sheet metal standard bend radius Note 1: The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius. If your bend radius . See more Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final shape.A septic distribution box, also known as a D-box, is a small container that receives the effluent from the septic tank and distributes it evenly to the .

0 · sheet metal inside bend radius

1 · sheet metal bending chart

2 · sheet metal bend radius guide

3 · sheet metal bend radius chart

4 · radius of regular 90 bend

5 · large radius sheet metal bending

6 · 304 stainless steel bend radius

7 · 304 stainless minimum bend radius

The automotive power distribution system is built on three main elements - the primary power distribution, the secondary power distribution and the electronic control units (ECUs). The primary power distribution is close to the source, often called the pre-fuse box.

It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Use this document to choose values that are both manufacturable and meet your needs. If you need help choosing a value, contact us at [email protected] 1-866-849-3911 and we can help. . See more

maximum volume of box with 20m 2 of sheet metal

Geometry of tooling imposes a minimum bend dimension. The diagram shows one such mechanism. Refer to the chart for values for folder as well as various press brake tooling . See moreWe’ve broken down our minimum bend radii into two values: minimum hole distance and minimum flange distance. Minimum hole distance specifies how far a hole must be placed . See moreNote 1: The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius. If your bend radius . See more

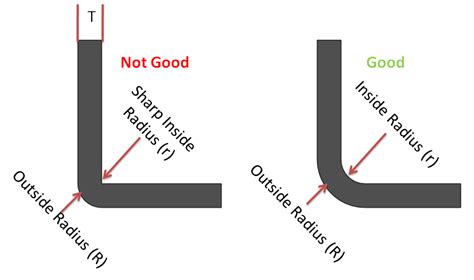

A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius . The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake .The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for .

Design Tips. The Basics of Bend Radii in Sheet Metal. Sheet Metal Bend Radius Guidelines. Here are a few key concepts to know about designing for sheet metal. Brackets, covers, cabinets, chassis, electrical enclosures.

Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural integrity. We use 0.030" for all material .

Bending Radius. To ensure the bending strength of the sheet metal, the bending radius should be greater than the minimum bending radius specified for that particular sheet metal material. The minimum bending radii .

The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. We go beyond the general rules of sheet metal bending, as our . We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, .Sheet metal bend radius: This guide details bending heights, directions, tool interference, bend reliefs, and tolerance stackup.

Here you can specify many of the sheet metal specific properties including bend radius, K-factor, and bend relief dimensions. These can be fixed values or formulas based on the material thickness. (Note: you can find all of . The minimum sheet metal bending height should be calculated as 2 times the thickness of the sheet metal plus the bending radius, i.e., H ≥ 2t + R. As illustrated in the accompanying figure, if the bending height is too low, the .

Sheet Metal Bending Radius refers to the minimum radius that can be applied to a sheet metal component where its flange originates from. Bending radii are usually dictated by available tooling, and for quick and effective .90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in a standard press brake with air bend dies. Other types of bending operations may require larger radii or permit smaller radii. The minimum permissible radii will also vary with the design and condition of the tooling.Recommended inside bend radius for sheet metal parts should be equal to material thickness. For hard materials (Stainless steel, CRCA), an inside bend radius equal to 0.65 times of sheet thickness is also enough.When working with sheet metal, one of the critical parameters to consider is the bend radius. The Standard Sheet Metal Bend Radius refers to the minimum radius that can be achieved when bending a sheet of metal without causing damage or deformation.This article aims to provide a comprehensive understanding of the bend radius for various metals commonly used in sheet .

Factors Influencing the Minimum Bend Radius. The minimum bend radius of the sheet metal is affected by several factors, each of which is of specific importance in determining the most desirable degree of bend that would prevent collapse or paper deformation. tAng factors include:. Material Type: Different materials have varying levels of ductility and tensile strength, .

IV. Press Brake Bend Radius Calculation. The 8 times rule is a general guideline for determining the V-shaped die opening, suggesting that the V-die opening should be 8 times the material thickness. However, there is no exact formula for determining the ideal bend radius for sheet metal, but under certain specified force conditions, the bend radius can be estimated .

sheet metal inside bend radius

Question: My co-workers and I have been reading your columns to help us understand what tooling our shop will need to avoid overstressing our materials with small dies. We air bend our 0.125-inch-thick 5052-H32 aluminum with a 1-mm punch and 16-mm die. Based on your columns, the inside bend radius should be 13 to 15 percent of the die opening. Input Material Thickness and Inner Radius: • Enter the precise sheet thickness and desired inner bend radius. • The calculator will instantly provide the K-factor, Y-factor, and neutral layer position, crucial for accurate bending calculations. . In sheet metal bending calculations, the impact of different material types on the bending .To edit the default bend radius, bend allowance or bend deduction, or default relief type: In the FeatureManager design tree, right-click Sheet-Metal and click Edit Feature . Under Sheet Metal Gauges , select Use gauge table , and select a table .

Working with an included bend angle of 60 degrees, a material thickness of 0.062 in., an inside bend radius of 0.062 in., and a bend allowance (BA) of 0.187 in., you get a negative bend deduction. That means you subtract the negative BD (again, the same as adding) when doing the flat-blank calculation.Yeah you almost certainly can’t manufacture that with traditional sheet metal bending. Your bend radii are also too small and the distance between flanges too close . In your model, use the standard inside bend radius and make the transition in the middle tangent removing the horizontal constraints. Reply reply TheBundyBear77 .Use this sheet metal bending design guidelines when designing your parts for manufacturing. 1. Bend Relief 2. . suitable for designs where the bend radius is not too tight, . Standard sheet metal bending tolerances for reference: Feature: Tolerance: Forming or .Upload your flat pattern with bend lines, or your 3D sheet metal model, to get instant pricing and manufacturability feedback. . Our standard bend angle tolerances are +/- 1.0 degree. Clear Communication, Instant Feedback. .

It’s true that the harder and thicker the plate is, the greater the minimum bend radius. The minimum inside bend radius is even larger when bending with the grain. In steel between 0.5 and 0.8 in. thick, grade 350 and .

The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. We go beyond the general rules of sheet metal bending, as our customers want tight bend radii for sheet metal parts. It is possible to choose other bends if you require, but additional lead time and tooling charges may apply. The Bend Deduction Tables are a series of Excel files defining allowable values and value ranges for things like Thickness, Default Bend Radius, the types of Stamps allowed, and the BendTable which manages deduction values. If you wish to use Bend Deduction values, you need to define a BendTable column, directly after the DefaultBendRadius column.

When bending sheet metal, the inside of the bend compresses and the outside of the bend stretches. To figure the developed length of the bend for the flat pattern of a part. The sin 1 degree x arc x (inside bend radius + 1/3 stock thickness) = developed length around the bend.The bend radius is a critical parameter in sheet metal fabrication, dictating the minimum radius one can bend a metal sheet without significant deformations. Calculating the correct bend radius is essential for ensuring the structural integrity and aesthetic of the finished product. Calculating Bend Radius in Air Forming

Restricting the bend radius to the sheet metal thickness may require us to order specialty tooling. The default bend radius in SOLIDWORKS is 0.100”, a specification that requires specialty tooling to achieve. We recommend changing the bend radius to 0.030”, the industry standard for sheet metal with a thickness of up to 0.125”. Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. . constant; ir – inside radius (mm); t – sheet thickness (mm) Bend allowance formulas: For bends between 0 and 90 degrees, the formula is as follows: ß – bending angle (°) . then by default ISO .

Without setting the sheet metal parameters you can’t invoke the sheet metal tools. The Standard field displays the Standard to use with the part, if implemented. The name of this standard file is defined in a Design Table. . R is the inner bend radius. 6) T is the sheet metal thickness. 7) α is the inner bend angle in radians. 8) β is the . Bend Radius. Fabricators can only bend sheet metal so far before damaging it, and we call that smallest possible inner curvature the bend radius (or internal radius.) You can slash your lead time and avoid the high cost of custom tooling by designing your part’s bend radius to 0.030"—the industry standard for sheet metal up to 0.125" (⅛ . Improve your sheet metal bending operations and achieve precise results every time. . The K-factor for most standard materials and thicknesses typically falls between 0 and 0.5. . bending radius, bending angle, bend allowance, and bend deduction values for common materials. This information is crucial for accurately calculating the .

The standard sheet metal bend formula delivered with Solid Edge is: PZL = * (BR + (NF * THK)) * BA / 180 Where: PZL = Plastic Zone Length. BR = Bend Radius. NF = Neutral Factor. THK = Material Thickness. BA = Bend Angle. Modifying Example Formulas. To modify one of the example formulas delivered with Solid Edge, you must use Visual Basic 4.0 or . To understand why the K-factor cannot exceed 0.5, it’s crucial to comprehend the concepts of the K-factor and the neutral layer in sheet metal bending. Understanding Sheet Metal Bending. Sheet metal bending involves creating a controlled deformation to form a .

sheet metal bending chart

$300.00

sheet metal standard bend radius|large radius sheet metal bending