y and z. This will account for varying lengths of rough stock. OP#2 - . To flip a part, and listen closely, because this is very very tricky. I pick it up... Then flip it over... Its is a very very difficult procedure that should only be performed by those that have been trained in the difficult art of patting your head and rubbing your belly.

When I put the physical stock in the vise I shunt it up against the stop and touch off the Z height and begin the first op. All seems well at this point, but when I flip the part I make sure the newly machined dimensions are now pressed against the stop and in CAM i set the datum off the model edge. To "flip" the part, just use a new "machine setup" where you change the location of the origin, which also involves flipping the Z axis with the small button to the right of the "Z Direction" button in your Machine Setup settings. You only need to insure that the alignment is constant when you flip it. If you are starting out with square or rectangular stock it is even easier. The only requirement at that point is that the most forward edge remain attached and that it is aligned perfectly with the X axis travel.

First I drill into the wasteboard with a special toolpath based on the location of the holes. Then I insert dowel pins through the workpiece. I can flip the part and keep perfect alignment. I would consider using those threaded holes for guides.

offset in cnc parts

In this video, Dana shows us the best and easiest way to find the origin/starting point when using your CNC machine. It is very important to know how to find the origin point correctly, as it ensures the successfulness of your projects . I have an operation that requires me to flip the part, and cut from the back, hoping that the outlines match up. To do this, after my first facing op, I bore two 6.03mm holes at 5" apart, and then use these to align with the mounting holes in my bed. If your part is not centered in the stock and you flip about the wrong axis, you'd get an offset. Click to expand. The part should be centered in the stock according to the way we set the toolpaths.

What is a CNC flip part? In this article we have explained the various types of flip part angles and their dimensions that help in accurate cnc machining. OP #1 - set your origin on the part not the rough stock. This requires touching off the stock and then insetting to account for the amount of material you want to remove from x,y and z. This will account for varying lengths of rough stock. OP#2 - . To flip a part, and listen closely, because this is very very tricky. I pick it up... Then flip it over... Its is a very very difficult procedure that should only be performed by those that have been trained in the difficult art of patting your head and rubbing your belly. When I put the physical stock in the vise I shunt it up against the stop and touch off the Z height and begin the first op. All seems well at this point, but when I flip the part I make sure the newly machined dimensions are now pressed against the stop and in CAM i set the datum off the model edge.

To "flip" the part, just use a new "machine setup" where you change the location of the origin, which also involves flipping the Z axis with the small button to the right of the "Z Direction" button in your Machine Setup settings. You only need to insure that the alignment is constant when you flip it. If you are starting out with square or rectangular stock it is even easier. The only requirement at that point is that the most forward edge remain attached and that it is aligned perfectly with the X axis travel. First I drill into the wasteboard with a special toolpath based on the location of the holes. Then I insert dowel pins through the workpiece. I can flip the part and keep perfect alignment. I would consider using those threaded holes for guides. In this video, Dana shows us the best and easiest way to find the origin/starting point when using your CNC machine. It is very important to know how to find the origin point correctly, as it ensures the successfulness of your projects .

cnc machining practice

cnc machining offset instructions

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

cnc flip part and get proper starting point|offset in cnc parts