benefits of cnc machine Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. Sheet metal fabrication is a set of manufacturing processes for turning sheet metal into functional parts. For this guide, we have divided the processes into three categories: cutting, deformation, and assembly.

0 · disadvantages of cnc milling

1 · disadvantages of cnc machines

2 · cnc milling advantages and disadvantages

3 · cnc machining advantages and disadvantages

4 · cnc machine pros and cons

5 · advantages of cnc milling machine

6 · advantages and disadvantages of cnc

7 · advantages and disadvantages milling process

The first thing you’ll need for a sheet metal shop is a facility to house your equipment and run your business. It’s difficult to put an exact price range on this since it will vary widely based on the location of the facility and its square footage. Plus, you may need to pay for additions to the building to suit the needs of your sheet .

old home has metal electrical boxes

disadvantages of cnc milling

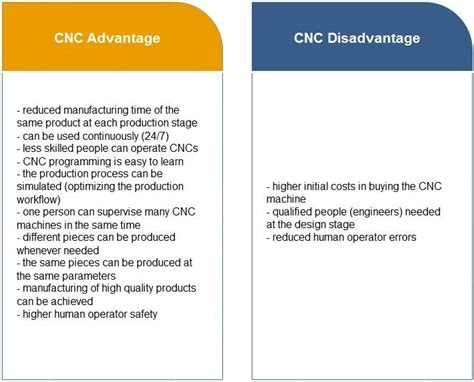

CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry.It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits . CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique . CNC machining has revolutionised manufacturing with its numerous CNC machine advantages when compared to conventional machining. By replacing manual processes with computer numerical control, it offers .

disadvantages of cnc machines

CNC machines have strong adaptability to processing objects, high processing accuracy, stable processing quality, high productivity, high reliability, and can improve working .

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the .

CNC machining and milling is much better than traditional methods of machining. It enables high precision, repeatability and efficiency. Let’s Explore! In this article, we’ll explore the many benefits of CNC machining and milling. These benefits .CNC machining is a highly efficient process that streamlines production, reducing lead times and costs. With the ability to operate around the clock without fatigue, CNC machines can produce large quantities of parts quickly and consistently.

CNC machines allow for incredibly fine measurements and repeatedly replicate exact specifications while maintaining tight tolerances. Several industries demand precision to .CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry.It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits of CNC machining, its applications, and emerging trends. CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries. CNC machining has revolutionised manufacturing with its numerous CNC machine advantages when compared to conventional machining. By replacing manual processes with computer numerical control, it offers precision, consistency, .

CNC machines isolate machines from humans and mitigate the risk that crops up otherwise. These machines can function without an operator, thereby limiting the possibility of accidents and reducing the risk to life and limb. CNC machines have strong adaptability to processing objects, high processing accuracy, stable processing quality, high productivity, high reliability, and can improve working conditions. The CNC unit is responsible for the operation and monitoring of CNC machine tools and serves as its brain. Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the engineer’s arsenal.

CNC machining and milling is much better than traditional methods of machining. It enables high precision, repeatability and efficiency. Let’s Explore! In this article, we’ll explore the many benefits of CNC machining and milling. These benefits include their impact on production volume, labor needs and material use.CNC machining is a highly efficient process that streamlines production, reducing lead times and costs. With the ability to operate around the clock without fatigue, CNC machines can produce large quantities of parts quickly and consistently. CNC machines allow for incredibly fine measurements and repeatedly replicate exact specifications while maintaining tight tolerances. Several industries demand precision to ensure safe, high-quality end products. The aerospace industry relies on CNC to manufacture parts where precision ensures both safety and performance.CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry.It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits of CNC machining, its applications, and emerging trends.

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries.

CNC machining has revolutionised manufacturing with its numerous CNC machine advantages when compared to conventional machining. By replacing manual processes with computer numerical control, it offers precision, consistency, . CNC machines isolate machines from humans and mitigate the risk that crops up otherwise. These machines can function without an operator, thereby limiting the possibility of accidents and reducing the risk to life and limb.

CNC machines have strong adaptability to processing objects, high processing accuracy, stable processing quality, high productivity, high reliability, and can improve working conditions. The CNC unit is responsible for the operation and monitoring of CNC machine tools and serves as its brain. Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the engineer’s arsenal.CNC machining and milling is much better than traditional methods of machining. It enables high precision, repeatability and efficiency. Let’s Explore! In this article, we’ll explore the many benefits of CNC machining and milling. These benefits include their impact on production volume, labor needs and material use.

CNC machining is a highly efficient process that streamlines production, reducing lead times and costs. With the ability to operate around the clock without fatigue, CNC machines can produce large quantities of parts quickly and consistently.

cnc milling advantages and disadvantages

cnc machining advantages and disadvantages

old cnc machine for sale in faridabad

old house metal door frame

Standard metal fabrication materials are:• Plate metal• Formed and expanded metal• Welding wire/welding rod• See more

benefits of cnc machine|cnc machine pros and cons