the reason for galvanizing sheet metal is to Galvanized sheet metal is a steel sheet coated with a protective zinc layer, which helps prevent rust and corrosion. This coating plays a crucial role in enhancing the material’s durability and lifespan by acting as a shield against moisture, chemicals, and other environmental factors. In . Schmidt handles a wide array of materials including Carbon, Aluminum, Stainless, .

0 · why galvanized metal

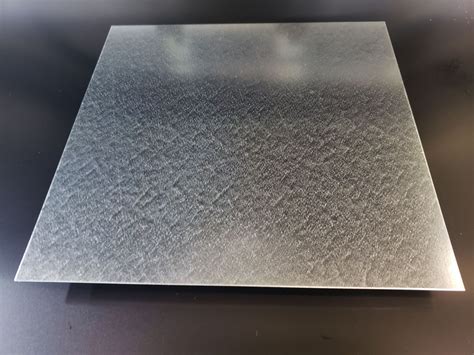

1 · what is galvanized sheet metal

2 · what is galvanized metal

3 · what is galvanized

4 · how does galvanized metal work

5 · how does galvanization work

6 · galvanized sheet metal uses

7 · galvanized sheet metal function

Large variety of metal-wire shopping carts, plastic shopping carts, hand baskets, and shopping cart parts for grocery stores, convenience stores, and department stores.

Galvanized sheet metal is a steel sheet coated with a protective zinc layer, which helps prevent rust and corrosion. This coating plays a crucial role in enhancing the material’s durability and lifespan by acting as a shield against moisture, chemicals, and other environmental factors. In .

Here’s why galvanization matters for sheet metal fabrication: Corrosion resistance: Galvanization helps protect sheet metal from rust and oxidation, extending its lifespan even in harsh .Galvanisation or galvanization (or galvanizing as it is most commonly called) is the process of applying a protective zinc coating to iron or steel, to prevent rusting. The most common . Galvanized sheet metal is one of the most popular types of steel. This is due to its increased strength, extended durability, and formability. The corrosion-resistant property throws its usefulness up a significant notch. Its .» Some Knowledge You Need to Learn About Tapped Hole. What Is Galvanized Sheet Metal? The Complete Basics to Get Started. Galvanized sheet metal is a versatile and cost-effective .

One of the main reasons galvanized steel is so popular is its numerous advantages. We'll discuss these benefits, including its exceptional corrosion resistance, durability, and cost-effectiveness. .Some popular applications include: Roofing and siding: Due to its excellent corrosion resistance and durability, galvanized sheet metal is widely used for roofing, siding, and cladding in both .

why galvanized metal

9 Conclusion. Galvanizing Defined. Galvanized sheet metal parts. The galvanizing process involves the coating of the surface of metals, alloys, or material with zinc to improve its appearance and protect it from rusting.The durability, corrosion resistance, and overall quality of galvanized steel make it an invaluable material for metal fabrication, ensuring that fabricated components and structures remain strong, attractive, and resistant to the damaging effects .Galvanized sheet metal can be used for a number of cooking grill accessories. For example, it can be used to create grilling baskets, drip trays, and tray covers. The metal's rust-resistant nature makes it suitable for creating robust grilling .

One of the questions we hear frequently concerns whether galvanized steel is magnetic, and why or why not. The simple answer is that galvanized steel is magnetic, usually. Explaining why galvanized steel is .What Is Galvanized Sheet Metal? Galvanized sheet metal is a steel sheet coated with a protective zinc layer, which helps prevent rust and corrosion. This coating plays a crucial role in enhancing the material’s durability and lifespan by acting as a shield against moisture, chemicals, and other environmental factors.You can make watertight trays from flat sheet metal without soldering or riviting. Take a sheet of metal whose. length is the length of the finished tray plus two time the height of the sides; width is the width of the finished tray plus two time the height of the sides. Fold the sheet so it ends up looking like this: For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. A zinc chloride-based flux will get you the best flow onto the base metal. A great liquid flux that has an active chloride formation like Johnson’s Galvanized Steel Flux is a great choice for galvanized steel. Make sure to brush the flux .

7 Recommended Default Sheet Metal Tolerances; 8 Galvanized vs. Galvannealed Steel FAQ. . For this reason, galvanized steel is often preferred for parts that will be highly visible, such as solar panels. Galvannealed steel is better suited for internal parts (e.g., electrical components) that don’t have strict aesthetic requirements.

I designed a 3 mm thick mounting bracket for one of my products. For this, I need to cut a galvanized metal sheet and bend it 90 degrees. Maybe I am being over cautious, but (per my reasoning) since the galvanized coating is only in the outer section of sheet metal, the 3 mm wide edges will be uncoated, therefore susceptible to corrosion. cuts from many sheared metal edges do this, and galvanizing may even make it worse because the galvanizing coating flakes more than the base steel under pressure. the actual sheared edge under a microscope is a combination of torn, scissor-cut, and flaked metal. it is quite sharp but not smooth at all, and many of the flaked particles are great places for stuff to . Take a look at this recommended galvanized sheet from Amazon: M-D Building Products Galvanized Steel Sheet . . For this reason, hot-rolled steel sheets have a thickness ranging between 1/6 to 5/6 inches, making it useful in tackling delicate functions. . Mild steel sheet is the last type of metal sheet on our list, which can also be . American Galvanizers Association 6881 South Holly Circle, Suite 108 Centennial, Colorado 80112 Phone: 720.554.0900

Welding galvanized sheet metal – At times, achieving consistent and uniform weld may be a challenge. A reason you should monitor the entire welding process to ensure compatibility. . Reason being, fabricated galvanized sheet metal parts are corrosion resistant. At KDMFAB, we will help you get the best parts for your unique applications . A galvanized metal is considered to have a high resistance to corrosion because the zinc coating acts as a shield against moisture and oxygen. . The reason has been the addition of resistance to galvanized steel, which enhances its financial aspect, as there is no need for regular maintenance or replacement of infrastructure or industrial .

Why is galvanized steel poisonous? Galvanized steel is considered poisonous for different reasons. So, let’s see why galvanized steel is poisonous. Zinc coating: Using a zinc coating on the steel is the main purpose for galvanizing. In the galvanizing process, zinc coating is provided to keep the steel protected.Reasons of hot-dip galvanizing steel sheet crack. . bending or repeated bending of the galvanized steel sheet with a smaller core radius results in an increase in the cold working stress. If a part is cracked due to strain aging, this cracking usually occurs directly after hot-plating, but for steel bars, it may also occur at the construction .Advantages of galvanized sheet metal. A galvanized sheet metal is corrosion-resistant. It is tough and long live. It is suitable for a wide range of applications. 1, galvanized sheet metal is Durable. The galvanized steel provides durable .Galvanized sheet metal is metal which has been coated in a protective layer of zinc to prevent rusting and to protect the metal from the elements. Galvanization is typically performed on iron or steel, and steel is often galvanized while in .

Study with Quizlet and memorize flashcards containing terms like Sheet steel is available as coated or uncoated, A digital micrometer indicates the measurement of the barrel and thimble and the digital readout, The _____ gauge system is commonly used for Sheet Metal and more.

Cutting a long metal sheet into smaller pieces for further production leaves exposed and unprotected edges that are prone to corrosion. . Galvanized Metal Is Everywhere for a Reason. Galvanized metal is a popular choice in telecommunications, automotive industry, wind and solar industries, as well as construction. .Galvanized sheet metal is a type of steel that's gone through a chemical process to coat it with a layer of zinc oxide. As a result, galvanized steel won't get rusty as easily as regular steel. The coating also gives the steel a more durable finish. Because of this, galvanized sheet metal is one of the most commonly used types of sheet metal in .

A steel fabrication made up of sheet steel welded to plate or bar-sized shapes is one of the most commonly distorted assemblies by the hot-dip galvanizing process. This is due to the varying thicknesses of the two pieces of material and how they will expand and contract at different rates during the thermal cycling. Too much zinc can lead to flaking The specifications for hot-dip galvanizing do not set a maximum coating thickness, so there is no limit on the thickness of the hot-dip galvanized coating. . Sheet metal parts cool very quickly so they dont usually experience this type of flaking but thick beams and poles can be very susceptible to flaking .

The Ultimate Guide to Galvanized Sheet Metal: Benefits, Uses, and Maintenance Tips. Galvanized sheet metal is a versatile material used in various industries and applications. In this comprehensive guide, we will take a deep dive into the world of galvanized sheet metal, exploring its benefits, common uses, and essential maintenance tips.Let's start unraveling the mysteries .

Technician A says that cold-rolled sheet metal is made using hot-rolled sheet metal. Technician B says that flat sheet metal is stronger than formed sheet metal. A only. 1 / 20. 1 / 20. Flashcards; Learn; Test; Match; Q-Chat; Created by. Tony_5852. . Galvanized sheet metal: Is .

Benefits of Galvanized Sheet Metal. Overall, galvanized sheet metal offers a corrosion-resistant value. It is very tough and long-lived, making it suitable for a wide range of applications. . Galvanized steel offers the most reliable protection from corrosion for several reasons. First, the natural metallurgical reaction makes the process . 2006. A. Sir: There are generally two types of hot dip galvanizing peeling problems: (1)The peeled coating is bendable and the cause is improper cleaning or fluxing of the steel. (2)The peeled coating is brittle (snaps if one tries to bend it to a right angle) and the cause is reactive steel that is too long in the zinc at too hot of temperature.What Is Galvanized Sheet Metal? Galvanized sheet metal is a steel sheet coated with a protective zinc layer, which helps prevent rust and corrosion. This coating plays a crucial role in enhancing the material’s durability and lifespan by acting as a shield against moisture, chemicals, and other environmental factors. Answer: The reasons for white rust formation include putting hot-dip galvanizing together with other corrosive media such as acid-base or salt; damage to passivation film or anti-film; poor .

what is galvanized sheet metal

CNC is short for computer numerical control, a computerized manufacturing process that uses software to control the movements of various types of CNC machines. If you’ve ever asked what is a CNC machine, it’s simple: A CNC machine is simply a machine equipped with CNC technology and capabilities.

the reason for galvanizing sheet metal is to|what is galvanized sheet metal