how to measure sheet metal thickness How to Measure Sheet Metal Thickness? There are two ways to measure sheet metal: using a measuring tape (which is less precise) and a . Tsugami Lathe Machines may be the perfect brand for your CNC Lathe Production Needs. We have various Used Tsugami CNC Lathe, Swiss Lathe, Turret Lathe Listings in stock.

0 · sheet metal specifications chart

1 · sheet metal gauge chart thickness

2 · sheet metal dimension chart

3 · plate gauge thickness chart

4 · metric thickness chart

5 · brass sheet thickness chart

6 · brass sheet metal thickness chart

7 · base metal thickness chart

Tri State Roofing takes pride in offering excellent communication and customer service to its clientele. We provide services for residential and commercial roofing, including repairs, replacements, and applications. As we continue to grow, we are eager to partner with customers in Adams, Des Moines, Marion, and Palmyra, maintaining our .

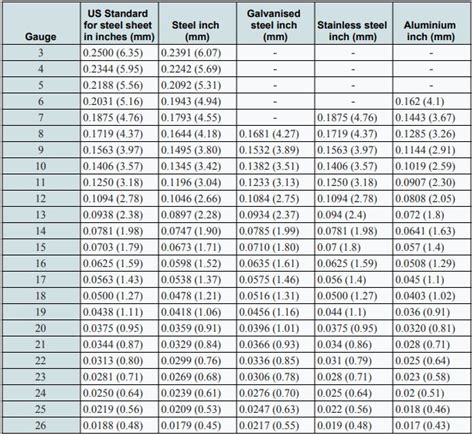

The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.Pure metal / Used as an alloy element for aluminum, lead, zinc, and other . How to Measure Sheet Metal Thickness? There are two ways to measure sheet metal: using a measuring tape (which is less precise) and a . Standard Steel: 16 Gauge = 1.519 mm. Galvanized Steel: 16 Gauge = 1.613 mm. .

Sheet metal gauge charts are invaluable tools in the metalworking industry. They provide essential information about the thickness of the sheet metal to help you choose the perfect measurement for your design. To find out the actual thickness of sheet metal, you can refer to a gauge conversion chart. This chart helps translate gauge numbers, such as 18 gauge, into familiar .

Sheet metal thickness is measured in gauges; the higher the number, the thinner the sheet metal. The most commonly-used sheet metal sizes range from 26 gauge (thinner) to 7 gauge (thicker). A sheet metal gauge tool . A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material thicknesses for various metals. Understanding how to interpret these charts is crucial for .When you need to know the thickness of your metal, a steel gauge chart is your guide. The numbers of a steel gauge chart typically range between 3-30. Yet those numbers do not indicate a specific dimensional value.

Option 1: Using Calipers. Calipers are an accurate measuring tool used to measure the thickness of a sheet of metal. They can provide precise measurements down to the .Use this resource to learn about sheet metal gauges and explore sheet metal thickness charts. Ask us how sheet metal thickness affects your project!

Sheet gauges start at .010” and go up to .170” (or 7 gauge) The thickness for plate sizes can be from .188” and up; . The most precise way to measure a metal’s thickness is to use a caliper. Calipers are hand tools .What I do is check the "Override default parameters" on the sheet metal feature. Then, while in context of the assembly, I double click on the body. This will show your sheet metal dimensions (thickness, radius, and K factor for me). Then you can modify the thickness by double clicking it, and then link it to your assembly level custom property. Solution 1: Measuring Sheet Metal Thickness With Tape. There are three simple steps required in this, and they include: Step 1. Use the millimeter hash marks on your tape to find the thickness of sheet metal. Remember that there are two different measurements on your tape, namely the cm and mm. Using the former will not provide the accurate .

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at . Mitutoyo Sheet Metal Micrometers are used to measure the thickness of sheet metal, paper, plastic, and rubber parts where a deep throat micrometer is required. News. September 17, 2024. In today’s metal industry, gauge and inch measurements are both used to describe thickness. Below, we’ve outlined the distinctions between each method. Measuring Sheet Metal Using the Gauge Measurement System. When purchasing sheet metal, the thickness is typically measured via the gauge system. Unlike other measurements, gauges are not linear.

You can also use a thimble to measure the thickness of sheet metal parts. This will help you find out how thick or thin the part is. You should take note of the distance between the tabs and the bend so that they don’t distort the sheet metal. If you don’t follow these rules, the part might become inaccurate. Recommended Tools & Supplies:Gage Wheel Purchases made using the Amazon links on the OJA website at: www.onlinejewelryacademy.com, help to financially suppo. Step 2: Measure Expanded Metal Thickness. Using a caliper, measure the thickness of the expanded metal sheet or panel. This will help you determine the gauge or wire diameter of the material. Expanded metal is defined by its mesh size, which refers to the distance between two adjacent strands. Measure the mesh size using a ruler or tape measure. The gauge of a sheet of metal is a reference to how thick it is. The higher the numbered gauge a piece of metal is, the thicker the piece is in millimeters. If you want to find out what gauge your sheet metal is, measure its thickness using a regular tape measure.

Metal Thickness Gauge and why you need one! I consider this a must have shop tool. It's a great tool to have in the workshop, on the job site or even while .

To provide metalformers with a reliable and dependable process to instantly and accurately measure lubricant thickness, and to determine its distribution across the complete coil or sheet surface, Amepa GmbH (Amepa America Inc., Middleburg Heights, OH) has introduced an oil-film measurement (OFM) system.Large mills are automated, but some smaller mills still rely on hand-held micrometers to gauge metal thickness. AR200 laser measurement sensors are ideal for measuring steel strip thickness to fine resolutions. Steel passes between two opposing non-contact laser sensors. . The thickness measurement of a plexiglass sheet is a very common .

Sheet metal gauge charts are invaluable tools in the metalworking industry. They provide essential information about the thickness of the sheet metal to help you choose the perfect measurement for your design. For this . In short, when converting a model to sheet metal, Autodesk Inventor 2016 automatically detects the material thickness, versus the “measure and copy” method of previous Inventor versions. Check at the bottom of this . What Is a Sheet Metal Gauge? A sheet metal gauge is a standard unit of measure used to determine the thickness of a metal sheet. The gauge number and thickness have an inverse relationship – the higher the gauge number, the thinner the sheet. For instance, 10-gauge aluminum is 0.1019” thick, while 18-gauge aluminum is 0.040”

sheet metal specifications chart

For example, a 14 gauge sheet of stainless steel is thicker than a 20 gauge sheet. Many sheet metal manufacturers utilize 8 gauge steel or thinner. If you get thicker steel than that, it is no longer referred to as sheet metal and instead is known as plate metal. The thickness of a luminum and other non-ferrous materials is measured in inches . Metal gage is not a preferred method to specify thickness, even though it is commonly listed. The thickness associated with a particular gage value changes with the material specified. 22ga aluminum is not the same thickness as 22ga steel, and is not the same as 22ga zinc coated steel. A gauge is a traditional, non-linear measurement. The most commonly used sheet metal sizes range from 30 gauge (thinner) to 7 gauge (thicker). A sheet metal gauge tool is used to measure metal thickness, and show both the gauge number as well as the thickness of the metal in thousandths of an inch.

: www.elephant-cnc.com www.cncrouter-shop.comEmail: [email protected] Whatsapp/mobile : 0086-15064026772 Skype: elephantcncBLUE ELEPHANT .

Discover the importance of steel gauge charts and how to use them effectively.Hi @knockitover,. Menu > Preferences > Sheet Metal. Part Properties tab, under Global Parameters group you can change the material thickness to the required value. 4 Pcs Double Sided Wire Metal Sheet Thickness Gauge Wire Measurement Tool Portable Metal Gauge Thickness Tool Double Sided Plated Size Inspection Tool Welding Tools Accessories 4.6 out of 5 stars 130 MTI Instruments offers a line of Microtrak laser triangulation sensors that offer high speed, high resolution displacement, position and vibration measuremen.

After you understand a sheet metal gauge, you should learn how to measure the thickness of sheet metal. The sheet metal thickness can be measured using regular tape or a gauge wheel. #1: Measuring Sheet Metal Thickness with Regular Tape. There are three simple steps to measure a sheet metal thickness with regular tape, and they include: Step 1 When measuring the thickness of metal sheets, it's like choosing the right ruler for the job. You want a tool that fits the task, so for metal sheets, a micrometer or a caliper is like the perfect .

metal stand off brackets

metal steel cabinet

Got sum quick questions about installing the sheet metal in a tube car. Do most of you prefer to have it above above or below the frame rails? I was wanting to do it below simply because i run a clutch and wanted to be able to drop it out of the car fast and easily. I am planing on having no trans tunnel just the manditory driveshaft tube.Our RD-series CNC tube bending machines will save you money by providing maximum flexibility while offering the latest in features and advanced technology. Winton’s CNC benders can be .

how to measure sheet metal thickness|brass sheet thickness chart