cnc machine assembly process pdf CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motors As the name implies, an electrical transformer box is a metal unit that contains a piece of electrical equipment called a transformer. When electrical utilities produce electricity and send it out over power lines to our towns and neighborhoods, it’s too powerful for us .

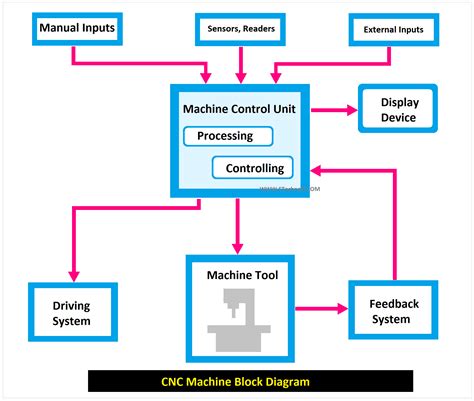

0 · schematic diagram of cnc machine

1 · parts made by cnc machine

2 · explain Mcu in cnc

3 · diagram of cnc lathe machine

4 · cnc mill parts diagram

5 · cnc machine assembly process

6 · block diagram of nc machine

7 · block diagram of cnc machine

What Is Metal Fabrication? Metal fabrication is taking a raw material, typically sheets of metal, through a series of processes to create a finished end product. Virtually every industry relies on metal fabrication to .

CNC Machining Process Guide The following standard machining processes are among the most common techniques used by machine shops today. While many other processes are in use, .CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motors

Introduction & CNC Process Overview Upon successful completion of this lesson, you will be able to: • Describe overall course goal, prerequisites, audience and course design.CNC Machining Process Guide The following standard machining processes are among the most common techniques used by machine shops today. While many other processes are in use, these are the principle methods by which machine shops perform work on metal parts. Turning: Rotating the workpiece to bring metal in contact with the cutting tool.CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motorsIntroduction & CNC Process Overview Upon successful completion of this lesson, you will be able to: • Describe overall course goal, prerequisites, audience and course design.

The first sections of the manual take you through the very basics of what a CNC Mill is and what operations it can do, the basics of how the machine works, what G - Code is, the different types of tools that can be used and other practical things you need to know. This is followed by an overview of the actual TORMACH CNC Mill.* Zip bundle of PDFs and ESAMs. eDrawings (ESAM) is a free 3D format that allows you to rotate, zoom, and take measurements off of the plans. To view the ESAM files, just download the free eDrawings viewer.11. Application of CNC Machine Tools The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame)

Computer Numerical Control (CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing coded alphanumeric data. CNC can control the motions of the work piece or tool, the input parameters such as feed,• classify the various types of CNC machines, • recognize the advantages and limitations of CNC machines, and • define tool handling systems and their uses in CNC machining operations.Learn all you need to know about CNC machining in 25 minutes or less. Whether you are an experienced design engineer or just getting started with CNC, this guide is for you. Short on time? Download for free the PDF version of the Protolabs Network's Engineering Guide .machining instructions for the CNC machine. Once the instructions are ready, operators can load them to the machine and execute the machining operation. For CNC turning and milling operations, the machines facilitate proper workpiece positioning to ensure the parts are machined as per the design. At Impro, our milling and turning

CNC Machining Process Guide The following standard machining processes are among the most common techniques used by machine shops today. While many other processes are in use, these are the principle methods by which machine shops perform work on metal parts. Turning: Rotating the workpiece to bring metal in contact with the cutting tool.CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motors

Introduction & CNC Process Overview Upon successful completion of this lesson, you will be able to: • Describe overall course goal, prerequisites, audience and course design.The first sections of the manual take you through the very basics of what a CNC Mill is and what operations it can do, the basics of how the machine works, what G - Code is, the different types of tools that can be used and other practical things you need to know. This is followed by an overview of the actual TORMACH CNC Mill.* Zip bundle of PDFs and ESAMs. eDrawings (ESAM) is a free 3D format that allows you to rotate, zoom, and take measurements off of the plans. To view the ESAM files, just download the free eDrawings viewer.11. Application of CNC Machine Tools The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame)

Computer Numerical Control (CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing coded alphanumeric data. CNC can control the motions of the work piece or tool, the input parameters such as feed,• classify the various types of CNC machines, • recognize the advantages and limitations of CNC machines, and • define tool handling systems and their uses in CNC machining operations.Learn all you need to know about CNC machining in 25 minutes or less. Whether you are an experienced design engineer or just getting started with CNC, this guide is for you. Short on time? Download for free the PDF version of the Protolabs Network's Engineering Guide .

wago junction box instructions

schematic diagram of cnc machine

wall cabinet steel deep

parts made by cnc machine

CNC stands for Computer Numerical Control and refers to the automated control of machining tools, such as drills, lathes, mills, grinders, routers, and 3D printers, using a computer. The CNC machining process involves inputting coded instructions into a computer, which translates the code into precise movements for the cutting tools.

cnc machine assembly process pdf|parts made by cnc machine