metal sheet metal processing This white paper explores the key components of sheet metal fabrication, ranging from the processes to materials, finishes, design tips, and more. Stainless Steel Lunch Box, Leak Proof, 2 Tier Rectangle with Bonus Pod & 3 .

0 · various sheet metal processes

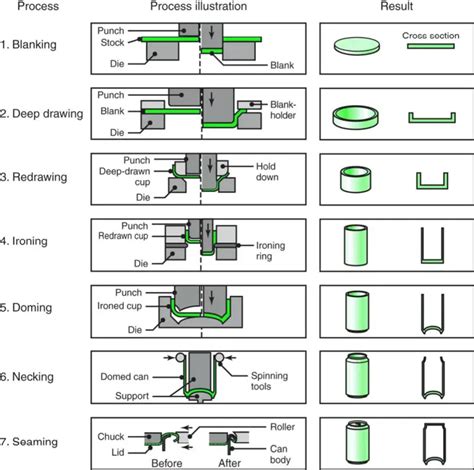

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal process in manufacturing

4 · sheet metal fabrication techniques

5 · sheet metal diagram fabrication

6 · disadvantages of sheet metal

7 · basic sheet metal fabrication techniques

World’s well-known brand spindle motor and imported drills, ensuring precise and stable drilling performance; Utilizing well-known brand touch screen and PCL control system, providing easy operation while reducing failure rate;

various sheet metal processes

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In .Sheet metal fabrication is a versatile approach that begins with the selection of a flat metal sheet, typically steel, aluminum, or stainless steel, and transforms it into the desired component through various processes.

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different .

paul's sheet metal rice lake wisconsin

The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material . This white paper explores the key components of sheet metal fabrication, ranging from the processes to materials, finishes, design tips, and more.Sheet metal processing is a method that manipulates flat sheets of metal into desired shapes and structures. Understanding the sheet metal forming process gives us insights into the world of manufacturing, revealing the ingenious .Custom online sheet metal fabrication services, prototypes, and formed parts in aluminum, copper, brass, steel, and stainless steel. Instant online fabrication quotes, engineering feedback, and free shipping on all US sheet metal forming .

The art and science of sheet metal fabrication involve a series of meticulous processes, from designing and cutting to bending and welding. This article unpacks the top ten technological processes, guiding you through each . Have you ever wondered how everyday items like electronics, cars, and medical devices are made so precisely? The answer lies in sheet metal fabrication. This blog delves into 24 key techniques, from bending and laser .

Metal sheet defects impair the efficiency of downstream processing, so leveling your metal parts after processing is essential. Click here to learn more! 24h customer hotline +1 513 638 8554 MAXPOWER Sheet Metal Bender, 3-Inch Offset Metal Bender Sheet Metal Hand Seamer for Bending and Flattening Metal, Sheet Metal Bending Tool with Ergonomic Handle 4.1 out of 5 stars 39 4 offers from .98

Dongguan Jiatong Precise Metal Products Co. is a trustworthy service provider offering a full array of sheet metal processing operations. Utilizing advanced equipment and industry expertise, we perform laser cutting, sheet metal .Sheet metal processing in Switzerland: precision and efficiency to perfection. For years, our company has established itself as a pioneer in sheet metal processing and sheet metal fabrication in Switzerland. With the highest level of commitment and technological expertise, we realise sheet metal work that is second to none in terms of quality . Sheet metal processing commonly used materials are cold rolled sheet (SPCC), hot rolled sheet (SHCC), galvanized sheet (SECC, SGCC), copper (CU), brass, red copper, beryllium copper, aluminum plate (6061, 6063, hard aluminum, etc.), stainless steel.Our team of skilled professionals, with years of experience in sheet metal fabrication, is dedicated to delivering top-quality results for your projects. 2. Advanced Technology. We employ cutting-edge equipment and techniques, ensuring your sheet metal components are produced with precision and efficiency. 3. Custom Solutions

Microscopic close-up of mild steel sheet metal. Sheet metal is metal formed into thin, flat pieces, . It is commonly used in chemical processing equipment, light reflectors, and jewelry. [5] Grade 3003-H14 is stronger than 1100, while maintaining the same formability and low cost. It is corrosion resistant and weldable.Flexible tool concepts for flexible sheet metal processing. TRUMPF mainly focuses on machine tools for flexible sheet and tube processing. In addition to systems for bending, punching, and for combined punch laser processes, we offer systems for laser cutting and laser welding applications. We provide customers with tailored machines and .

Pasirmas Metal Industry is a new and thriving metal processing company that offers high quality, tailored perforation solutions. Established in 2017, we aim to support the growing demands for perforated sheets across a vast range of industries such as architectural, acoustics, agricultural, food processing, manufacturing and others.

Sheet Metal Processing. The sheet metal fabrication machines make holes of various shapes in sheet metal, cut sheet metal, or bend sheet metal. Knives to bend sheet metal are called tools. Laser Machines. Machines to open holes and cut or weld thin sheets of metal (sheet metal) using a laser beam. Carbon dioxide lasers are often used for .

Capps Manufacturing is an experienced sheet metal processing facility in Wichita, KS providing aircraft sheet metal part finishing & testing. Our aircraft sheet metal fabrication capabilities and equipment allow us to complete many components in-house from start to finish. Since 1983, we’ve served business, commercial and military aircraft companies all over the world.Laser cutting is a metal fabrication process that uses a thin, computer-controlled laser to cut through metal—such as stainless steel, aluminum, and more. The material melts, burns, vaporizes, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Laser cutting is an efficient sheet metal processing technique.Metal spinning is a very old craft. Particularly in the production of parts with rotational symmetry - small and medium quantities - metal spinning is superior to other methods. In metal spinning, a sheet metal disc is pressed centrically - with the pre-spinner - against the spinning mold and set in .Perforated metal sheet . Metal laser cutting processing. Customized metal mesh product. Stainless steel wire Johnson Wedge Wire Screen Panels. . Hengshui from Shanxi weaving factory, bought a weaving machine and opened a processing workshop.He is a very good person. From helping others with weaving and processing to selling by himself, he .

Who We are Professional CNC Sheet Metal Stamping fabricator. Professional engineering team, advanced manufacturing equipment, fully automated production, maximize efficiency to provide you with metal processing services.Modern CNC machinery used for sheet metal processing grant top quality and efficiency of work in cases of complex workpieces. We have the potential of delivering full product fabrication by using CNC laser cutting, CNC puncing presses and press brakes and ofcourse the final processing of steel metal sheet workpieces, including all indurstiral surface treatments. surface .Principles of Incremental Sheet Forming Incremental Sheet Forming is a versatile manufacturing process that involves the gradual deformation of a metal sheet using a localized tool. Unlike traditional forming processes that utilize dies and .

Increasing production flexibility is one of the most important trends in the development of modern sheet metal forming 1.The change from rigid production chains to flexible production steps and .Processing. We have expert engineers, complete production equipment and first-class manufacturing technology. We are equipped with the most advanced computer numerical control punching/perforating machines and photo-etching machine to produce perforated net screens in good quality at favorable price. The punching machines can be light, medium-sized, heavy-duty.

We are a Latvian metalworking, sheet metal processing and fabrication company. We offer metal laser cutting, bending and folding and fabricated part aftertreatment services. Our end product is sheet metal parts: blank pieces made to the client’s individual or standard specifications. We have been working with sheet metal since 2010.ALTEC Metalltechnik GmbH | Grüne Gasse 1 | 07907 Schleiz, OT Crispendorf | Germany +(49) 3663 4210-0 info @ altec-metalltechnik.de. ALTEC has been there for you as a high-performance company in the metal industry for 30 years. Benefit from our experience and expertise in your sheet metal processing projects.

Sheet metal processing. When fantasy is the limit. At INPLAF, thanks to the know-how acquired over more than 40 years of activity, we carry out sheet metal processing with the help of efficient and high-performance machinery. In fact, our large fleet of machines allows for any production that is technically and physically feasible.Advanced sheet metal manufacturing equipment for you. Laser-cutting machines In order to process your products better and faster, HUAYI has purchased 5 laser-cutting machines, two of which were imported. Bending machines We have more than 20 bending machines, half of which were imported, for bending the most perfect sheet metal parts for you.

Initially Chungpu focused on precision sheet metal processing and has over 30 years of experience in high-quality manufacturing. We are recognized as one of the proficient companies in Taiwan's machinery processing industry, known for our technical expertise. Our company specializes in metal plate processing, laser cutting, wire cutting, NCT .

Sheet Metal Fabrication. Utilizing our well-equipped fabrication plant, we offer customers a full catalog of value-added sheet metal fabrication services. Simply provide us with your drawings or design requirements and we will then complete one-stop sheet metal fabrication services. Some of these processes include:Focused on CNC machining parts, metal stamping parts, and sheet metal processing and manufacturing for over 16 years Germany and Japan's high-precision production and testing equipment ensure that the precision of metal parts reaches 0.003 tolerance and high quality. To achieve the required sheet metal tolerance in sheet metal part design guidelines, manufacturers must use precise machinery during production. ADH has 20 years of experience in world of sheet metal manufacturing processing machines, including CNC press brakes, shearing machines, and fiber laser cutting machines.

peacock metallic fabric

【Parameters】- Product Name: Wall switch socket, Wall switch socket panel; Model: 86 type; Material: Plastic; Color: White. 【 Feature】- Waterproof outlet cover mainly play the role of protecting the switch socket, protect the switch panel from being corroded by water, dust or other things, etc.

metal sheet metal processing|sheet metal diagram fabrication