car body sheet metal material With a typical thickness ranging from 0.5 millimeters to 6 millimeters, sheet metal is a choice material in the automotive industry for its lightweight yet sturdy characteristics, enhancing both efficiency and safety. This groundbreaking new text connects each welding technique to a useful and creative take-home project, making exercises both practical and personal for students'and avoiding the tedium of.

0 · replacement auto body sheet metal

1 · car sheet metal thickness mm

2 · automotive sheet metal thickness

3 · automotive sheet metal near me

4 · automotive replacement sheet metal

5 · aftermarket sheet metal car parts

6 · aftermarket sheet metal body parts

7 · aftermarket automotive sheet metal parts

Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several .

Making an informed decision about using automotive sheet metal fabrication comes from understanding the process. As a result, this article discusses car sheet metal manufacturing and how you choose it to make . Sheet steel – The most used in previous generation for the most part of the body. Even here there are classifications such as cold rolled and hot rolled low carbon steel with . Automotive sheet metal fabrication involves high-precision manufacturing techniques that enable the automotive industry to grow and produce quality parts while .

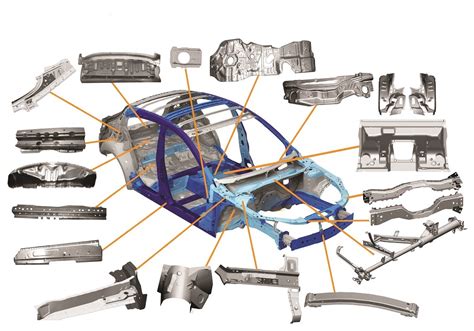

From Body-in-White (BIW) to frames, structural reinforcements, and closure panels: sheet metal is a vital material offering strength, durability, and aesthetic appeal. A vehicle’s BIW and frame use sheet metal to provide the .

With a typical thickness ranging from 0.5 millimeters to 6 millimeters, sheet metal is a choice material in the automotive industry for its lightweight yet sturdy characteristics, enhancing both efficiency and safety.The main parts of the car body are made of steel, aluminum alloys, plastics, and glass. Moreover, the advantage is given to low-carbon sheet steel in the thickness with thickness impact. In this article, you learn how the automotive sheet metal design system evolves & the development of different parts from scratch.

The undulating curves of a sports car or the robust stance of an SUV—all are intricately shaped by the hands of sheet metal artisans. While the visual appeal is undeniable, .The main parts of the car body are made of steel, aluminum alloys, plastics, and glass. Moreover, the advantage is given to low-carbon sheet steel in the thickness with thickness impact.Steel includes not only vehicle bodies, but also engine, chassis, wheels and many other parts. Iron and steel develop the critical components of structure for the bulk manufacturing of vehicles and are low-cost. The best reason for using steel as a body structure is its natural capability to absorb the impact energy produced in a crash. Aluminium: Making an informed decision about using automotive sheet metal fabrication comes from understanding the process. As a result, this article discusses car sheet metal manufacturing and how you choose it to make automotive parts.

Sheet steel – The most used in previous generation for the most part of the body. Even here there are classifications such as cold rolled and hot rolled low carbon steel with different thickness.

replacement auto body sheet metal

Automotive sheet metal fabrication involves high-precision manufacturing techniques that enable the automotive industry to grow and produce quality parts while supporting innovation. Understanding the automotive sheet metal fabrication process is crucial for making informed decisions. From Body-in-White (BIW) to frames, structural reinforcements, and closure panels: sheet metal is a vital material offering strength, durability, and aesthetic appeal. A vehicle’s BIW and frame use sheet metal to provide the necessary structural integrity and rigidity to ensure passenger(s) safety.

metal brackets for poles

With a typical thickness ranging from 0.5 millimeters to 6 millimeters, sheet metal is a choice material in the automotive industry for its lightweight yet sturdy characteristics, enhancing both efficiency and safety.The main parts of the car body are made of steel, aluminum alloys, plastics, and glass. Moreover, the advantage is given to low-carbon sheet steel in the thickness with thickness impact. In this article, you learn how the automotive sheet metal design system evolves & the development of different parts from scratch.

The undulating curves of a sports car or the robust stance of an SUV—all are intricately shaped by the hands of sheet metal artisans. While the visual appeal is undeniable, body panels contribute significantly to the overall performance and safety of a vehicle.The main parts of the car body are made of steel, aluminum alloys, plastics, and glass. Moreover, the advantage is given to low-carbon sheet steel in the thickness with thickness impact.Steel includes not only vehicle bodies, but also engine, chassis, wheels and many other parts. Iron and steel develop the critical components of structure for the bulk manufacturing of vehicles and are low-cost. The best reason for using steel as a body structure is its natural capability to absorb the impact energy produced in a crash. Aluminium:

car sheet metal thickness mm

Making an informed decision about using automotive sheet metal fabrication comes from understanding the process. As a result, this article discusses car sheet metal manufacturing and how you choose it to make automotive parts. Sheet steel – The most used in previous generation for the most part of the body. Even here there are classifications such as cold rolled and hot rolled low carbon steel with different thickness.

Automotive sheet metal fabrication involves high-precision manufacturing techniques that enable the automotive industry to grow and produce quality parts while supporting innovation. Understanding the automotive sheet metal fabrication process is crucial for making informed decisions. From Body-in-White (BIW) to frames, structural reinforcements, and closure panels: sheet metal is a vital material offering strength, durability, and aesthetic appeal. A vehicle’s BIW and frame use sheet metal to provide the necessary structural integrity and rigidity to ensure passenger(s) safety.

With a typical thickness ranging from 0.5 millimeters to 6 millimeters, sheet metal is a choice material in the automotive industry for its lightweight yet sturdy characteristics, enhancing both efficiency and safety.

The main parts of the car body are made of steel, aluminum alloys, plastics, and glass. Moreover, the advantage is given to low-carbon sheet steel in the thickness with thickness impact. In this article, you learn how the automotive sheet metal design system evolves & the development of different parts from scratch.

The undulating curves of a sports car or the robust stance of an SUV—all are intricately shaped by the hands of sheet metal artisans. While the visual appeal is undeniable, body panels contribute significantly to the overall performance and safety of a vehicle.

automotive sheet metal thickness

metal brackets for handrails

metal brackets to hang a light

Wurth USA's Welding Clamp Set is a great solution for easy welding or bonding of sheet metal. This WURTH patented product is a popular tool for vehicle body work. Quick fastening and loosening clamps for enormous time savings in comparison to .

car body sheet metal material|automotive replacement sheet metal