cnc lathe machine pdf notes The applications of CNC include both for machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, . Disc one1. "Supernaut (Trent Reznor Vocal Version)" – 1000 Homo DJs2. "No Devotion" – Revolting Cocks3. "Beers, . See more

0 · cnc turning program examples PDF

1 · cnc turning machine programming PDF

2 · cnc turning cycle program PDF

3 · cnc programming for dummies PDF

4 · cnc programming PDF free download

5 · cnc machine parts list PDF

6 · cnc machine operation manual PDF

7 · cnc lathe manual PDF

【IP67 WATERPROOF】: Developed for harsh conditions, QILIPSU's electrical enclosure boxes offer excellent protection with an IP67 rating, making them impervious to water and dust. Equipped with the built-in water seal and robust 304 stainless steel latches, these boxes ensure a secure, watertight enclosure for your electrical equipment.

The applications of CNC include both for machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, .A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and .

Computer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine toolsCNC.The applications of CNC include both for machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, laser, sheet-metal press working machine, tube bending machine etc. HighlyA computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and minimal supervision. The same principles used in operating a manual machine are used in . Improvements in the productivity of a multi-tasking machine based on an NC lathe have been achieved by the following, 1) improvement in the performance of the machine tool, and faster.

machine a part • Process plan describes all steps in detail • Includes a description of each operation, the tools required, speed and feed data, workholding information, other notes and comments, and often a sketch depicting the part orientation

In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.Machine Types Lathe The engine lathe, one of the most productive machine tools, has always been an efficient means of producing round parts (Fig. 4). Most lathes are programmed on two axes. •The X axis controls the cross motion of the cutting tool. Negative X (X-) moves the tool towards the spindle

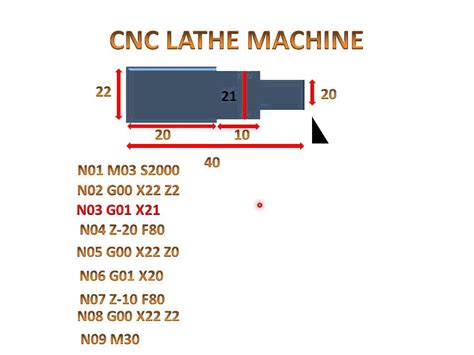

Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment. They may be incomplete or contain errors. Always abide by shop safety instructions and never engage in horseplay.

This document provides an overview of CNC lathes, including their components, safety guidelines, and basic operation and maintenance. It discusses the key parts of a CNC lathe like the bed, headstock, saddle, and tooling.

CNC machine tools allow multiple axes of motion simultaneously, resulting in 2D and 3D contouring ability. • CNC technology also increases productivity and quality control byComputer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine toolsCNC.

The applications of CNC include both for machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, laser, sheet-metal press working machine, tube bending machine etc. HighlyA computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and minimal supervision. The same principles used in operating a manual machine are used in .

Improvements in the productivity of a multi-tasking machine based on an NC lathe have been achieved by the following, 1) improvement in the performance of the machine tool, and faster.machine a part • Process plan describes all steps in detail • Includes a description of each operation, the tools required, speed and feed data, workholding information, other notes and comments, and often a sketch depicting the part orientation

In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.Machine Types Lathe The engine lathe, one of the most productive machine tools, has always been an efficient means of producing round parts (Fig. 4). Most lathes are programmed on two axes. •The X axis controls the cross motion of the cutting tool. Negative X (X-) moves the tool towards the spindleOnly authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment. They may be incomplete or contain errors. Always abide by shop safety instructions and never engage in horseplay.

This document provides an overview of CNC lathes, including their components, safety guidelines, and basic operation and maintenance. It discusses the key parts of a CNC lathe like the bed, headstock, saddle, and tooling.

cnc turning program examples PDF

cnc turning machine programming PDF

Make sure that there is a junction indicator (the small blue dot, not just a geometry node) at the very end of the segment. While this one segment does not actually constitute a junction, the small blue dot is a visual indicator to the editor that the end of this segment is properly set up.

cnc lathe machine pdf notes|cnc turning machine programming PDF