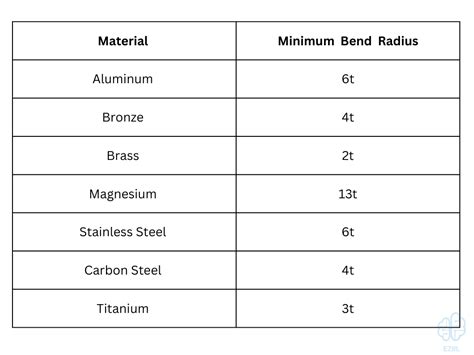

bend radius chart for sheet metal The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for . CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, known as the blank or workpiece, to produce a custom-designed part 1. These computerized machines, called CNC machines, are capable of operating with high precision and consistency.

0 · sheet metal minimum bend length

1 · sheet metal inside bend radius

2 · sheet metal bend radius standard

3 · sheet metal bend radius guide

4 · bending steel plate minimum radius

5 · bend radius vs material thickness

6 · 304 stainless steel bend radius

7 · 304 stainless minimum bend radius

Most screen materials only offer a few options for colors, such as silver, yellowish-gold or brown, and bronze, but fiberglass screens come in almost any color you can imagine. Your contractor can show you the options available for your project’s needs, taking into account the screen style you select.

Check out the reference tables for steel and aluminium below to find out which bend radius is the most suitable for your sheet metal bending projects. In sheet metal fabrication, curving sheets according to a specific .The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for .

Navigate your projects seamlessly with our comprehensive 90° Bend Radius Chart. Accurate, reliable, and easy to understand - a must-have tool for professionals!

RECOMMENDED MINIMUM BEND RADII FOR 90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in .The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. We go beyond the general rules of sheet metal bending, as our .

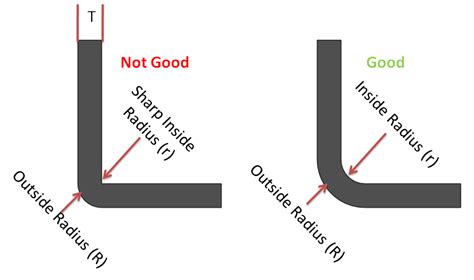

Minimum Bend Radii: The minimum bend radii data contained within the given charts are measured to the inside of the bend. The bend radii listed are standard minimum for .The Sheet Metal Bend Radius Chart is an indispensable resource for anyone involved in sheet metal fabrication. By providing detailed information on material properties, minimum bend .

sheet metal minimum bend length

Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. The bend radius refers to the curvature of a bend and is determined by the .

Sheet Metal Bend Radius Guidelines Here are a few key concepts to know about designing for sheet metal Brackets, covers, cabinets, chassis, electrical enclosures. Check out the reference tables for steel and aluminium below to find out which bend radius is the most suitable for your sheet metal bending projects. In sheet metal fabrication, curving sheets according to a specific bend radius is one of the most common operations used to create flanges, curls, seams etc.

Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs.

The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation, the radius can be near zero for thin sheet metal.

sheet metal inside bend radius

Navigate your projects seamlessly with our comprehensive 90° Bend Radius Chart. Accurate, reliable, and easy to understand - a must-have tool for professionals!

RECOMMENDED MINIMUM BEND RADII FOR 90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in a standard press brake with air bend dies. Other types of bending operations may require larger radii or permit smaller radii.The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. We go beyond the general rules of sheet metal bending, as our customers want tight bend radii for sheet metal parts. It is possible to choose other bends if you require, but additional lead time and tooling charges may apply.

Minimum Bend Radii: The minimum bend radii data contained within the given charts are measured to the inside of the bend. The bend radii listed are standard minimum for manufacturing for aerospace and space applications.The Sheet Metal Bend Radius Chart is an indispensable resource for anyone involved in sheet metal fabrication. By providing detailed information on material properties, minimum bend radii, bend allowances, and K-Factors, the chart enables professionals to make informed decisions and achieve precise, consistent results.

Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. The bend radius refers to the curvature of a bend and is determined by the material type, thickness, and bend angle.Sheet Metal Bend Radius Guidelines Here are a few key concepts to know about designing for sheet metal Brackets, covers, cabinets, chassis, electrical enclosures.

Check out the reference tables for steel and aluminium below to find out which bend radius is the most suitable for your sheet metal bending projects. In sheet metal fabrication, curving sheets according to a specific bend radius is one of the most common operations used to create flanges, curls, seams etc.Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs.The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation, the radius can be near zero for thin sheet metal. Navigate your projects seamlessly with our comprehensive 90° Bend Radius Chart. Accurate, reliable, and easy to understand - a must-have tool for professionals!

sheet metal bend radius standard

RECOMMENDED MINIMUM BEND RADII FOR 90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in a standard press brake with air bend dies. Other types of bending operations may require larger radii or permit smaller radii.The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. We go beyond the general rules of sheet metal bending, as our customers want tight bend radii for sheet metal parts. It is possible to choose other bends if you require, but additional lead time and tooling charges may apply.

Minimum Bend Radii: The minimum bend radii data contained within the given charts are measured to the inside of the bend. The bend radii listed are standard minimum for manufacturing for aerospace and space applications.The Sheet Metal Bend Radius Chart is an indispensable resource for anyone involved in sheet metal fabrication. By providing detailed information on material properties, minimum bend radii, bend allowances, and K-Factors, the chart enables professionals to make informed decisions and achieve precise, consistent results. Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. The bend radius refers to the curvature of a bend and is determined by the material type, thickness, and bend angle.

sheet metal fabricators bellingham wa

sheet metal fabricators adelaide

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters. Each machine has its own .

bend radius chart for sheet metal|sheet metal bend radius guide